Preparation method of large surface area carbon nano pipe film for field emitting display cathode

A carbon nanotube film, carbon nanotube technology, applied in semiconductor devices, electroluminescent light sources, electrical components, etc., can solve the problems of limited and uniform substrate materials, equipment investment and product manufacturing costs, and achieve good alignment. , Large area uniformity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

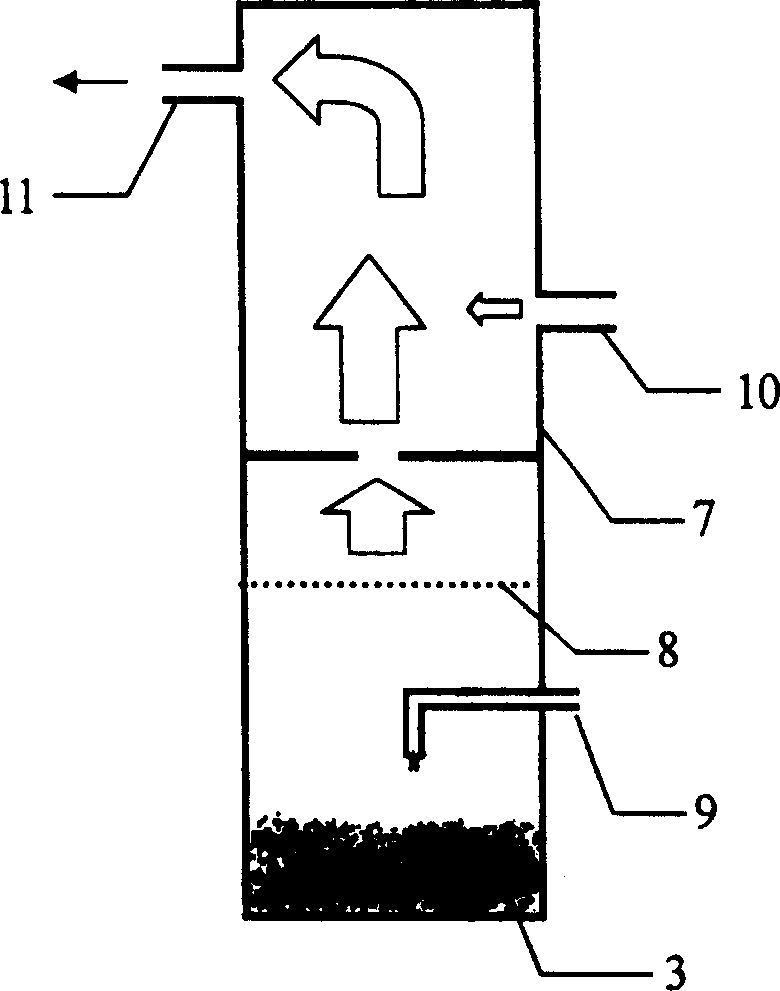

[0032] Since the catalyst used in the preparation process of carbon nanotubes will exist in carbon nanotubes, it should be removed during use. The specific process is to use concentrated nitric acid to dissolve the catalyst present in the carbon nanotubes in the preparation process of the carbon nanotubes; wash with distilled water to neutrality and then fully dry, and then use a ball mill to fully grind in a dry environment to reduce larger agglomerated particles;

[0033] (3) Formation of cathode conductive pattern

[0034] The required cathode pattern can be obtained by performing photolithography and etching on the conductive layer by common photolithography process. For substrate materials without a conductive layer on the surface, the required pattern can be obtained by plate making and printing.

