Process for producing molybdenum-based sputtering target plate

A manufacturing method and sputtering target technology, applied in sputtering plating, ion implantation plating, coating and other directions, can solve problems such as reducing deformation resistance, and achieve the effect of suppressing edge fracture and efficient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

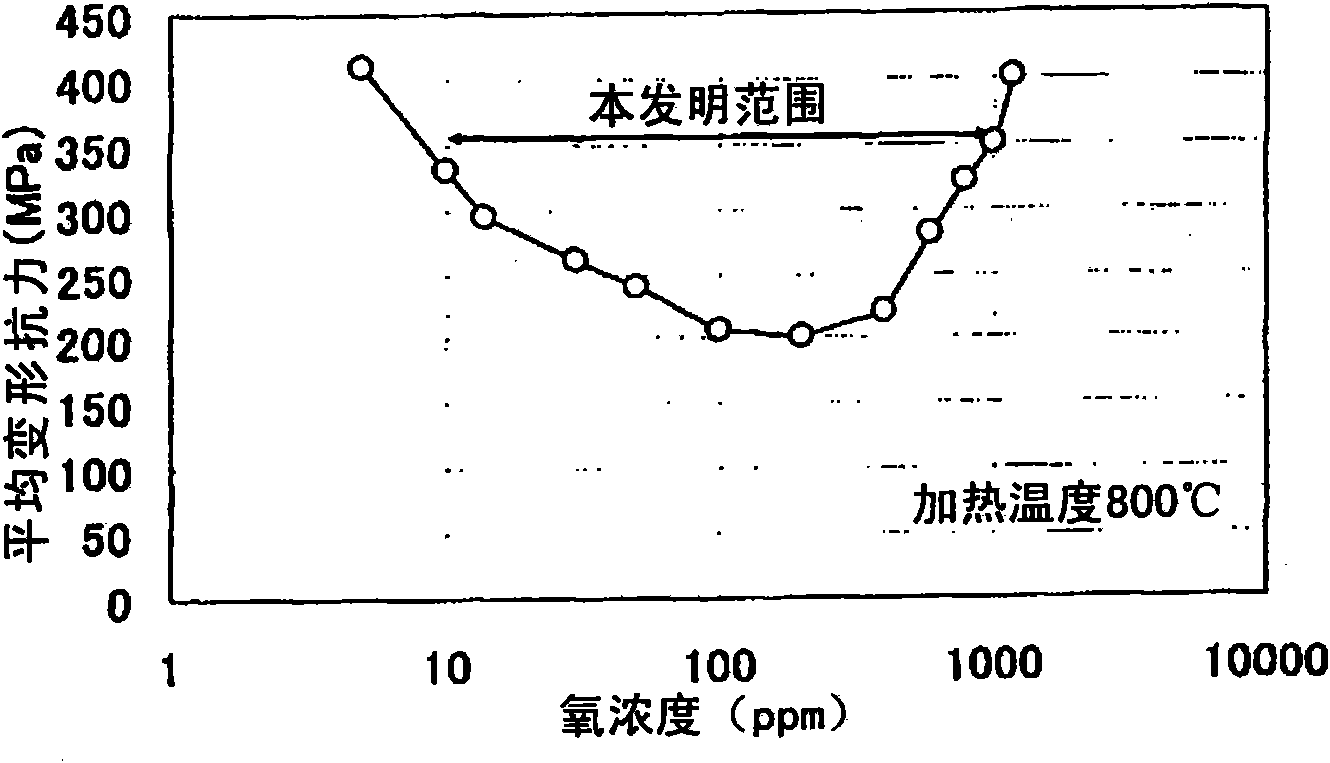

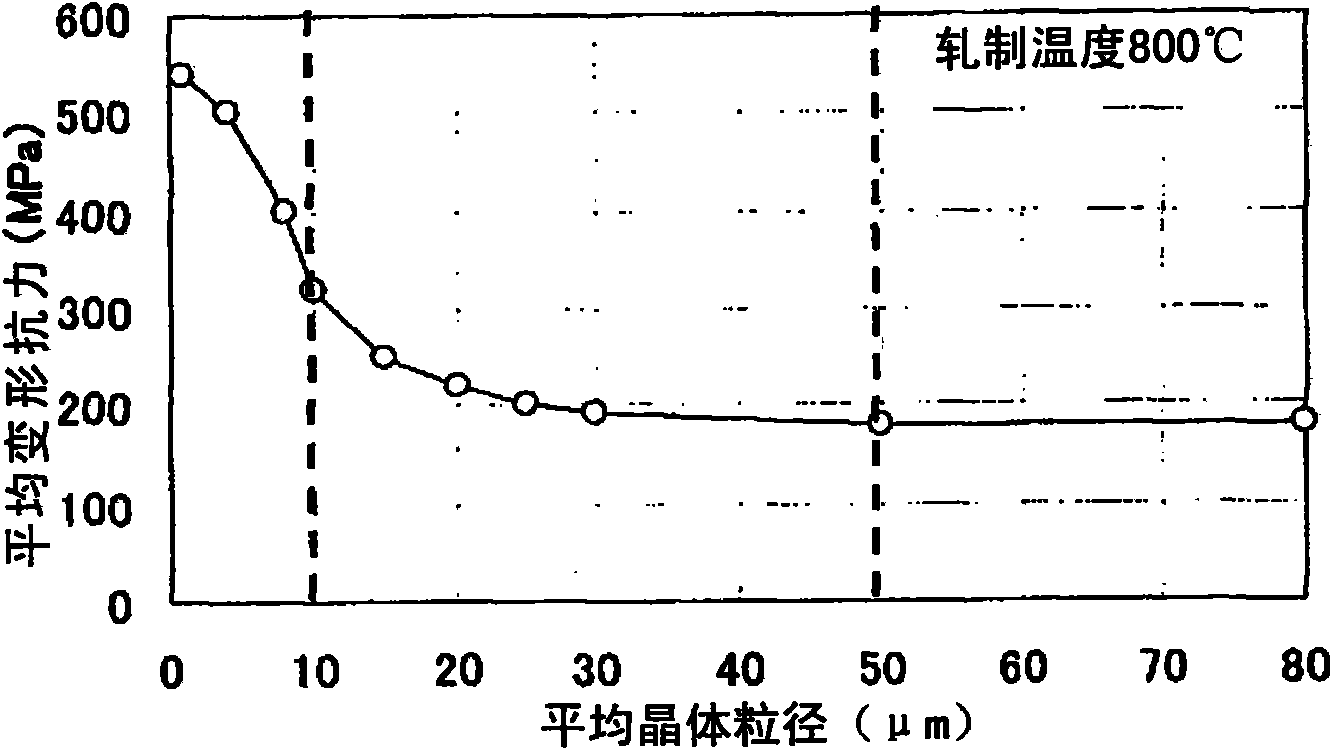

[0073] Using pure Mo powder with an average particle size of 5 μm as a starting material, a manufacturing experiment using a rolled Mo target plate was carried out. The Mo powder is cold-rolled to produce a temporary molded body with a relative density of about 60%. Then, after inserting the temporary molded body into a HIP container made of SS400, the work of controlling the oxygen content was performed. 1500 mass ppm of oxygen was attached to the raw material powder, and after the inside of the container was evacuated, hydrogen was purged and heated to 300°C to reduce the oxygen concentration. The longer the holding time is, the more the oxygen concentration decreases. Therefore, the oxygen concentration is controlled by the holding time, and the oxygen concentration is represented by the oxygen concentration measured in the Mo ingot after pressure sintering. The oxygen concentration was measured inside the ingot surface at a distance of 100 μm or more.

[0074] After per...

