Battery case packaging material for cold molding comprising biaxially-stretched polybutylene terephthalate film

A technology of polybutylene terephthalate and biaxial stretching, which is applied in the field of battery packaging materials, can solve the problems of pinholes or cracks, uneven deformation of aluminum foil, etc., achieve stable formability, and inhibit the breakage of aluminum foil or pinholes, the effect of ensuring formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] (Preparation method of PBT unstretched film before stretching)

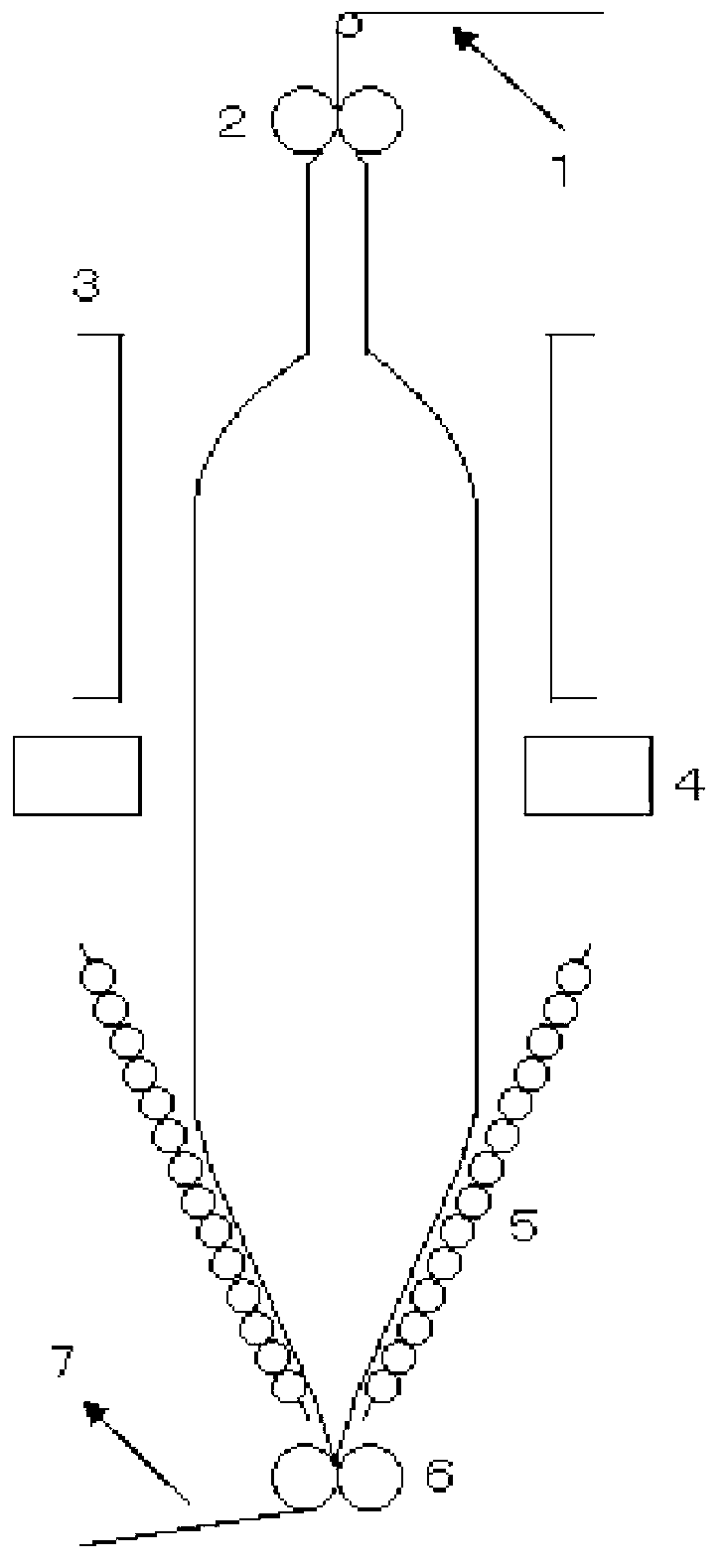

[0032]In order to stably biaxially stretch the PBT resin, it is necessary to suppress the crystallization of the unstretched film before stretching as much as possible. The crystallization temperature range of the polymer, that is, the cooling rate of the film before stretching is an important factor. The cooling rate of the film before stretching is above 200°C / sec, preferably above 250°C / sec, especially preferably above 350°C / sec. Crystalline state, so the stability of bubbles rises rapidly when stretched. Furthermore, since film formation can be performed at high speed, productivity is also improved. When the cooling rate is less than 200°C / sec, not only the crystallinity of the obtained unstretched film before stretching becomes high, but also the stretchability decreases, and in extreme cases, the stretching bubbles are broken, and the stretching cannot be continued. Any method that satisfies the c...

