Rotary niobium oxide target material and preparation method thereof

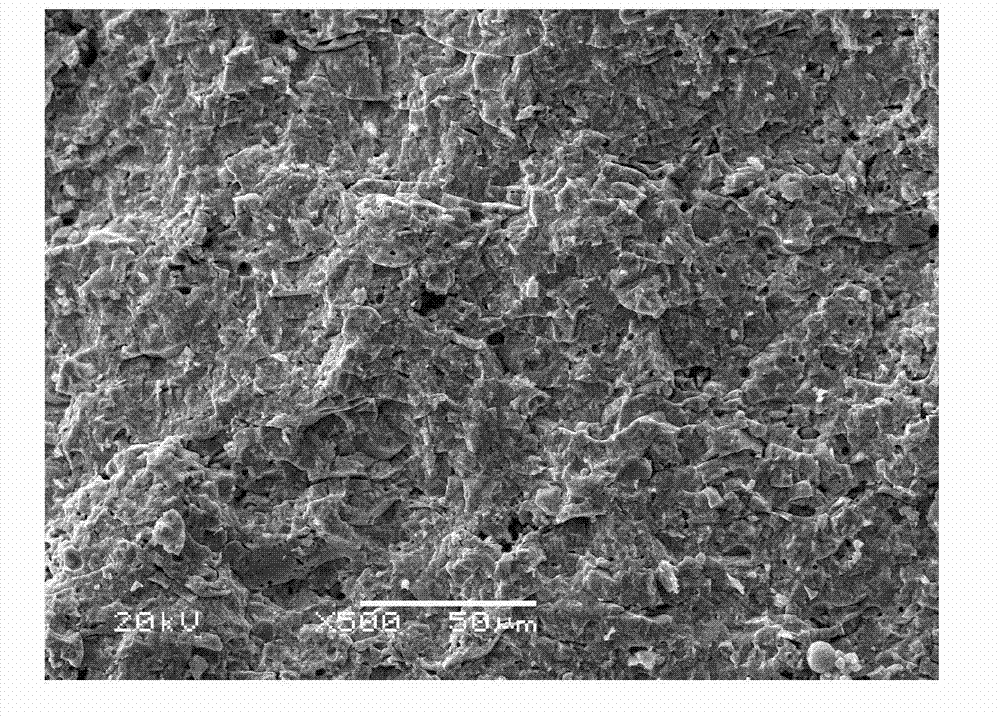

A technology of niobium oxide and rotating target, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve problems not involving niobium oxide rotating target, and achieve simple and convenient production process, uniform composition and structure dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

