GaN microrod array/graphene field emission cathode composite material preparation method

A technology of emitting cathode and composite material, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problem of current uniformity and stability to be improved, difficulty in large current emission, and small electron affinity. and other problems, to achieve the effect of good field emission stability, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

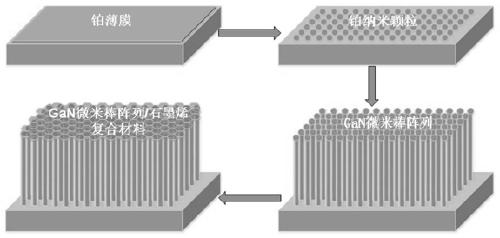

[0025] The invention provides a GaN microrod array / graphene field emission cathode composite material preparation method, the specific steps are as follows:

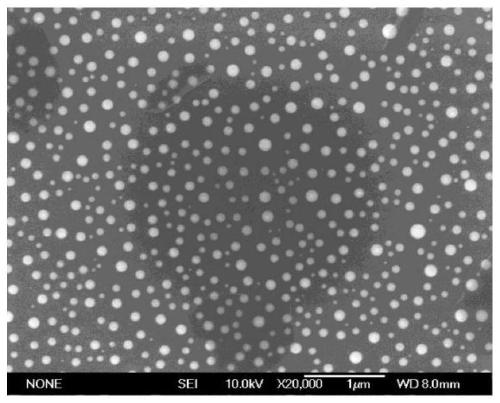

[0026] Step 1, using the JFC-1600 ion sputtering coater, the vacuum degree is 8×10 -3 In the case of Pa, set the sputtering current to 40-60mA, and the sputtering time to 40-80s, coat the silicon substrate with a platinum film, put the silicon substrate sputtered with a platinum film into a quartz boat, with the coating surface facing up, Then push the quartz boat into the constant temperature zone of the tube furnace and anneal the silicon substrate. Nitrogen was used to remove the air in the furnace tube for 20 minutes, and then the temperature was raised to 800-1200°C at a rate of 10°C per minute for annealing treatment, and naturally cooled to room temperature after annealing. Obtain substrate A;

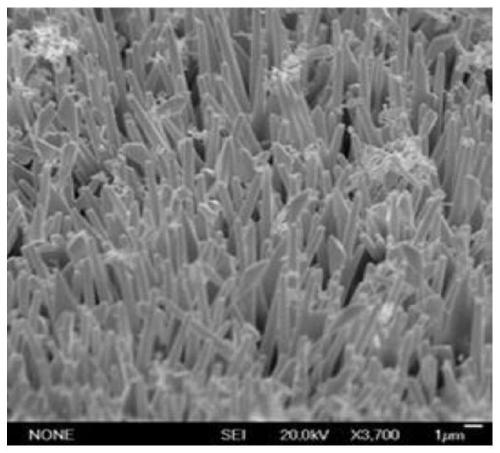

[0027] Step 2, move the substrate A obtained in step 1 into the quartz boat, use ammonia gas and gallium oxide as the ...

Embodiment 1

[0033] A GaN microrod array / graphene field emission cathode composite material preparation method, the specific steps are as follows:

[0034] Step 1, using the JFC-1600 ion sputtering coater, the vacuum degree is 8×10 -3 In the case of Pa, set the sputtering current to 40mA and the sputtering time to 40s, and coat the silicon substrate with a platinum film. Push it into the constant temperature zone of the tube furnace to anneal the silicon substrate. Set the annealing temperature to 800°C, the flow rate of ammonia gas to 50 sccm, and the annealing time to 5 minutes. , and then heat up to 800°C at a rate of 10°C per minute for annealing, and naturally cool to room temperature after annealing to obtain a substrate A;

[0035] Step 2, move the substrate A obtained in step 1 into the quartz boat, use ammonia gas and gallium oxide as the nitrogen source and gallium source, first place the carbon powder and gallium oxide in the quartz boat at a ratio of 1:1, and then place the su...

Embodiment 2

[0038] A GaN microrod array / graphene field emission cathode composite material preparation method, the specific steps are as follows:

[0039] Step 1, using the JFC-1600 ion sputtering coater, the vacuum degree is 8×10 -3 In the case of Pa, set the sputtering current to 60mA and the sputtering time to 80s, coat the silicon substrate with a platinum thin film, put the silicon substrate sputtered with a platinum thin film into a quartz boat with the coated surface facing up, and then put the quartz boat Push it into the constant temperature zone of the tube furnace to anneal the silicon substrate. Set the annealing temperature to 1200°C, the flow rate of ammonia gas to 200 sccm, and the annealing time to 30 minutes. , and then heat up to 1200°C at a rate of 10°C per minute for annealing, and naturally cool to room temperature after annealing. Obtain substrate A;

[0040] Step 2, move the substrate A obtained in step 1 into the quartz boat, use ammonia gas and gallium oxide as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com