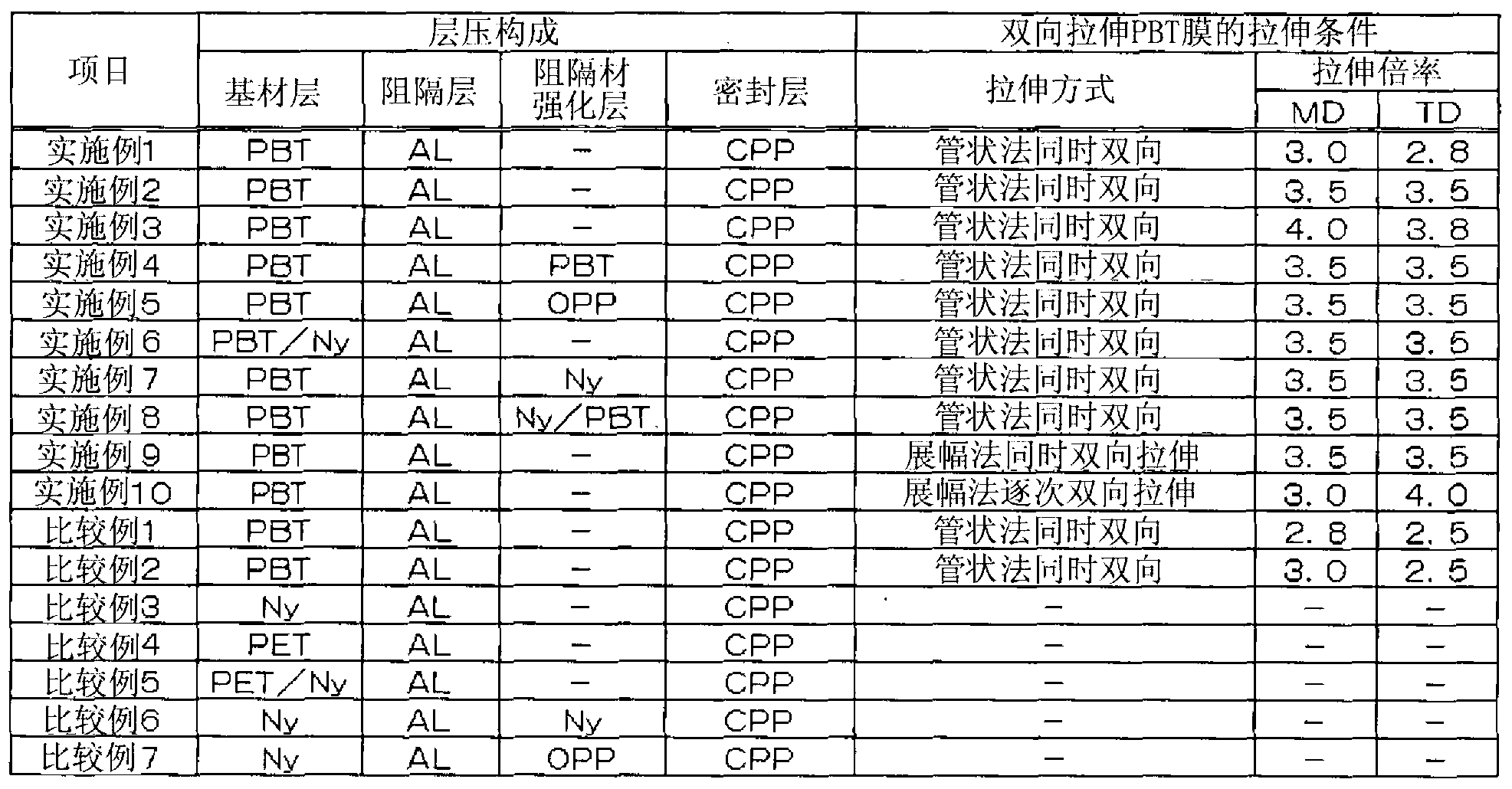

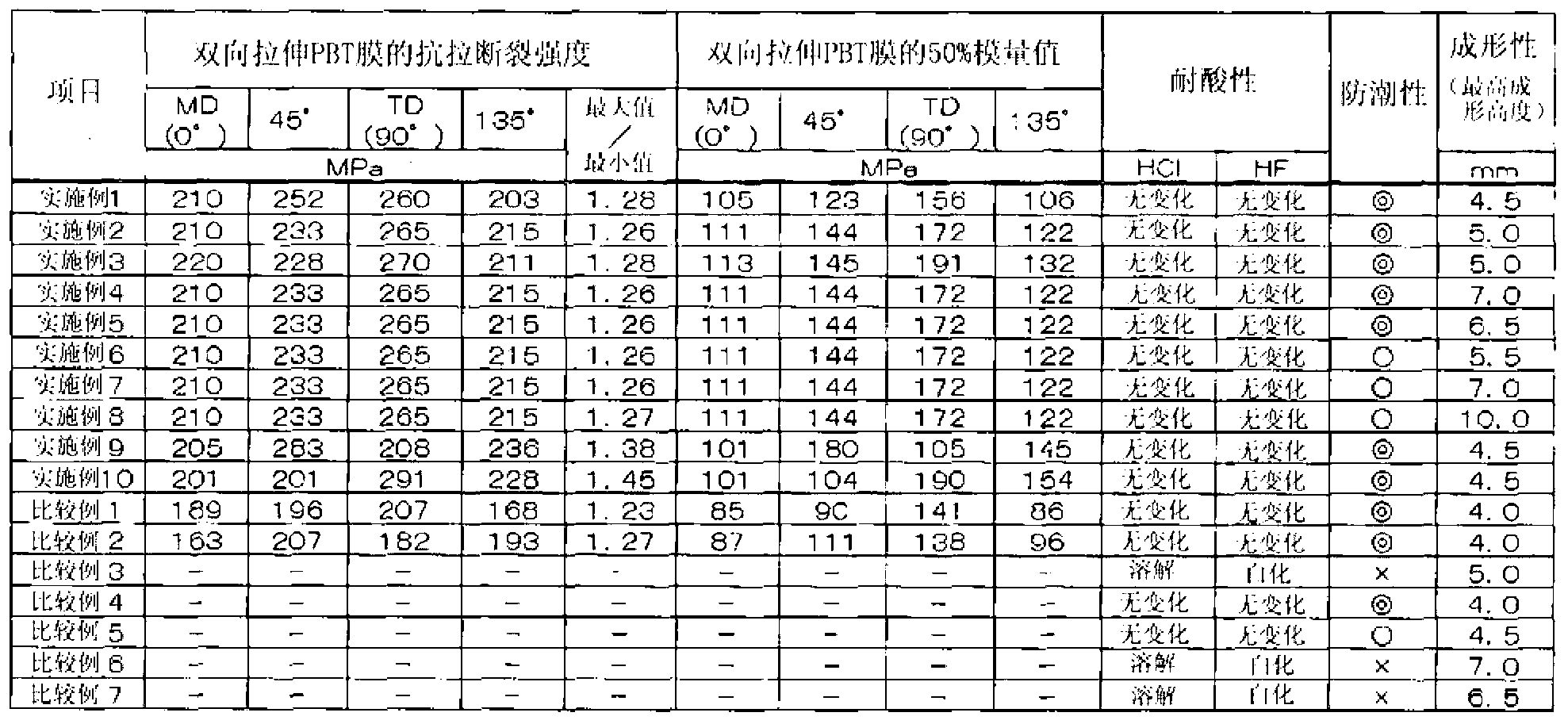

Embodiment 1

[0045] (Manufacturing method of biaxially oriented PBT film)

[0046] Put PBT resin particles (homogeneous type, melting point 224°C, IV value 1.26dl / g) dried at 140°C for 5 hours by a hot air dryer in the extruder, and the cylinder and mold temperature is 210~ Melt and knead at 260°C, and extrude a molten tubular film downward from a ring die. Then, after cooling the outer diameter of the mandrel, the film was stretched at a speed of 1.2 m / min by stretching kneading rolls after being folded by Karabusa rolls. The temperature of the cooling water in direct contact with the molten tubular film was 20° C. on the inside and outside, and the cooling rate of the film before stretching was 416° C. / sec. The unstretched film had a thickness of 130 μm and a folded diameter of 143 mm before stretching, and 1000 ppm of magnesium stearate as a lubricant was previously added to the PBT resin. Under the above-mentioned conditions, the unstretched and stretched film 1 of film formation is ...

Embodiment 2~3、 comparative example 1~2

[0059] Except that the stretch ratio in Example 1 was changed to the conditions recorded in Table 1, the rest were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com