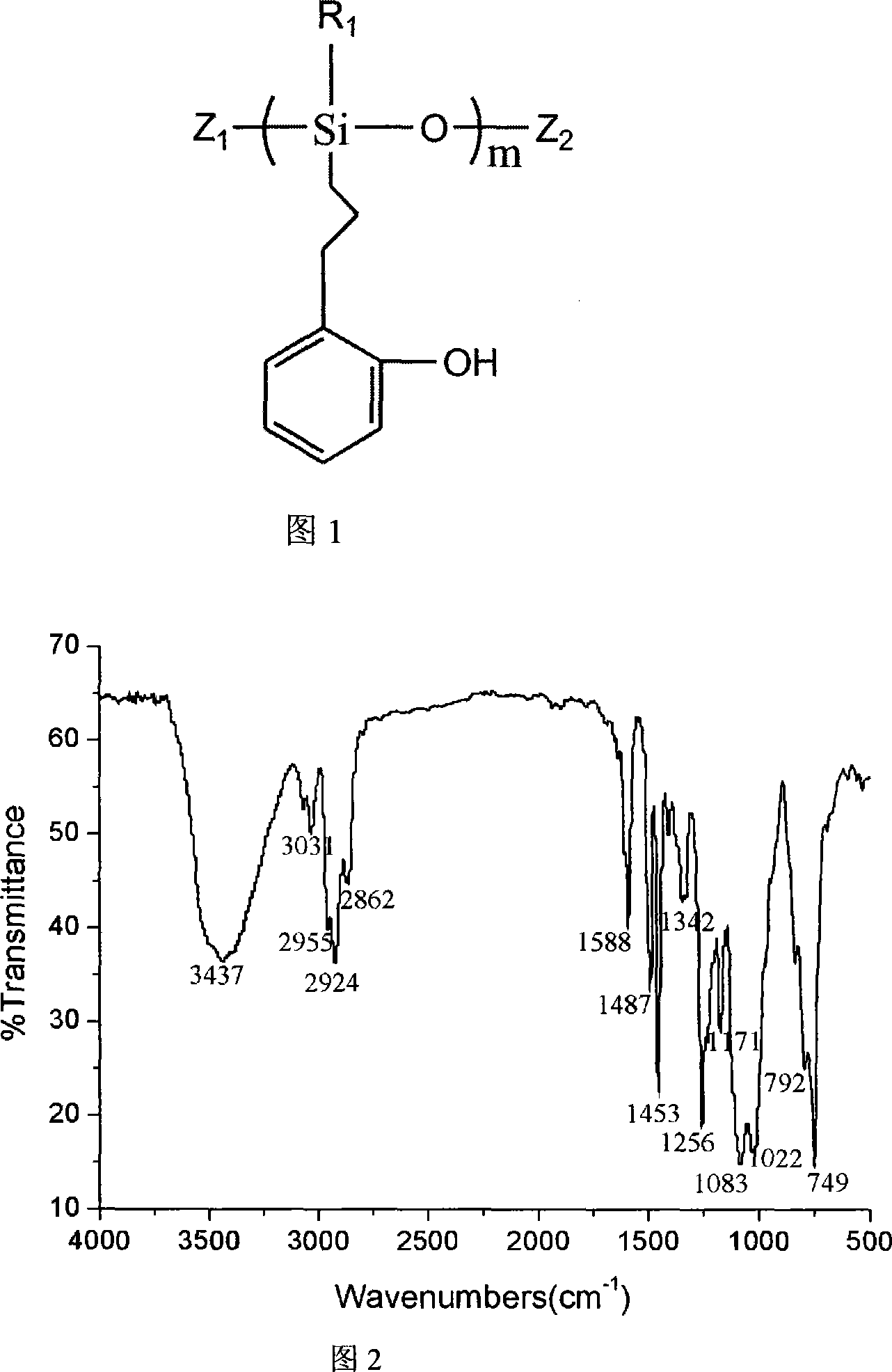

Polysiloxane organic phosphine poison sensitive material and preparation method thereof

A technology of polysiloxane and sensitive materials, applied in the field of materials, can solve the problems of operator and environmental threats, many preparation steps, and complex processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

