Automatic polishing machine for inner circle of long pipe

A technology for automatic polishing and long pipes, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc. Limitation and other issues, to achieve the effect of low energy consumption, good automation and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

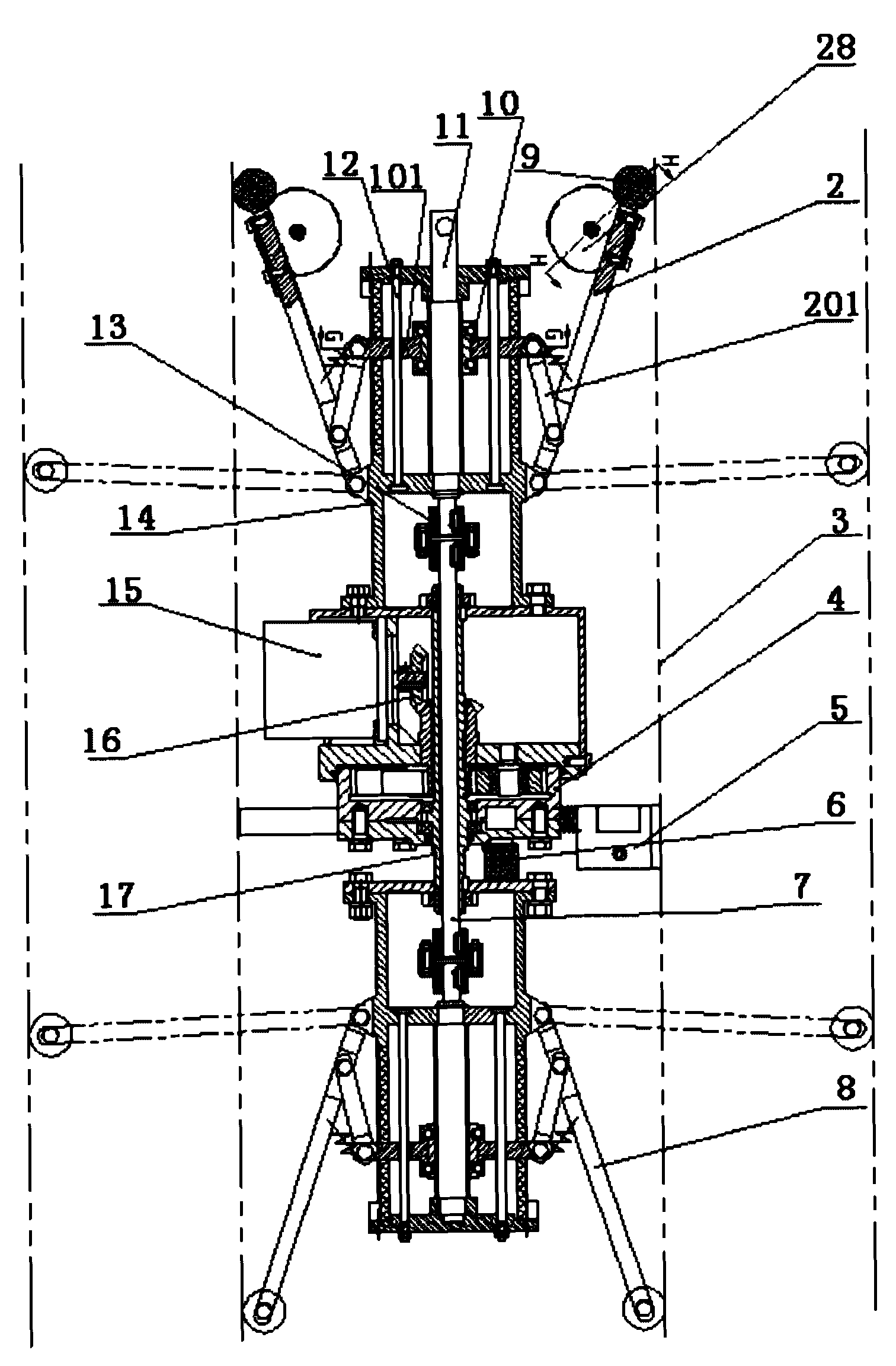

[0022] refer to Figure 1-4

[0023] The long pipe inner circle automatic polishing machine includes a polishing mechanism 5 and a traveling mechanism connected to the same longitudinal main shaft 7, the front and rear ends of the polishing mechanism 5 are respectively connected to a traveling mechanism; the main shaft 7 is provided with a coupling Device 13;

