Belt type carrier-based aircraft booster system and decentralized energy storage and concentrated random boosting working method

A carrier-based aircraft and booster technology, which is applied in the launch/tug transmission device and other directions, can solve the problems of consuming aircraft carrier boilers, uneconomical, large initial energy, etc., and achieves accelerated humanization, space saving, and scientific and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

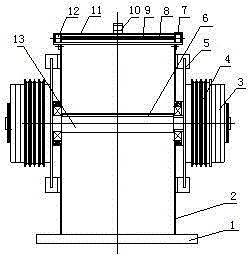

[0073] The design steps are as follows:

[0074] The carrier-based aircraft must obtain 30m / s on a runway of 100m 2 Acceleration can take off, the aircraft takeoff speed and acceleration movement time calculation formula is as follows:

[0075] V=√(2aL)=√(200×30)≈77.46m / s (1)

[0076] t=√(2L / a)=√(200 / 30)≈2.58s (2)

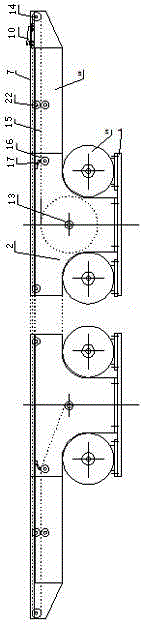

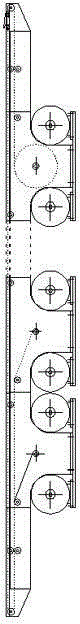

[0077] The length of the drive belt = the length of the runway, L = the sum of the lengths of the drive belts wound on the drive shaft, the length of the drive belt

[0078] L=(L1+L2+…LN)=100m=length of booster runway (3)

[0079] The formula for calculating the length of each layer of drive belt on the drive shaft: Li=3.14(D+2dn) (4)

[0080] D is the diameter of the drive shaft,

[0081] d = thickness of the drive belt;

[0082] n = number of layers of belt

[0083] L=100=3.14[(D+2d1)+(D+2d2)+(D+2d3)+...(D+2dn)] (5)

[0084] The length of the known booster runway = the length of the transmission belt = 100 meters, ignoring the winding density o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com