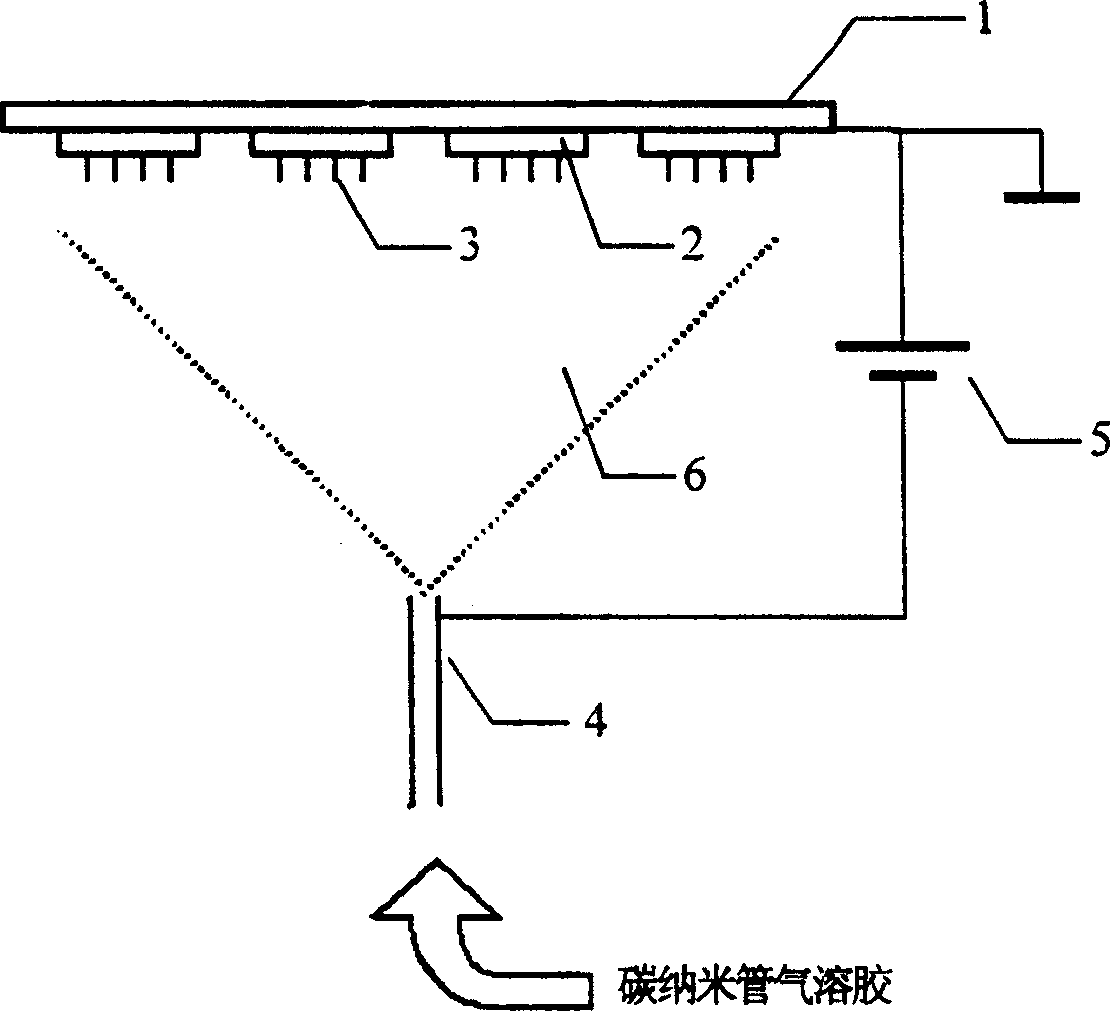

[0036] The adhesive can be coated on the cathode conductive pattern by screen printing or electrostatic spraying. The layout of the screen pla...

Embodiment 1

[0051] Embodiment 1: manufacture has the parallel strip cathode of the small field emission flat panel display of X-Y addressing

[0052] Its manufacturing process is as follows:

[0053] 1. Substrate selection and pretreatment

[0054] In this embodiment, glass with an ITO conductive layer (hereinafter referred to as ITO glass) is used as the substrate. Put the selected glass into a cleaning solution mixed with absolute alcohol and acetone at a volume ratio of 1:1, perform ultrasonic cleaning for 15 minutes, then ultrasonically clean it with deionized water for 15 minutes, and dry it in a clean environment. Dry and set aside.

[0055] 2. Pretreatment of carbon nanotubes

[0056] The carbon nanotubes used in this embodiment are multi-walled carbon nanotubes prepared by CVD, which contain a lot of impurities mainly including catalyst particles (mainly iron and its oxides). Its pretreatment is mainly to remove these impurities therein, and then make carbon nanotube powder wi...

