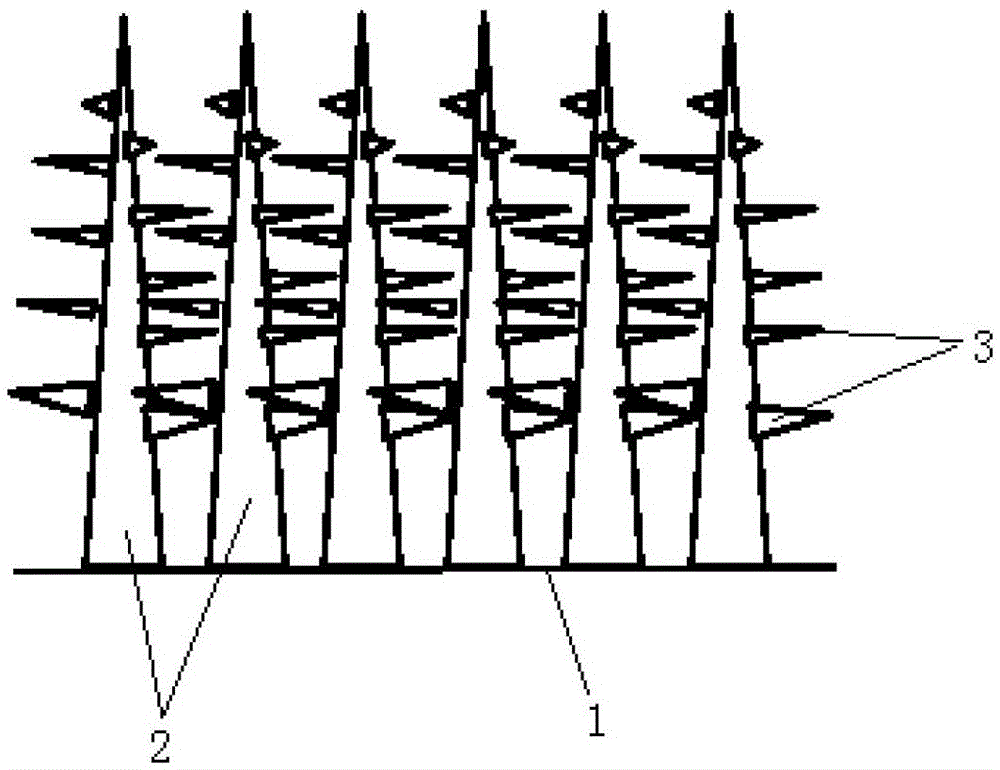

A needle-cone micro-nano double-level array structure material and its preparation method

A dual-level array and structural material technology, applied in the field of needle-cone micro-nano dual-level array structural materials and its preparation, can solve the problems of high manufacturing cost and complicated preparation process, and achieve low cost, high surface activity, and excellent functional properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The needle-cone micro-nano dual-level array structure material is prepared by using copper sheet as the metal substrate, and the steps are as follows.

[0035] (1) Degreasing, pickling, and activation treatment are performed on the surface of the copper sheet that needs hydrophobic treatment. That is, the copper sheet is electrolytically degreased for 60s, washed with distilled water, then pickled in 8% dilute hydrochloric acid for 25s, washed with distilled water, and then activated in 0.15g / L palladium chloride solution.

[0036] (2) Place the copper sheet treated in the step (1) in the electroplating solution, the copper sheet is used as the cathode, and the copper plate is used as the anode, and the copper sheet, the copper plate, the power supply and the electroplating solution are used to form a current loop through wires. The composition of the electroplating solution is: 0.1 mol / L of copper sulfate, 0.1 mol / L of triammonium citrate, 0.1 mol / L of boric acid, 1 pp...

Embodiment 2

[0041] The needle-cone micro-nano dual-level array structure material is prepared by using an aluminum sheet as a metal substrate, and the steps are as follows.

[0042] (1) Degreasing, pickling, and activation treatment are performed on the surface of the aluminum sheet that needs hydrophobic treatment. That is, the aluminum sheet is electrolytically degreased for 30 seconds, washed with distilled water, then pickled in 12% dilute hydrochloric acid for 15 seconds, washed with distilled water, and then activated in 0.25 g / L palladium chloride solution.

[0043](2) Place the aluminum sheet treated in step (1) in the electroplating solution, the aluminum sheet is used as the cathode, and the copper plate is used as the anode, and the aluminum sheet, the copper plate, the power supply and the electroplating solution are used to form a current loop through wires. The composition of the electroplating solution is: 0.12 mol / L of copper sulfate, 2 mol / L of sodium citrate, 1 mol / L of ...

Embodiment 3

[0048] The needle-cone micro-nano dual-level array structure material is prepared by using the iron sheet as the metal substrate, and the steps are as follows.

[0049] (1) Degreasing, pickling, and activation treatment are performed on the surface of the iron sheet that needs hydrophobic treatment. That is to say, the iron sheet is electrolytically degreased for 45s, washed with distilled water, then pickled in 10% dilute hydrochloric acid for 20s, washed with distilled water, and then activated in 0.2g / L palladium chloride solution.

[0050] (2) Place the iron sheet processed in step (1) in the electroplating solution, the iron sheet is used as the cathode, and the copper plate is used as the anode, and the iron sheet, the copper plate, the power supply and the electroplating solution are used to form a current loop through the wires. The composition of the electroplating solution is: 0.5 mol / L copper sulfate, 1 mol / L sodium citrate, 0.5 mol / L boric acid, 1000 ppm EDA, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com