Environment-friendly and flame-retardant conveying belt with aramid fiber thread rope core and production technology thereof

A kind of aramid thread, environment-friendly technology, applied in the field of flame retardant conveyor belt in mines, can solve the problems affecting the popularization and use of aramid skeleton material, the length of a single roll of aramid canvas should not be too long, and the cost of products will increase, and the joint strength can be achieved. High retention rate, light weight and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

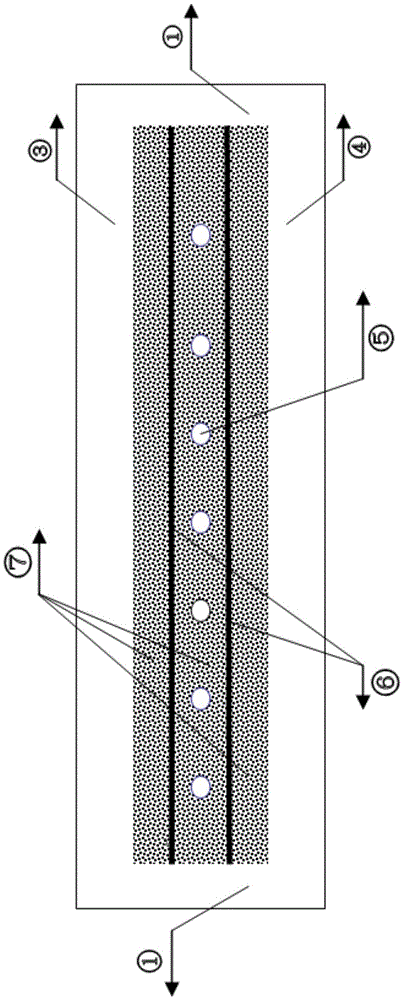

[0027] figure 1The shown environment-friendly aramid cord core flame retardant conveyor belt is composed of an aramid dipped cord skeleton layer 5, a tear-resistant buffer layer 6, an upper covering adhesive layer 3, a lower covering adhesive layer 4 and side glue A layer 1 is formed, and a tear-proof buffer layer 6 is provided on both sides of the aramid-impregnated wire rope skeleton layer 5 respectively. Between the aramid dipped cord skeleton layer 5 and the anti-tear buffer layer 6, between the anti-tear buffer layer 6 and the upper and lower cover adhesive layers and the side adhesive layer 1, pass flame-retardant adhesive glue (conveyor belt structure after molding The middle is the flame retardant adhesive layer 7) bonded and vulcanized to form a whole.

