Sewing machine needle

A sewing machine and machine needle technology, applied in the field of sewing machine needles, can solve problems such as large gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preferred embodiment of the present invention will be described with reference to the accompanying drawings.

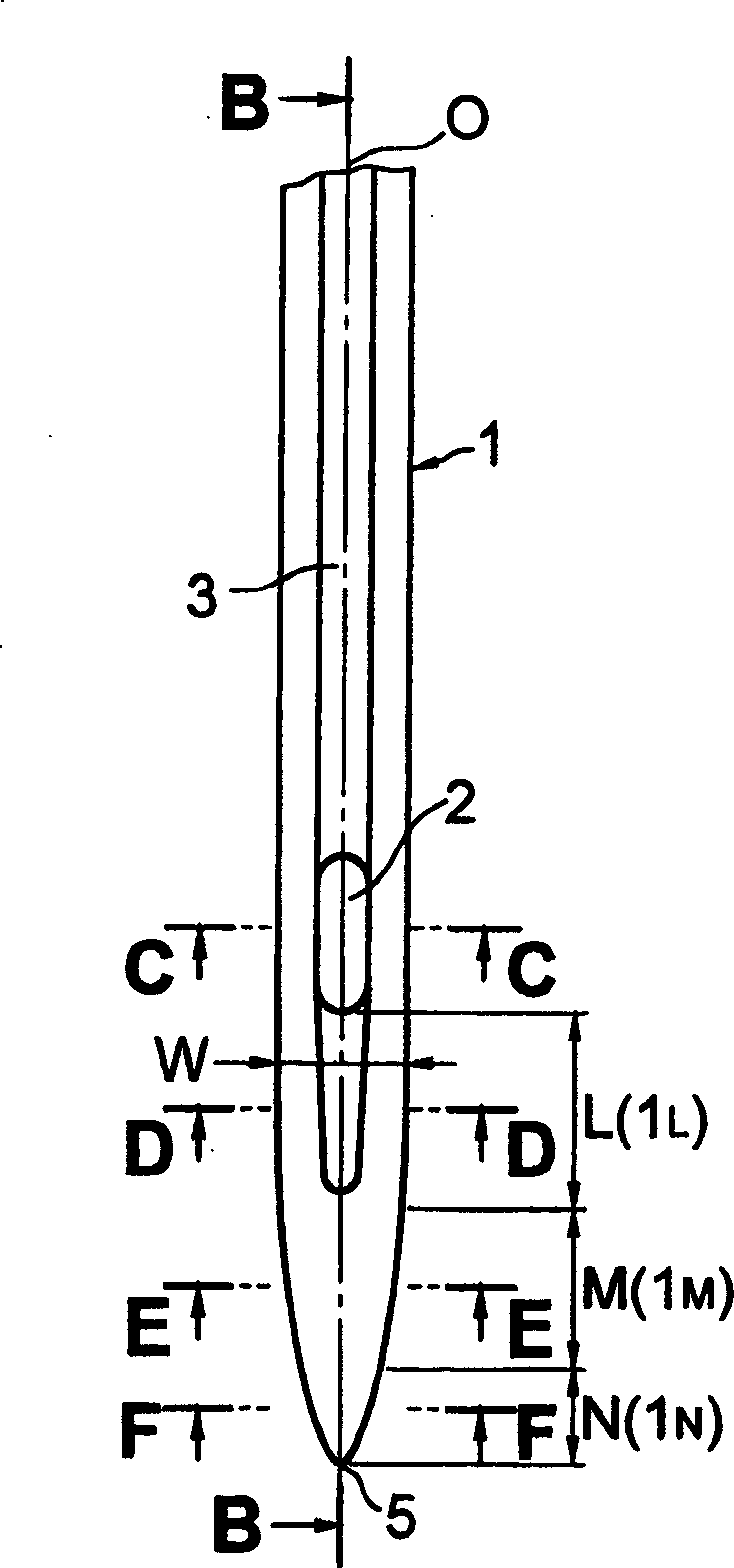

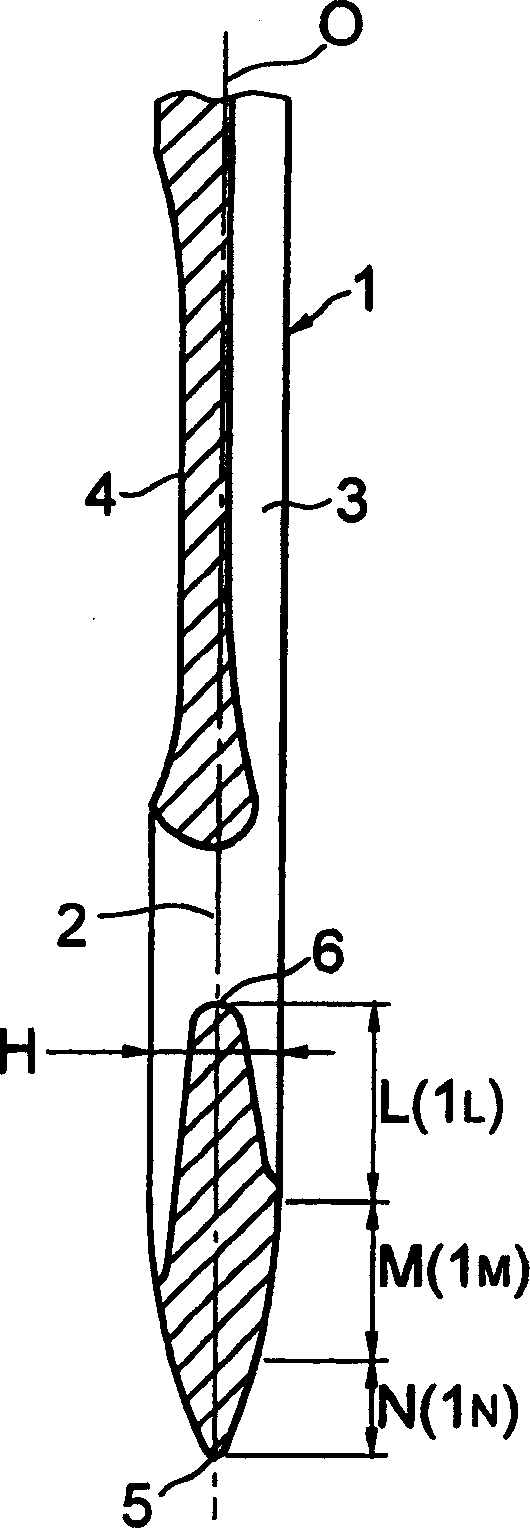

[0020] First refer to Figures 1A-1F , shows an embodiment of the sewing machine needle of the present invention.

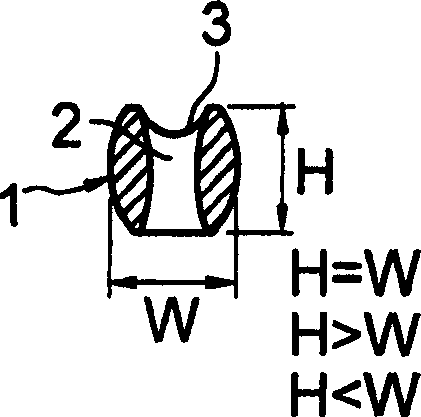

[0021] In the drawings, reference numeral 1 denotes a needle shank, reference numeral 2 denotes a needle eye formed near a needle tip 5 on the distal end portion of the needle shank 1, and reference numeral 3 denotes a front edge along the surface of the needle shank. The long groove formed on the side, reference numeral 4 represents a slope. The sewing machine needle according to the present invention is as Figure 1B As shown, it is configured so that on the predetermined length L of the needle eye 2 from an edge 6 close to the needle tip 5 toward the needle tip 5, when the direction perpendicular to the direction in which the needle eye 2 extends from the side of the needle When viewed from the direction, the needle bar 1 has a straight lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com