Embodiment 2

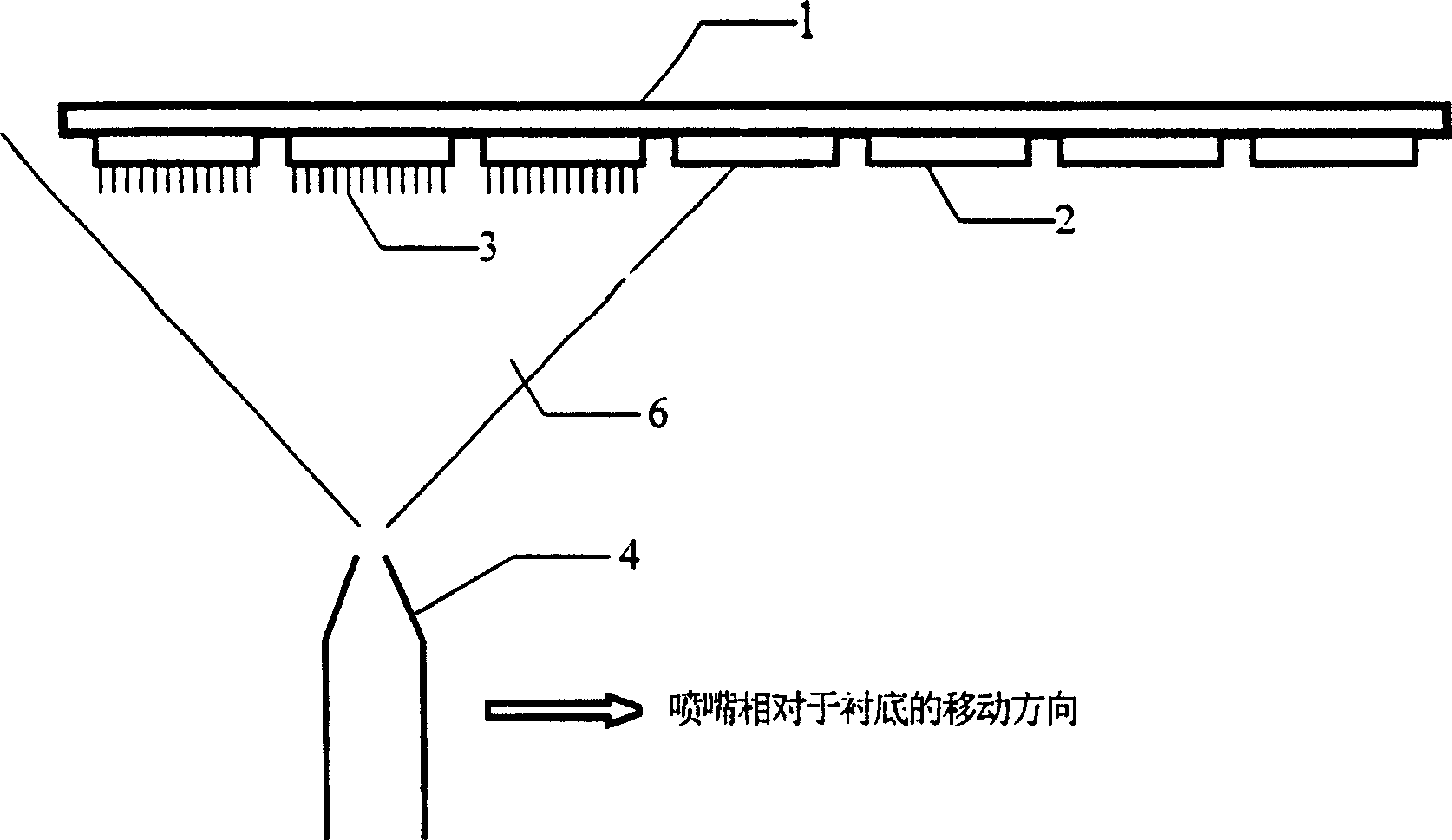

[0067] Embodiment 2: manufacture the parallel strip cathode of the elongated field emission flat panel display with X-Y addressing

[0068] The manufacturing process of this embodiment is the same as that of Embodiment 1, except that a moving nozzle system is used in step 5. Of course, the preparation can also be completed by spraying with nozzle arrays.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com