Linear nano carbon tube composite-field emission source and method for preparing same and dedicated device therefor

A technology of carbon nanotubes and composite fields, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., and can solve the problems of equipment investment cost and power consumption increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

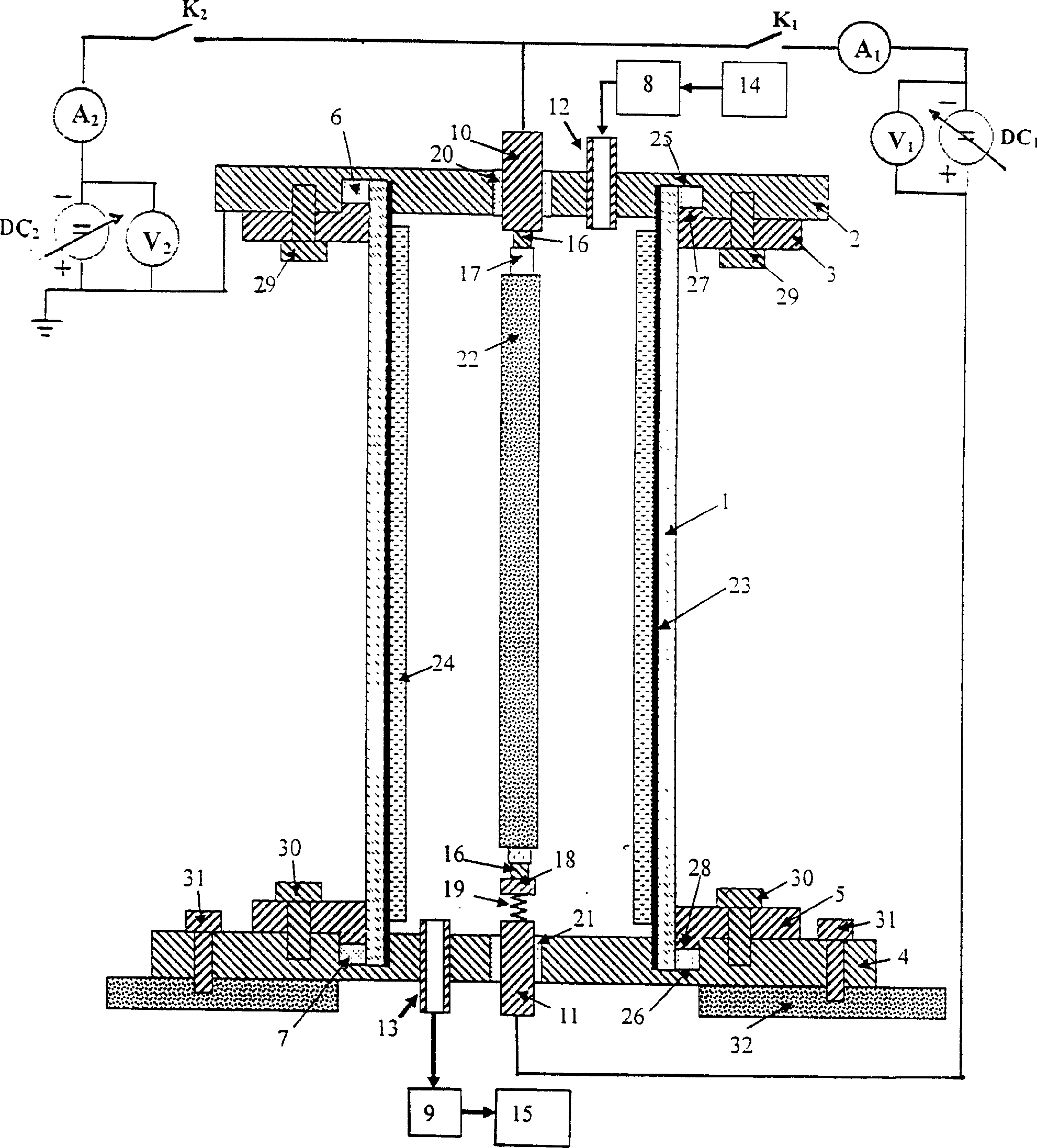

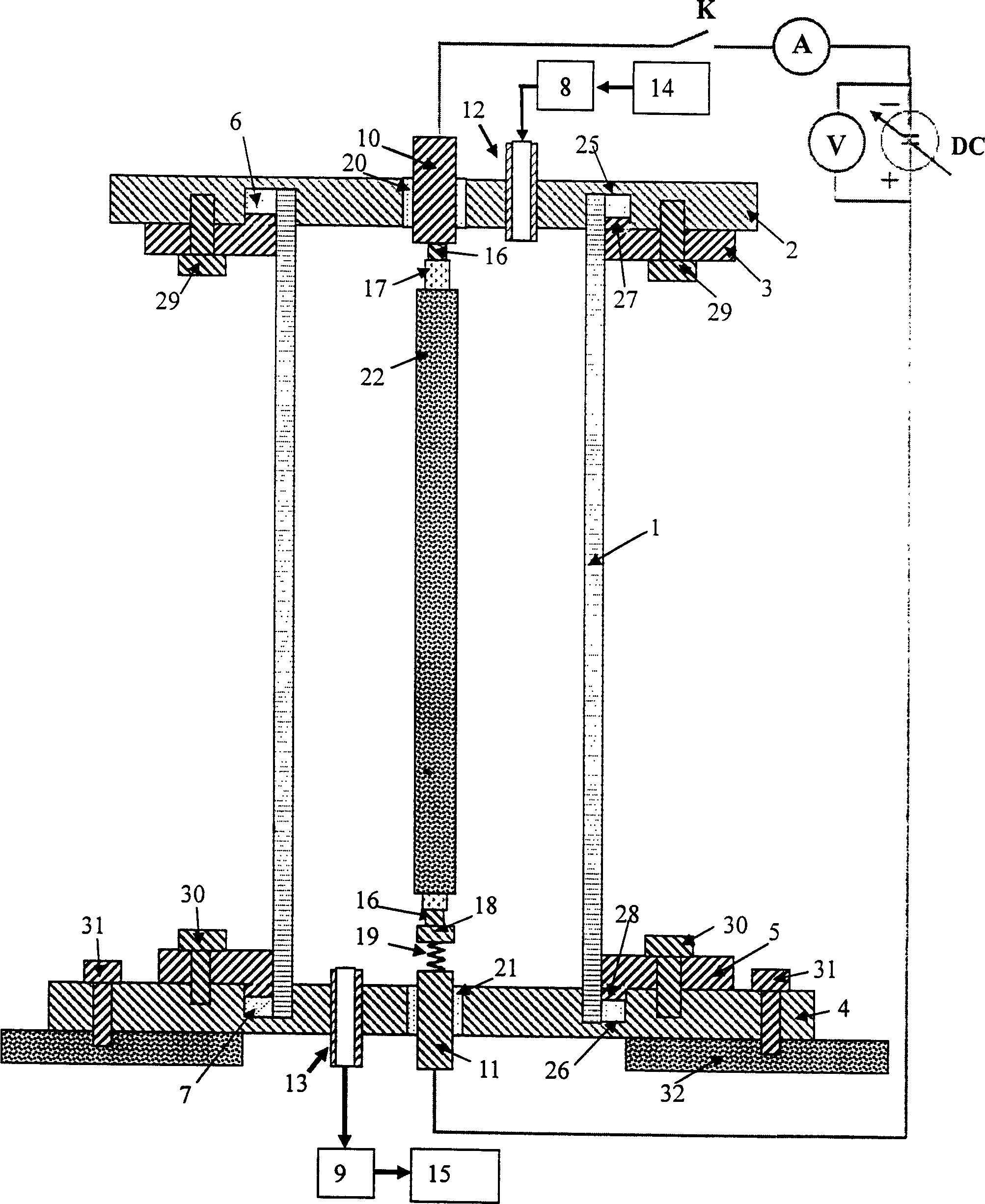

[0063] This embodiment is based on figure 1 The description of the dedicated device for preparing linear CNTs composite field emission source is shown. The device can be used to prepare linear CNTs composite field emission source and test the field emission characteristics and luminescence characteristics of linear CNTs composite field emission source. In order to clearly show the structure of the linear CNTs field emission source, in figure 1 In the middle, the catalyst film 17 and the carbon nanotube film 18 on the fiber braided rope 16 are respectively peeled downward or upward into a small section. figure 1 The device shown is composed of a reaction chamber, a self-powered circuit and a field emission test circuit.

[0064] The reaction chamber is composed of a cylindrical cavity 1, first and second upper covers 2 and 3, first and second lower covers 4 and 5, and a gas path system. The cylindrical cavity 1 is a domestic T-shaped fluorescent lamp glass tube, with a length of...

Embodiment 2

[0075] In the device of this embodiment, the cylindrical cavity 1 uses a domestic T-shaped fluorescent lamp glass tube, which has a diameter of 3 cm, a wall thickness of 1.2 mm, and a length of 30 cm. A 200m thick transparent conductive ITO film was coated on the inner wall of the glass tube by sol-gel extraction method, and a Nichia NP1045 white phosphor layer was deposited on the transparent conductive ITO film by electrophoresis, with a thickness of 20μm. The other parts of the device are the same as in Example 1.