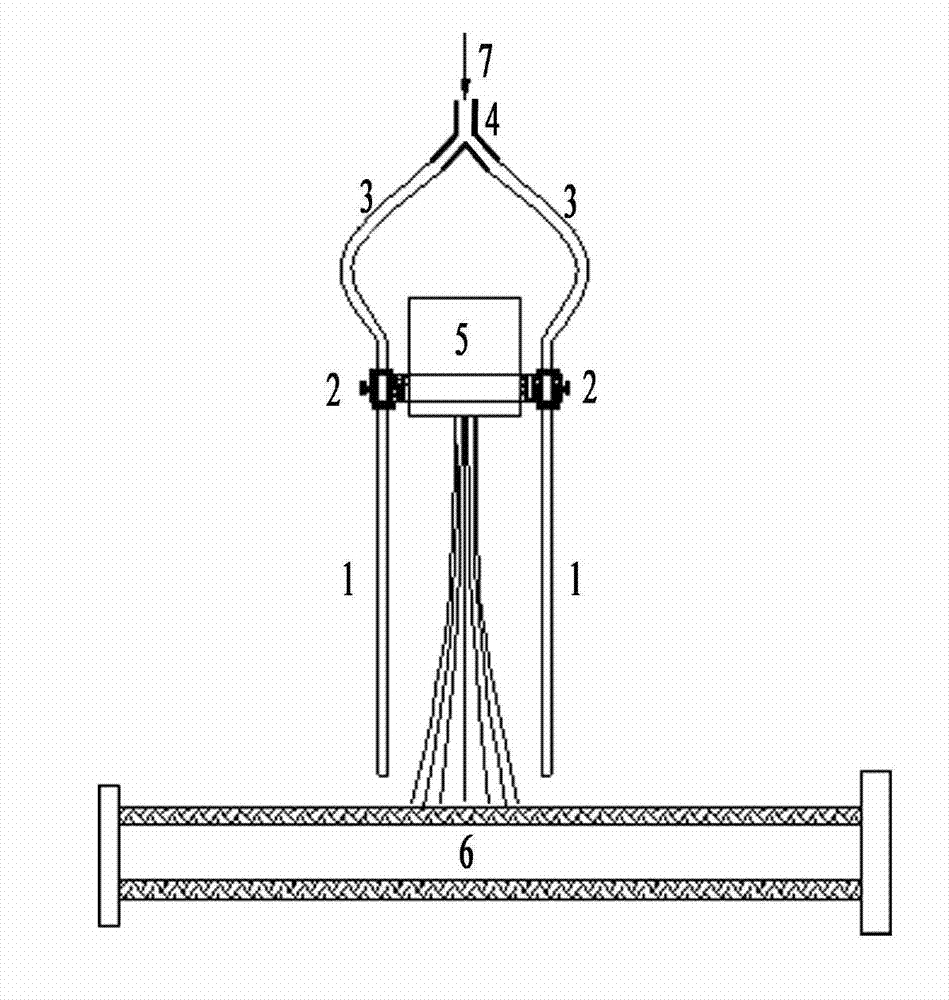

Method used

Image

Examples

Embodiment 1

[0031] A niobium oxide target with a thickness of 5 mm is sprayed on a stainless steel tube with an outer diameter of 66 mm and a length of 100 mm.

[0032] 1. Mix niobium oxide powder with a purity of not less than 99.95wt% and a particle size of about 2 μm with 4% Nb powder by weight, mechanically mix and sinter in vacuum at 1250°C for 8 hours to agglomerate and grow, and then After ball milling and sieving, 150-300 mesh niobium oxide spray powder is obtained.

[0033] 2. Treatment of sprayed substrate: Use cleaning and mechanical grinding to remove surface dirt and oxide layer, and sandblasting to make the surface of the substrate reach a certain roughness.

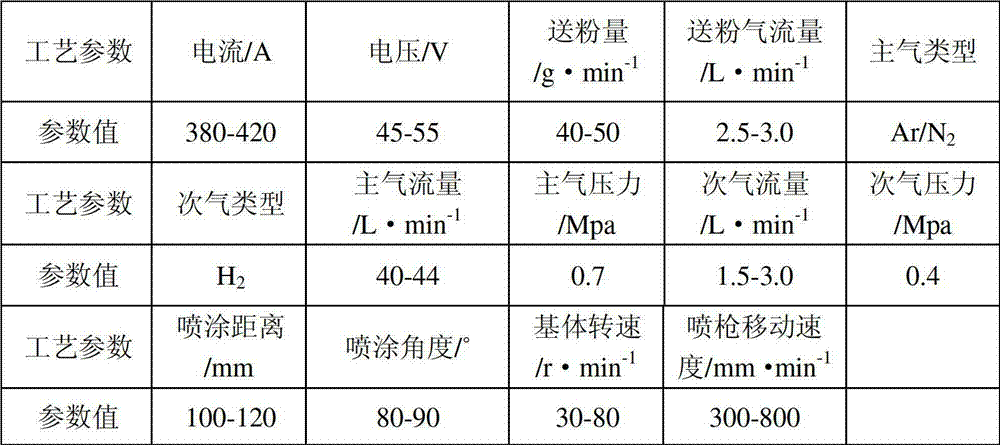

[0034] 3. Spraying base layer: Spray 0.2mm nickel-clad aluminum coating with plasma spraying method. The parameters are shown in Table 3.

[0035] Table 3 Plasma Spraying Nickel-clad Aluminum Primer Parameters

[0036]

[0037] 4. Spray the niobium oxide spray powder on the substrate tube that has been sprayed wi...

Embodiment 2

[0042] A niobium oxide target with a thickness of 10 mm is sprayed on a stainless steel pipe with an outer diameter of 133 mm and a length of 50 mm.

[0043]1. The 4% Nb powder by weight in the niobium oxide powder with a purity of not less than 99.95wt% and a particle size of about 2 μm is mechanically mixed and sintered in vacuum at 1250°C for 8 hours to agglomerate and grow, and then ball milled and sieving to obtain 150-300 mesh niobium oxide spray powder.

[0044] 2. Treatment of the sprayed substrate: Use cleaning and mechanical grinding to remove the surface dirt and oxide layer, and then use sandblasting to roughen the surface of the substrate to make the surface of the substrate reach a certain roughness, so as to increase the bonding strength between the substrate and the coating.

[0045] 3. Spraying base layer: Spray 0.2mm nickel-clad aluminum coating with plasma spraying method. The parameters are shown in Table 3.

[0046] 4. Spray the niobium oxide spray powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com