Embodiment 2

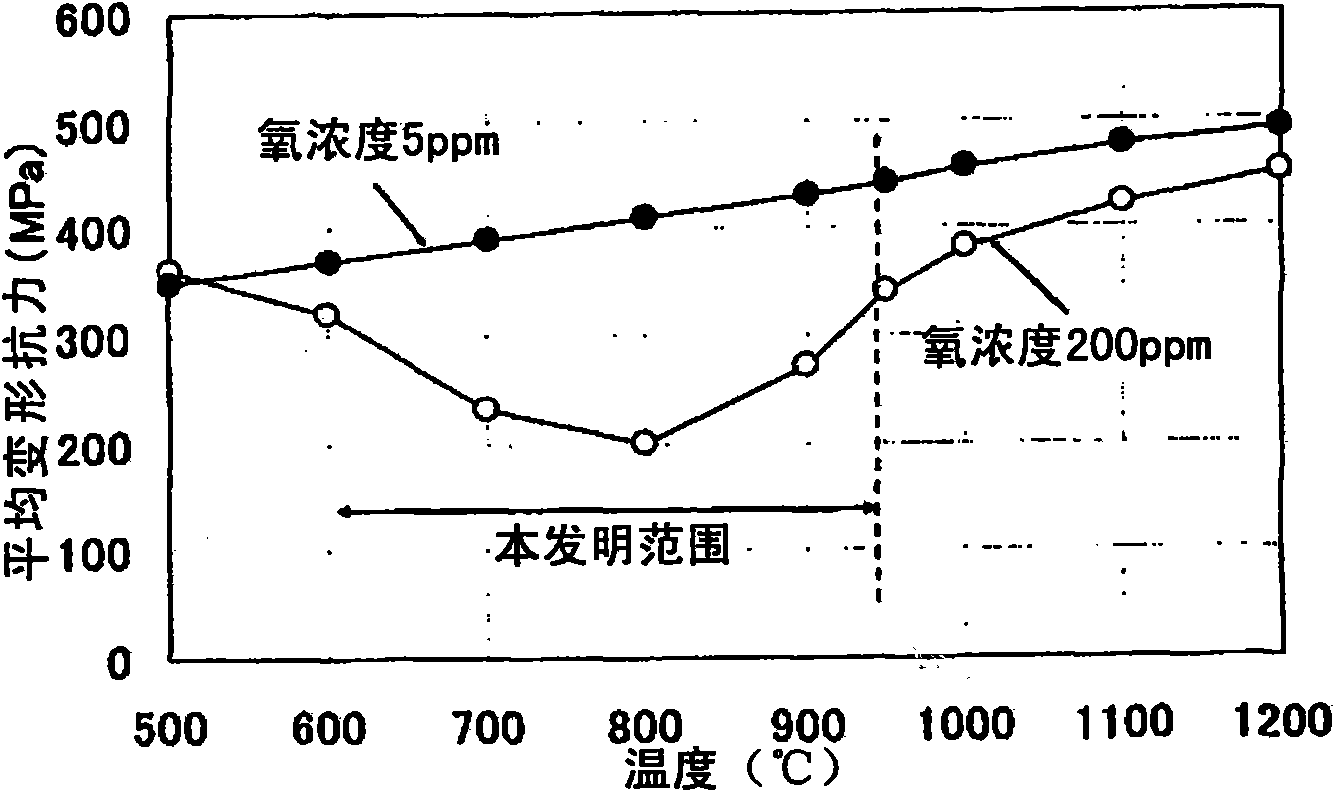

[0101] A plurality of Mo ingot plates were produced under the same production conditions as in the invention example of No. 7 of Example 1, and an experiment for confirming the effect of reheating during rolling was implemented. The oxygen concentration contained in this Mo ingot was 200 mass ppm. This oxygen concentration is a value measured inside the surface at a distance of 100 μm or more. In addition, the average crystal grain size of these ingots measured by the line segment method was 19 μm. The size of the Mo ingot was 220 mm wide x 1400 mm long x 30 mm thick.

[0102] First, the Mo ingot was reheated at each temperature between 1000°C and 1300°C, and kept for 1 hour. Reheating was performed in the atmosphere using an electric furnace. In order to study the compression deformation resistance of each ingot after reheating, a small test piece was cut out from the ingot after reheating, and the S-S curve during compression was measured at the same temperature as the ro...

Embodiment 3

[0122] An experiment of producing a Mo-based sputtering target plate was carried out by rolling a Mo-based ingot made of an element having a mass ratio of Mo:W=80:20.

[0123] The starting materials are pure Mo powder with an average particle size of 5 μm and pure W powder with an average particle size of 8 μm. These are well stirred with a ball mill to prepare mixed powder. The mixed powder is molded by cold isostatic pressing to produce a temporary molded body with a relative density of about 60%. In addition, the temporary molded body was inserted into a HIP container made of SS41, and the oxygen content was controlled. The oxygen concentration of the mixed powder was 3 mass ppm, and the inside of the container was directly heated to 300° C. in an air state to oxidize it. The longer the retention time, the more the oxygen concentration increases. Here, the oxygen concentration is controlled by the holding time, and the oxygen concentration is represented by the oxygen conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com