[0076] The steps of making linear CNTs composite field emission source are as follows:

[0077] (1) Selection and treatment of fiber braided rope: select a Fe-Al-Cr alloy fiber braided rope (fiber diameter of 1μm) with a length of 30cm and a diameter of 0.5mm as the substrate material, and the Fe-Al- The Cr alloy fiber braided rope is sequentially placed in acetone and ethanol for ultrasonic cleaning, and then oxidized in the air at 1000°C for 12 hours to form a den...

Embodiment 3

[0085] In the device of this embodiment, the cylindrical cavity 1 uses a domestic T-shaped fluorescent lamp glass tube, which has a diameter of 4 cm, a wall thickness of 1.4 mm, and a length of 50 cm. A sol-gel extraction method is used to coat a 250nm thick transparent conductive ITO film on the inner wall of the glass tube. Electrophoresis is used to deposit a 30μm-thick phosphor layer on the transparent conductive ITO film. The phosphor is a German Osram-P22 type green phosphor. The other parts of the device are the same as in Example 1.

[0086] The following describes the steps of making a linear CNTs composite field emission source using this embodiment:

[0087](1) Selection of fiber braided rope and its treatment: choose Fe-Al-Cr alloy fiber braided rope with a length of 50cm and a diameter of 1.0mm (fiber diameter of 2μm) as the substrate material, and follow the method described in Example 2. Fe-Al-Cr alloy fiber braided rope is cleaned and oxidized.

[0088] (2) Catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com