Embodiment 2

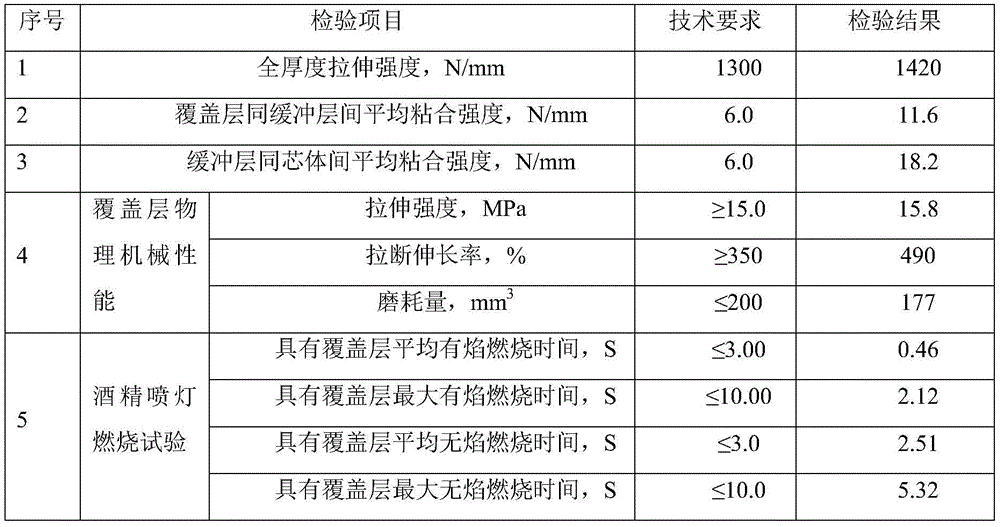

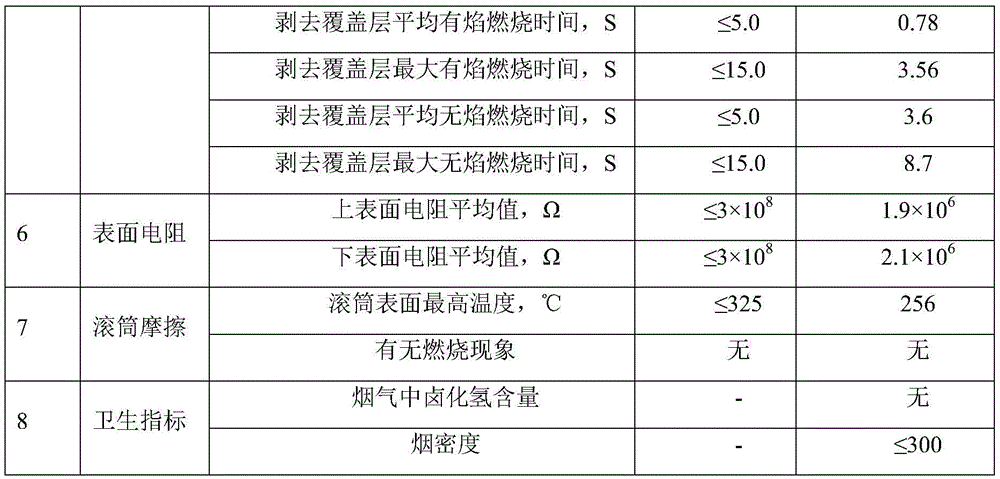

[0029] Originally used 1000mmST / S1000 Flame retardant steel wire rope belt, the safety factor of steel wire rope tape is 6-8 times. Use environmentally friendly flame-retardant aramid cord core flame-retardant conveyor belt instead. The safety factor of the aramid cord structure tape is 8 to 10 times. Considering the safety factor requirements, the breaking strength of the tape is designed to be 1300N / mm. Among them, the aramid dipped cord has a specification model of 1670dtex×4×5, a breaking strength of 4500N, a cord diameter of 2.3mm, and 300 pieces of 1000mm bandwidth. There is a gap of 0.46mm on both sides of the aramid cord for rubber coating. . The thickness of the upper and lower cover glue is the same as that of the steel cord tape, both are 6.0mm, and the buffer tear layer uses ordinary nylon 66 mesh cloth.

[0030] Flame retardant adhesive formula, by weight: 75 parts of natural rubber, 25 parts of butadiene rubber, 5 parts of zinc oxide, 2 parts of magnesium oxi...

Embodiment 3

[0043] Originally used 1000mmEP250×4(6+3) laminated flame-retardant tape, with a strength of 1000N / mm and a safety factor of 10-12 times. Use environmentally friendly flame-retardant aramid cord core flame-retardant conveyor belt instead, and the safety factor of aramid cord structural tape is 8 to 10 times. Considering that the strength loss of EP tape is 15% during the heat vulcanization process, which is much greater than 5% of aramid fiber The strength change, the breaking strength of the belt is designed to be 800N / mm. Among them, the aramid dipped cord has a specification model of 1670dtex×3×5, a breaking strength of 3500N, a cord diameter of 2.0mm, a cord unit weight of 300g / 100m, and a bandwidth of 1000mm using 300 pieces. The two sides of the aramid cord The gap is 0.6mm, and the weight of the cord consumed per meter of tape is 0.9kg. The thickness of the upper and lower cover rubber is the same as that of the laminated belt, and the buffer tear-proof layer uses ordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com