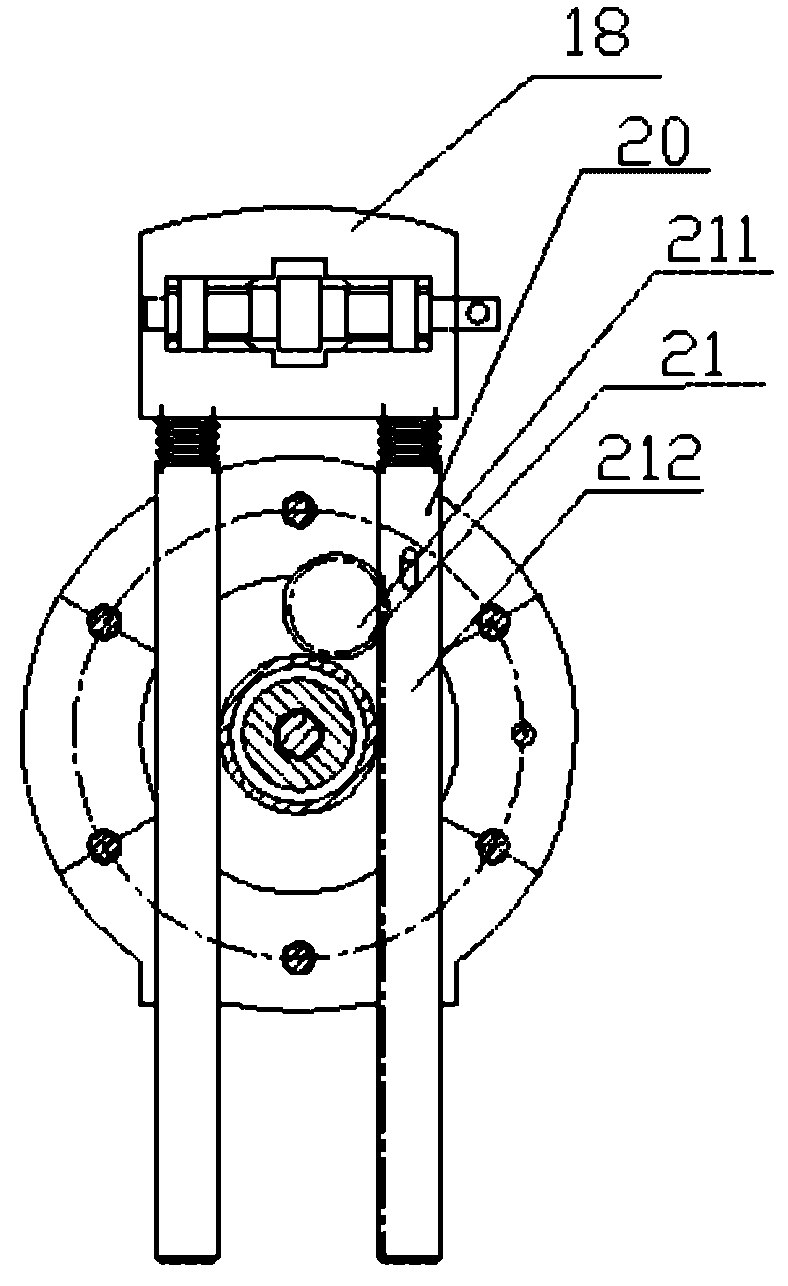

[0024] Described polishing mechanism 5 is made up of circular feed mechanism and polishing chuck 18;

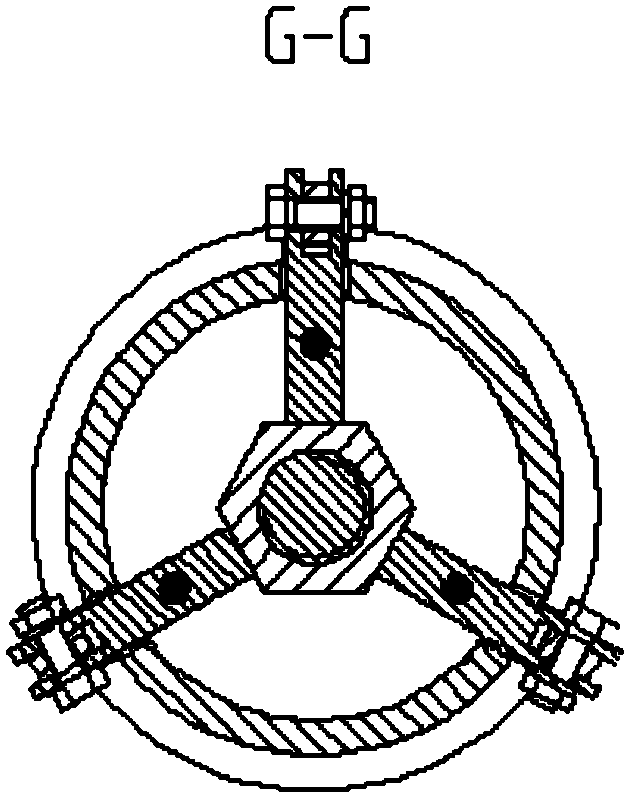

[0025] The circular feed mechanism includes a planetary gear mechanism 4 driven by a first motor 15, and the first motor 15 drives the planetary gear mechanism through a bevel gear mechanism 16, and the planetary gear mechanism 4 is connected through a connecting sleeve 17 so that The main shaft 7 described above is a rotating shaft, and the polishing chuck 18 is arranged on the internal gear of the planetary gear mechanism 4, and the planetary gear mechanism 4 drives the entire polishing chuck 18 to move in a circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com