A kind of comb structure basic anion exchange membrane and its preparation method

A basic anion, comb structure technology, applied in the field of basic anion exchange membrane and its preparation, comb structure basic anion exchange membrane and its preparation, can solve the problem of poor film-forming properties, barriers, low ion conductivity, etc. problem, to achieve good thermal stability, easy to large area, uniform surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

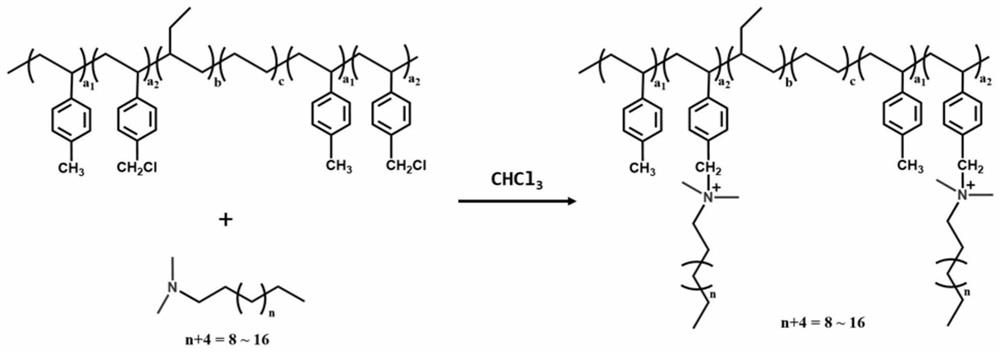

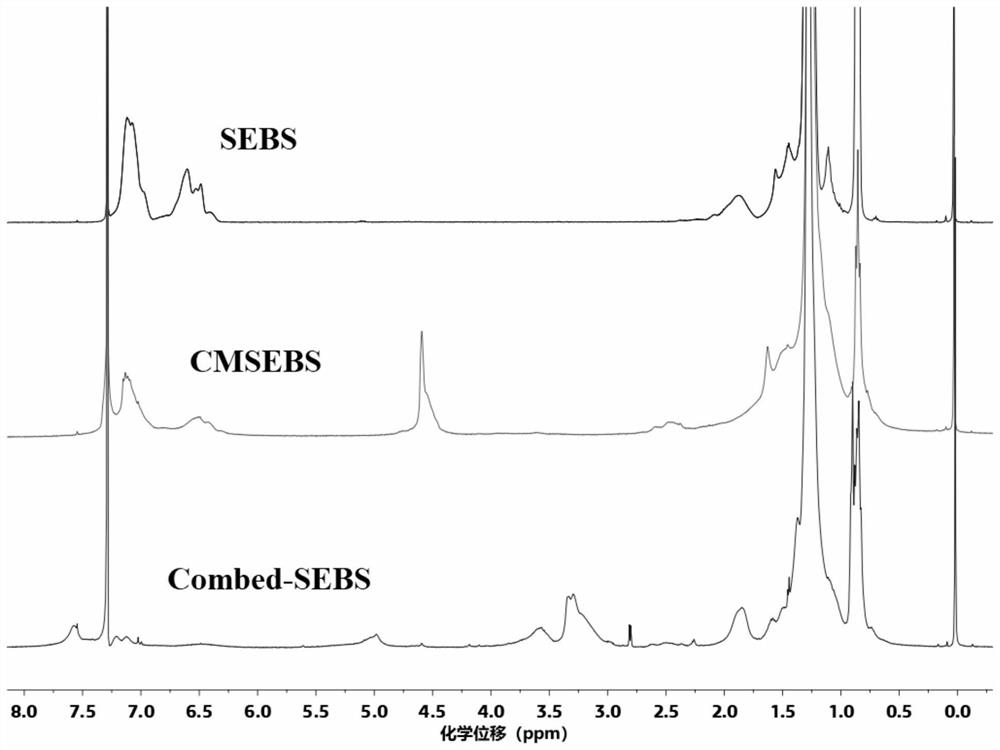

[0052] (1) Preparation of chloromethylated polymer:

[0053] In the hydrogenated styrene-butadiene block copolymer solution, add chloromethylation reagent and catalyst anhydrous tin tetrachloride to carry out chloromethylation reaction, after the reaction finishes, in methanol, ethanol or ethyl acetate solvent Precipitate to obtain chloromethylated hydrogenated styrene-butadiene block copolymer;

[0054] (2) Preparation of comb structure hydrogenated styrene styrene-butadiene block copolymer solution:

[0055] The chloromethylated hydrogenated styrene-butadiene block copolymer obtained in step (1) is dissolved in chloroform, dichloroethane or toluene solvent, and in the resulting solution, add Tertiary amine is reacted to obtain a comb structure hydrogenated styrene styrene-butadiene block copolymer solution;

[0056] (3) Preparation of basic anion exchange membrane:

[0057] The hydrogenated styrene styrene-butadiene block copolymer solution with a comb structure obtained ...

