Thin film solar cell based on patterned metal substrate and manufacturing method thereof

A technology of thin-film solar cells and metal substrates, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of inability to manufacture thin-film solar cells at low cost, and achieve enhanced light absorption efficiency, improved light absorption efficiency, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Such as Figure 1a to Figure 2d As shown, the present invention provides a kind of fabrication method based on the patterned metal substrate thin-film solar cell, and described fabrication method comprises at least:

[0070] First perform step 1), such as Figures 1a to 1h As shown, a substrate 1 of a first metal material is provided, and a nanoscale pattern structure is produced on the surface of the metal substrate 1 by anodic oxidation or nanoimprinting to form a patterned metal substrate 1, wherein the The first metal material includes at least any one of titanium, aluminum, stainless steel, and copper, or an alloy of any of several.

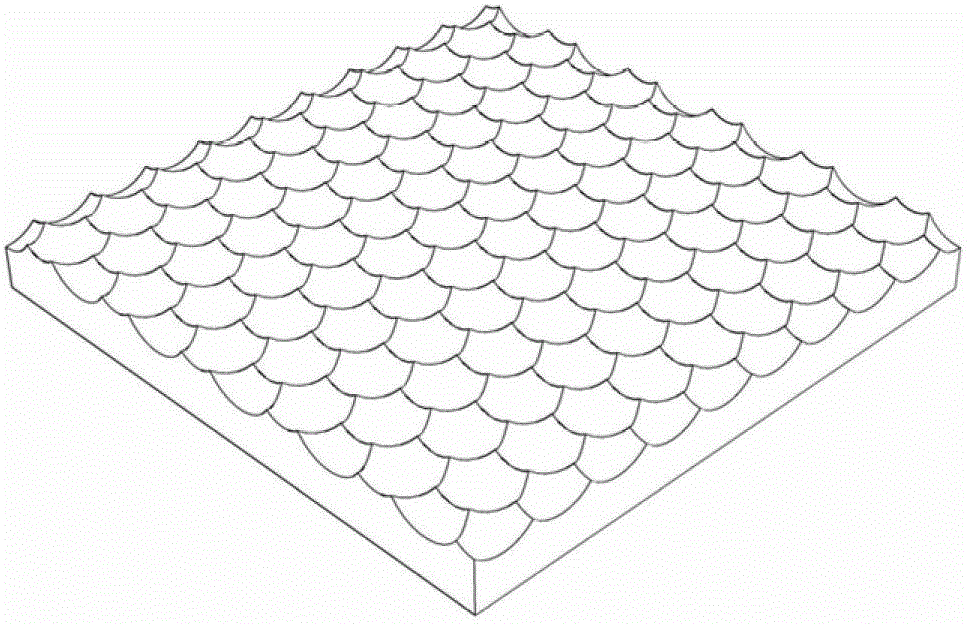

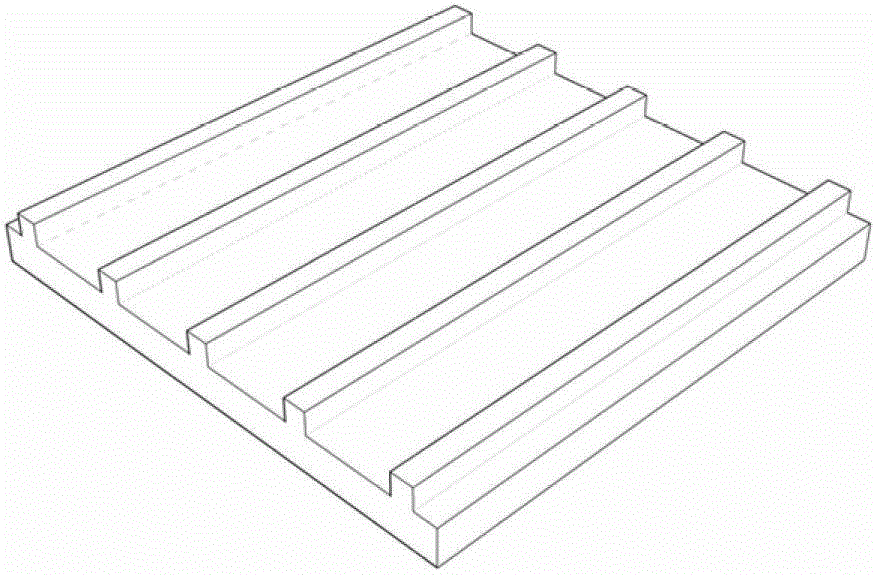

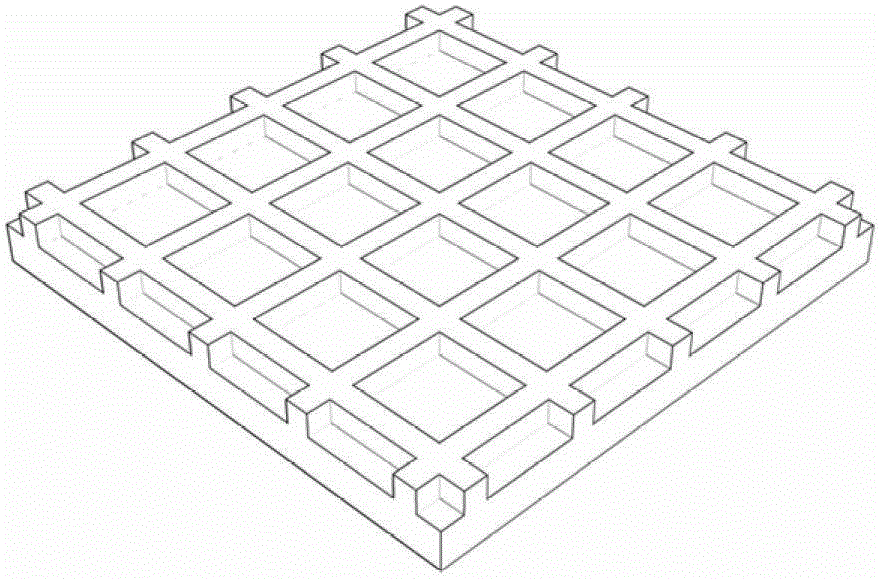

[0071] The nanoscale graphic structure is a disordered or ordered nanoscale graphic structure with a characteristic size ranging from 10 to 1000 nm. As shown in Figure 1, the ordered nanoscale graphic structure at least includes a nanoscale periodic graphic structure, Among them, the nanoscale periodic pattern structure shown in Fig...

Embodiment 2

[0092] The second embodiment uses basically the same manufacturing steps as the first embodiment, the difference is that in the second embodiment, the cadmium telluride thin-film solar cell with a patterned (aluminum) metal substrate is used as an example to illustrate, the following mainly The contents that are different from those in the specific steps of the first embodiment are described.

