Semiconductor laser and manufacturing method thereof

A semiconductor and laser technology, applied in the field of semiconductor lasers and their manufacturing, can solve problems such as cavity surface degradation and degradation, and achieve the effect of improving reliability and saving lithography steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

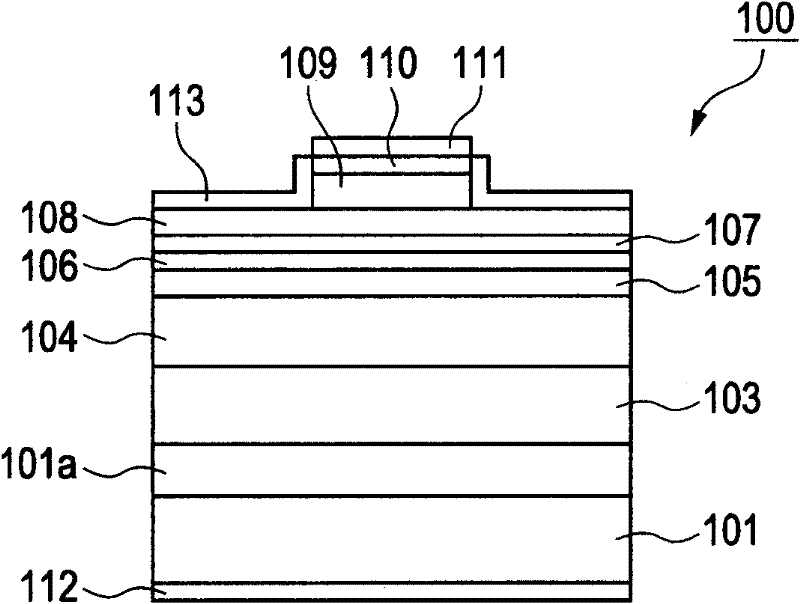

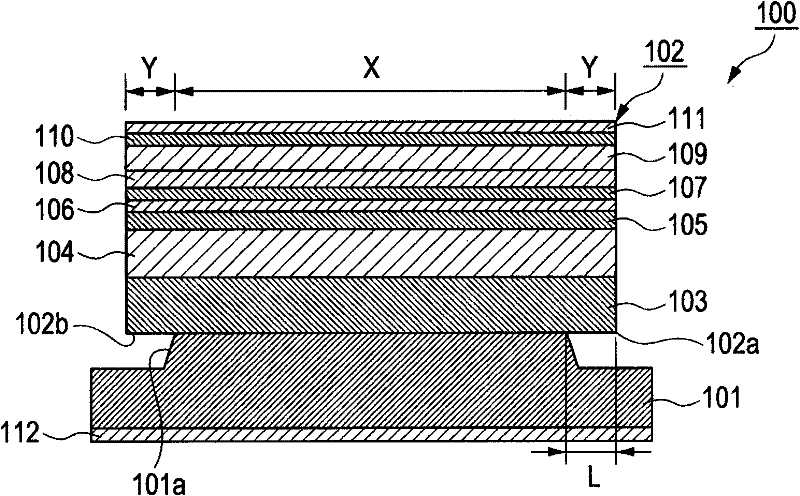

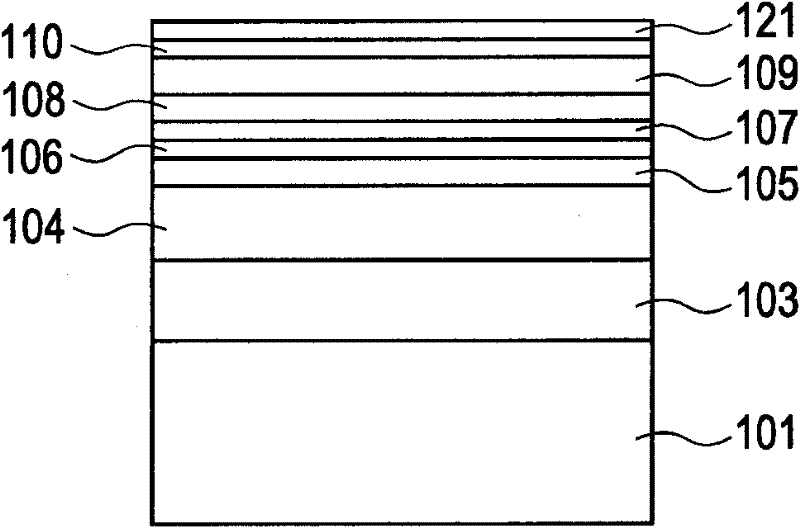

[0027] In a preferred embodiment, the semiconductor substrate has a recessed region below the facet of the resonator, such that the semiconductor substrate does not contact the resonator.

[0028] In a preferred embodiment, the recessed area corresponds to the location of the non-current injection area and the window area for the resonator.

[0029] In a preferred embodiment, the resonator has a lower cladding layer and an active layer formed over the lower cladding layer. A length from an end surface of a region not in contact with the semiconductor substrate at the lower surface of the resonator is smaller than the thickness of the lower cladding layer.

[0030] In a preferred embodiment, the length from the end face of the region at the lower surface of the resonator not in contact with the semiconductor substrate is less than 20 μm.

[0031] In a preferred embodiment, the semiconductor laser also has a first electrode electrically coupled to the resonator and a second ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com