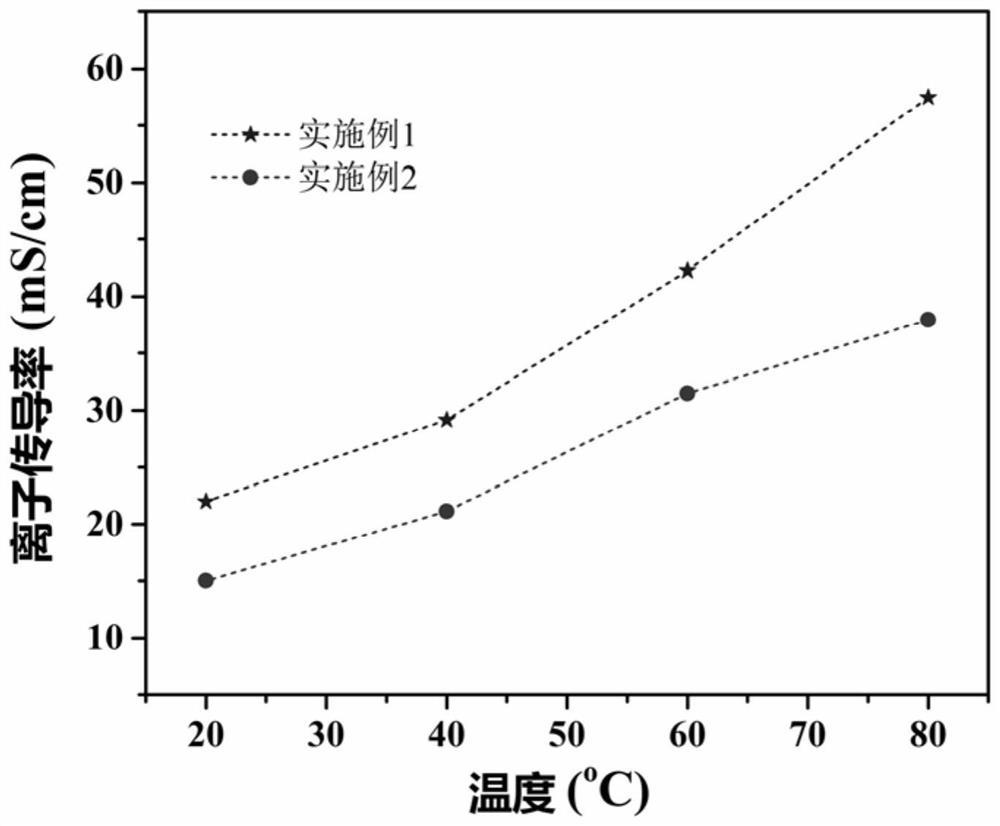

Embodiment 1

[0059] (1) Chloromethylation

[0060] Dissolve 3.0 g of a hydrogenated styrene-butadiene block copolymer (Kraton, A1535) with a molecular weight of about 70,000 and a styrene content of 58 wt% in 90 mL of commercially available chloroform, and use Add 13.8mL of commercially available 1,4-dichloromethoxybutane and 2.1mL of commercially available anhydrous tin tetrachloride dropwise into the dropping funnel. After the dropwise addition, heat the oil bath to 55°C, keep the temperature, and stir Reacted for 3 hours; after the reaction, the reaction solution was lowered to room temperature, poured into 300mL of absolute ethanol, and a lavender solid was precipitated, dissolved in tetrahydrofuran and precipitated with ethanol, and the operation was repeated three times, the solid turned white, and then, Place the white solid at room temperature and dry it under vacuum for 24 hours to obtain chloromethylated hydrogenated styrene styrene-butadiene block copolymer;

[0061] (2) Prepar...

Embodiment 2

[0071] (1) Chloromethylation

[0072] Dissolve 5.0 g of a hydrogenated styrene-butadiene block copolymer with a molecular weight of about 72,000 and a styrene content of 30 wt% (Kraton, G1652) in 150 mL of commercially available chloroform, mechanically stirring, and place on ice. Slowly add 5.4g of commercially available trioxane and 22.8mL of commercially available trimethylchlorosilane dropwise in a water bath. After completely dissolving, add 4.0mL of commercially available anhydrous tin tetrachloride. , kept at 0°C, stirred and reacted for 30 minutes, then raised the temperature to room temperature, kept the temperature, stirred and reacted for 2 hours, after the reaction was completed, the reaction solution was returned to room temperature, poured into 500 mL of commercially available absolute ethanol to precipitate a pale pink solid , dissolve the solid in tetrahydrofuran and precipitate it with ethanol, repeat the operation three times, the solid turns white, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com