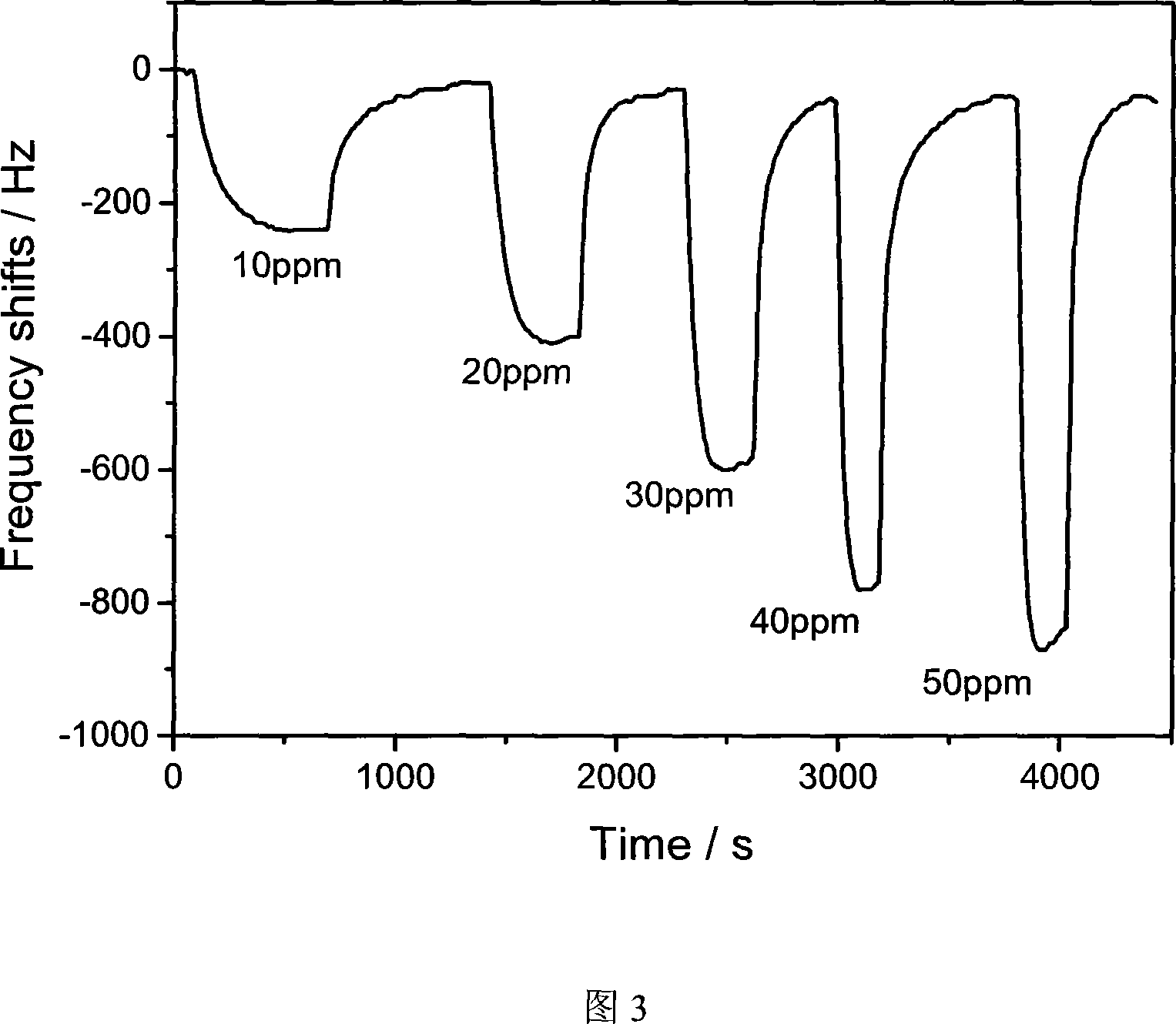

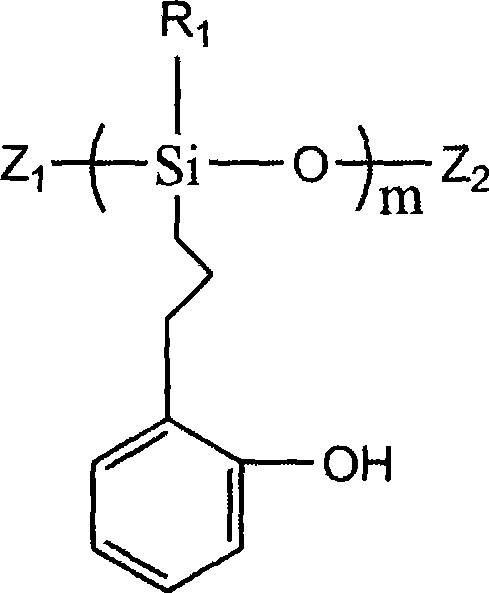

[0042] In a 100ml three-necked flask equipped with a thermometer, a reflux condenser, a constant pressure funnel and a nitrogen protection device, add 0.77g of methyl hydrogen silicone oil (hydrogen content 1.3%) and 1 drop of divinyltetramethyldisiloxane platinum Complex and 20ml of toluene, heated to 80°C, stirred for 0.5h, then slowly added 1.50g o-allylphenol dropwise to the mixed solution, heated to 100°C, stirred for 4h. After the reaction solution was cooled to room temperature, the platinum complex was removed by filtration with activated carbon, and the solvent toluene and other low boiling point substances were evaporated by a rotary evaporator to obtain polymethyl[3-(2-hydroxy)phenyl]propylsiloxane 1.71 g. Its infrared spectrum is shown in Figure 2, and the response curve of the polysiloxane sensitive material coated on the quartz crystal microbalance to dimethyl methylphosphonate is shown in Figure 3.

specific Embodiment approach 2

[0043]In a 100ml three-necked flask equipped with a thermometer, a reflux condenser, a constant pressure funnel and a nitrogen protection device, add 0.63g of phenyl hydrogen-containing silicone oil (hydrogen content 1.6%) and 1 drop of divinyltetramethyldisiloxane platinum Complex and 20ml of toluene, heated to 80°C, stirred for 0.5h, then slowly added 1.50g o-allylphenol dropwise to the mixed solution, heated to 100°C, stirred for 4h. After the reaction solution was cooled to room temperature, the platinum complex was removed by filtration with activated carbon, and the solvent toluene and other low boiling point substances were evaporated by a rotary evaporator to obtain polyphenyl[3-(2-hydroxy)phenyl]propylsiloxane 1.51 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com