Formulation of extrusion forming wood-plastic foaming decoration section bar and preparation method

A technology for wood-plastic foaming and decorative profiles, which is applied in the field of formulation and preparation of decorative profiles, and can solve problems such as few mentions of formulas and preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

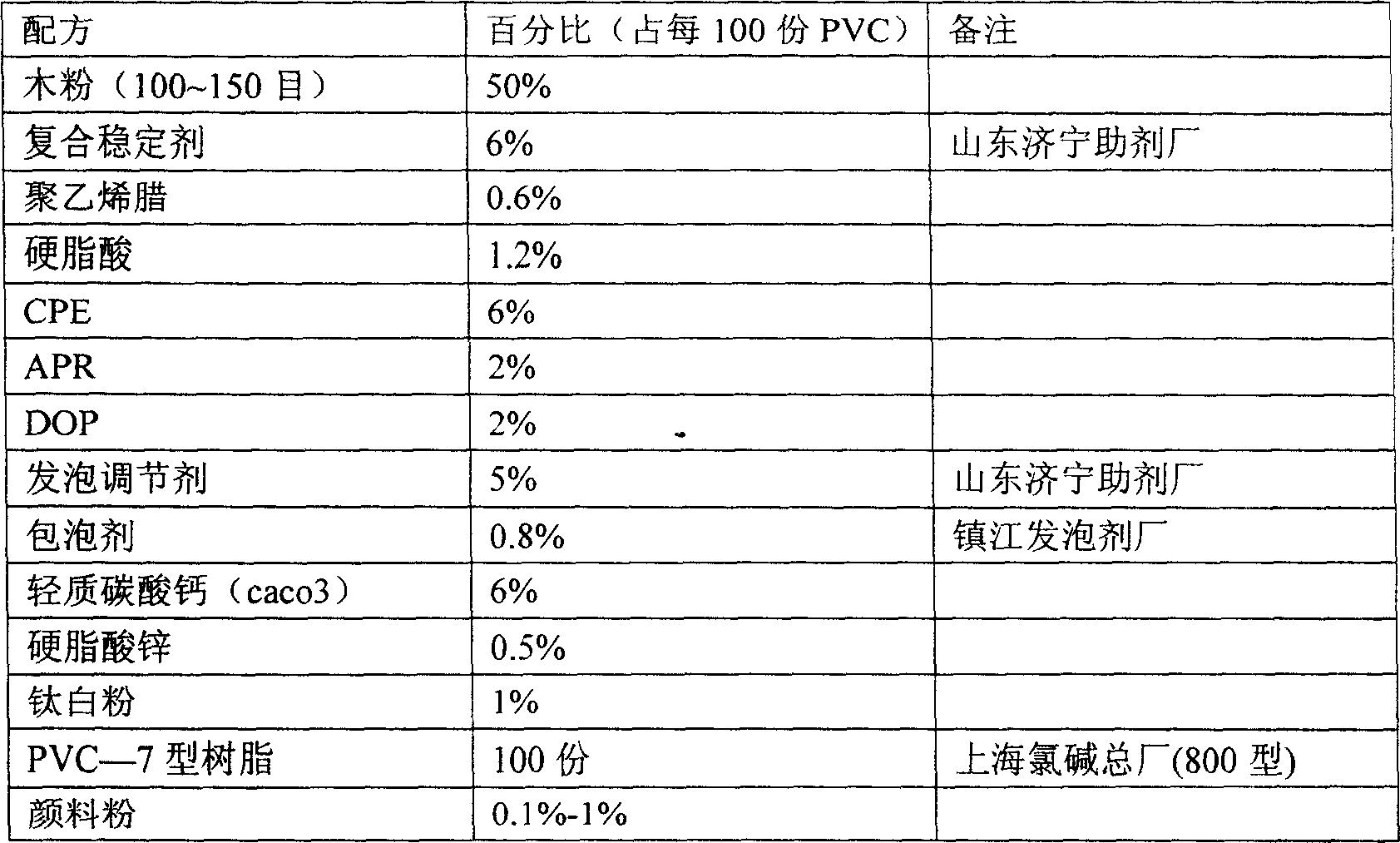

[0013] The formulation of an extruded wood-plastic foamed decorative profile includes plastics, wood powder and additives. The additives include composite stabilizers, external lubricants, internal lubricants, impact modifiers, processing aids, tackifiers, foam regulators, foaming agents, light calcium carbonate CaCo 3 , Foaming aid, anti-aging agent, pigment powder. The external lubricant is polyethylene wax, the internal lubricant is stearic acid, the impact modifier is CPE, the processing aid is ACR, the tackifier is dioctyl phthalate, and the foaming aid is hard Zinc fatty acid and anti-aging agent are titanium dioxide.

[0014] Fig. 1 is the detailed formula form of the wood-plastic foamed decorative profile of the present invention, as shown in Fig. 1, wherein the wood powder is 100-150 mesh, the proportion of wood powder is 50%, and the proportion of composite stabilizer is 6%. The proportion of lubricant is 0.6%, the proportion of internal lubricant is 1.2%, the prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com