Carbonitride field emission cathode preparation method

A field emission cathode and titanium sheet technology, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of limited growth area and complex growth process of carbon nitride nanotube film, and achieve key Good combination, excellent field emission characteristics, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

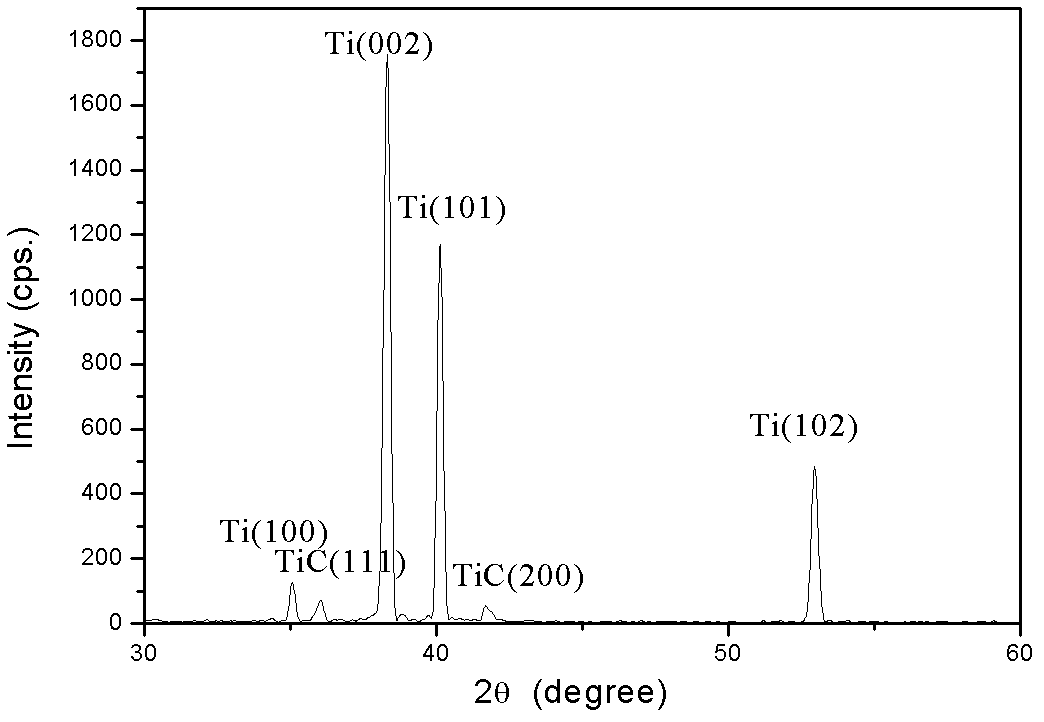

[0027] According to the technical solution of the present invention, the present embodiment provides a method for preparing a CNx field emission cathode, which specifically includes the following steps:

