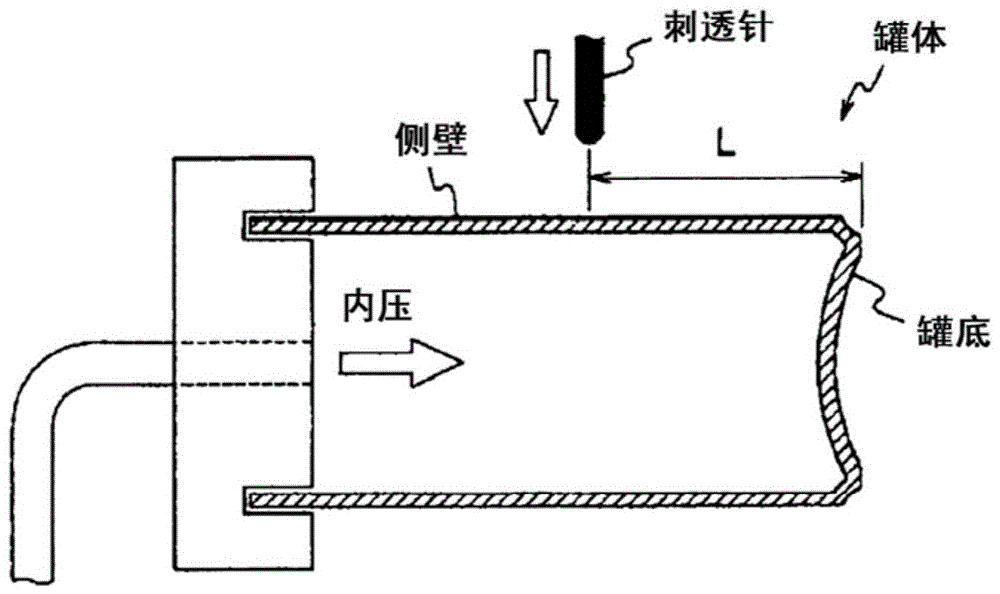

Aluminum alloy plate for di tank body

A technology for aluminum alloy plates and tanks, applied in the field of aluminum alloy plates, can solve problems such as leakage of fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

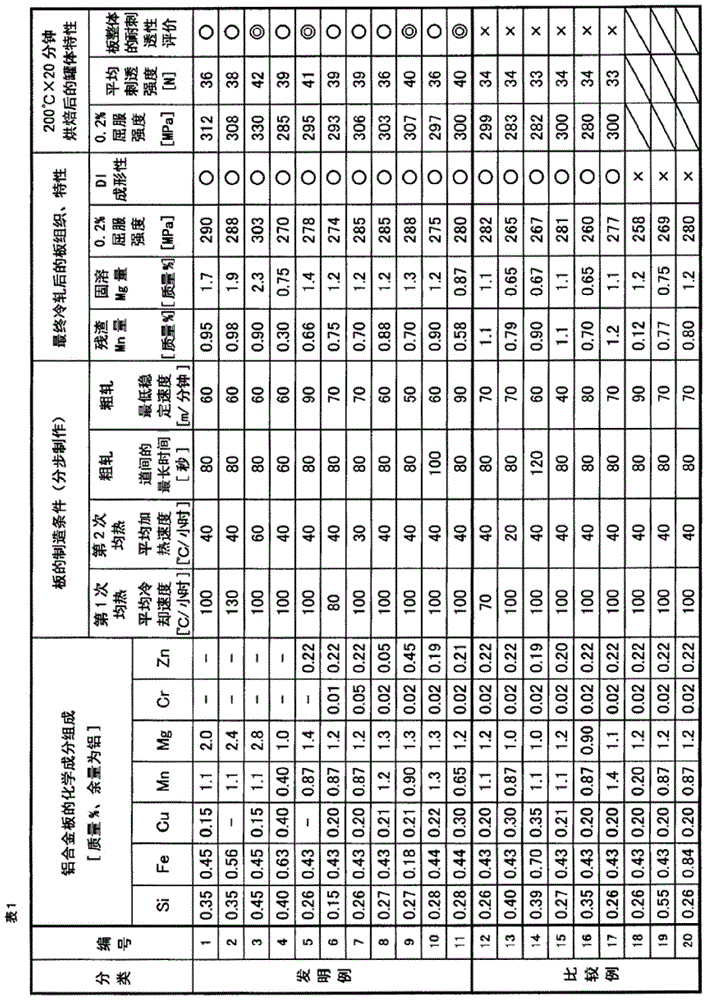

[0095] The mode for carrying out the present invention has been described above, but the following concrete description will be given by comparing Examples in which the effects of the present invention have been confirmed and Comparative Examples not satisfying the requirements of the present invention. In addition, this invention is not limited to this Example.

[0096] (Sample material aluminum alloy plate)

[0097] The aluminum alloys of the compositions shown in Table 1 were melted and semi-continuous casting was used, and ingots were produced in common for each example at the casting rate and cooling rate within the above-mentioned preferable numerical ranges.

[0098] The ingot was subjected to the above-mentioned two soaks, and each case was collectively subjected to the first soak at a soaking temperature of 600°C for 4 hours. The ingot was temporarily cooled to room temperature with various changes as shown in Table 1. Then, as the second soaking, the ingot was rehe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com