[0093] Such as Figure 3a to Figure 3c As shown, the present invention provides a kind of fabrication method based on the patterned metal substrate thin-film solar cell, and described fabrication method comprises at least:

[0094] First, perform the step 1) similar to that of Embodiment 1, provide a substrate 1 of a first metal material, and use anodic oxidation or nanoimprinting on the surface of the metal substrate 1 to produce a nanoscale pattern structure to form a pattern Metal Substrate 1.

[0095] Specifically, in the second embodiment, such as Figure 3a As shown, the first ...

Embodiment 3

[0108] The third embodiment adopts basically the same manufacturing steps as the first embodiment, the difference is that in the third embodiment, a copper indium gallium selenide (CIGS) thin film solar cell with a patterned (aluminum) metal substrate is taken as an example. To elaborate, the following mainly elaborates the contents that are different from those in the specific steps of Embodiment 1.

[0109] Such as Figure 4a to Figure 4c As shown, the present invention provides a kind of fabrication method based on the patterned metal substrate thin-film solar cell, and described fabrication method comprises at least:

[0110] First, perform the step 1) similar to that of Embodiment 1, provide a substrate 1 of a first metal material, and use anodic oxidation or nanoimprinting on the surface of the metal substrate 1 to produce a nanoscale pattern structure to form a pattern Metal Substrate 1.

[0111] Specifically, in the third embodiment, such as Figure 4a As shown, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com