Biface smart card and manufacture method thereof

The technology of a dual-interface smart card and its manufacturing method, which is applied in the field of smart cards, can solve the problems of low production efficiency, high cost, unstable quality of dual-interface smart cards, etc., and achieve the effect of reliable quality, stable quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] A method for making a dual-interface smart card, comprising the steps of:

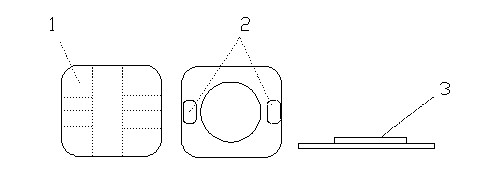

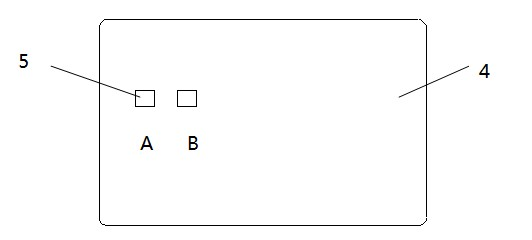

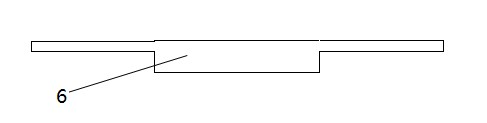

[0029] Step 1: Punch holes for placement of conductive pads. see figure 2 , on the central core layer 4 in the card body 11, two conductive pad placement holes A and B are punched out, and the punching area is located in the position area of a layer of slots 8 to be milled out in the subsequent slot milling process, And avoid the location area of the two-layer groove 9.

[0030] The shape of the hole depends on the shape of the conductive pad. In this embodiment, the two holes are in the shape of a "mouth". The size of the hole is controlled at 2.5*2.5mm. mm, the distance from the upper edge of the card body is 23.9±0.3mm, holes A and B are arranged in parallel, and the distance between the two holes is 11.2±0.3mm.

[0031] Step 2: Fill the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com