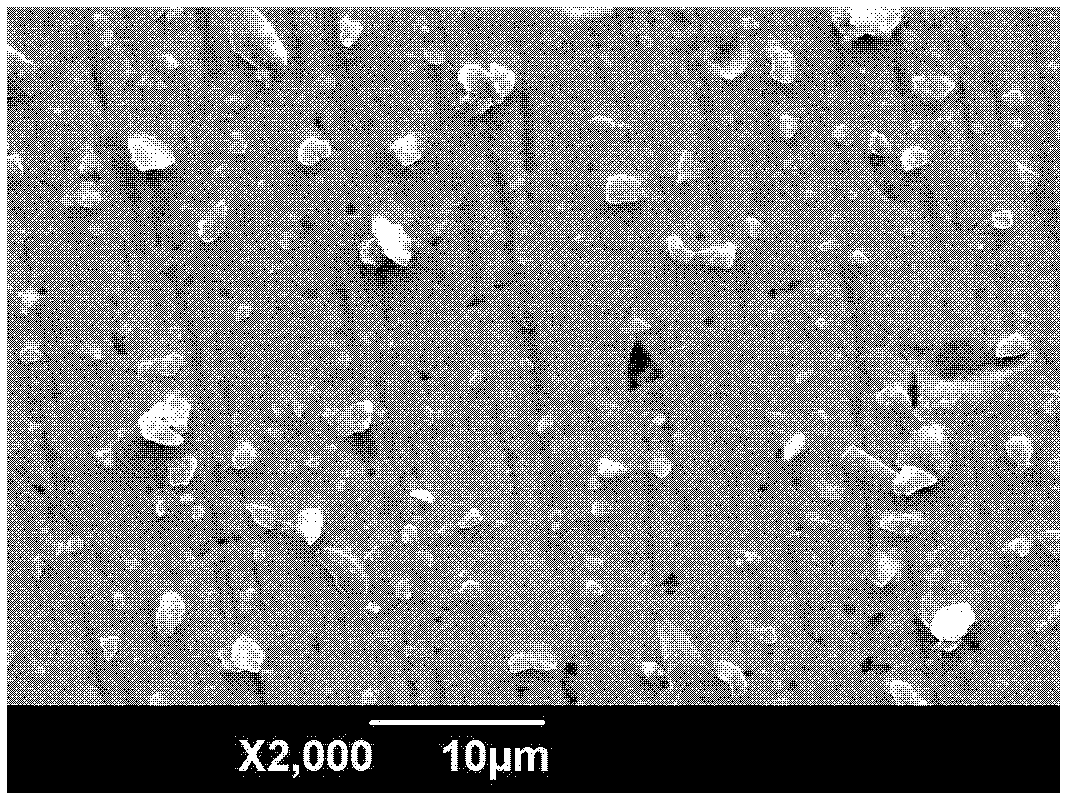

[0028] 1) Select a titanium sheet as the substrate, grind and polish one surface of the titanium sheet, place it in acetone for ultrasonic cleaning, then rinse with deionized water and dehydrate with ethanol;

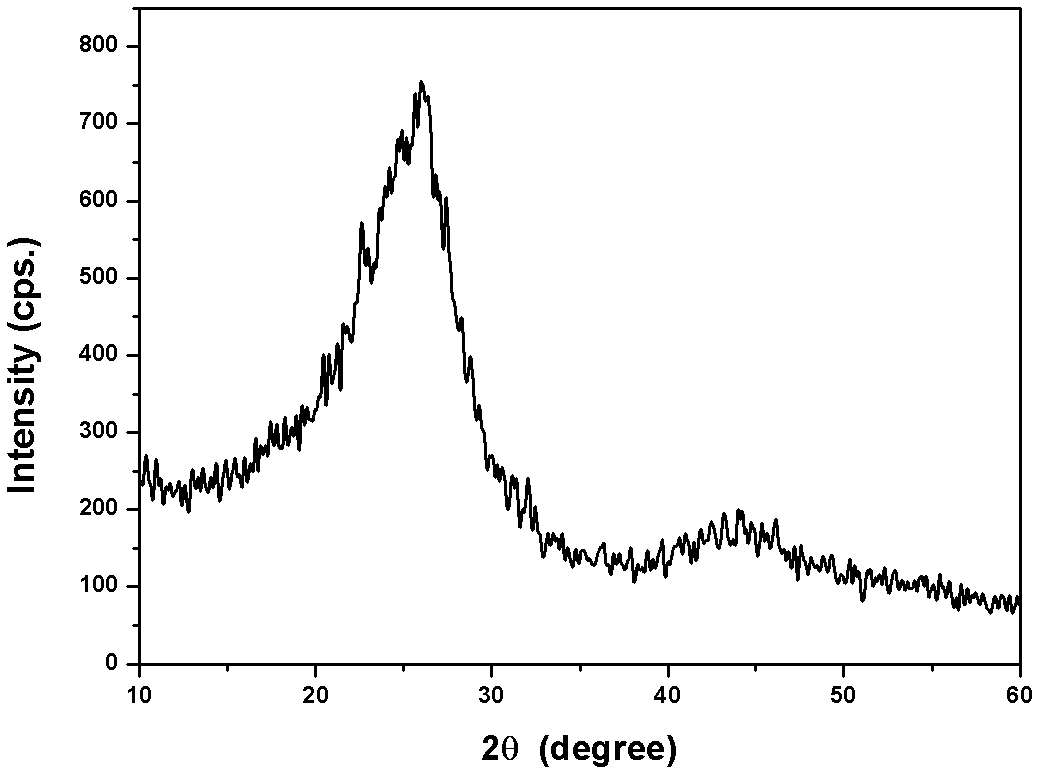

[0029] 2) Select the graphite-like phase CNx particles prepared by the sol-gel method known in the art as the field emitter material, and grind the graphite-like phase CNx particles to the order of several microns;

[0030] 3) Preparation of CNx suspension: the solute is selected from graphite-like phase CNx particles after grinding; the solvent is selected from acetone; the adhesive is polyvinyl acetate, which is dissolved in acetone to prepare a 10% colloid solution; the solute, The solvent and the colloidal solution are mixed and stirred evenly to make a CNx suspens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com