Wall building machine

A technology of wall-laying machine and frame, which is applied in the direction of construction, building structure, and building material processing, etc., which can solve the problems of inability to realize simultaneous operations, and achieve the effects of high automation, stable and reliable quality, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

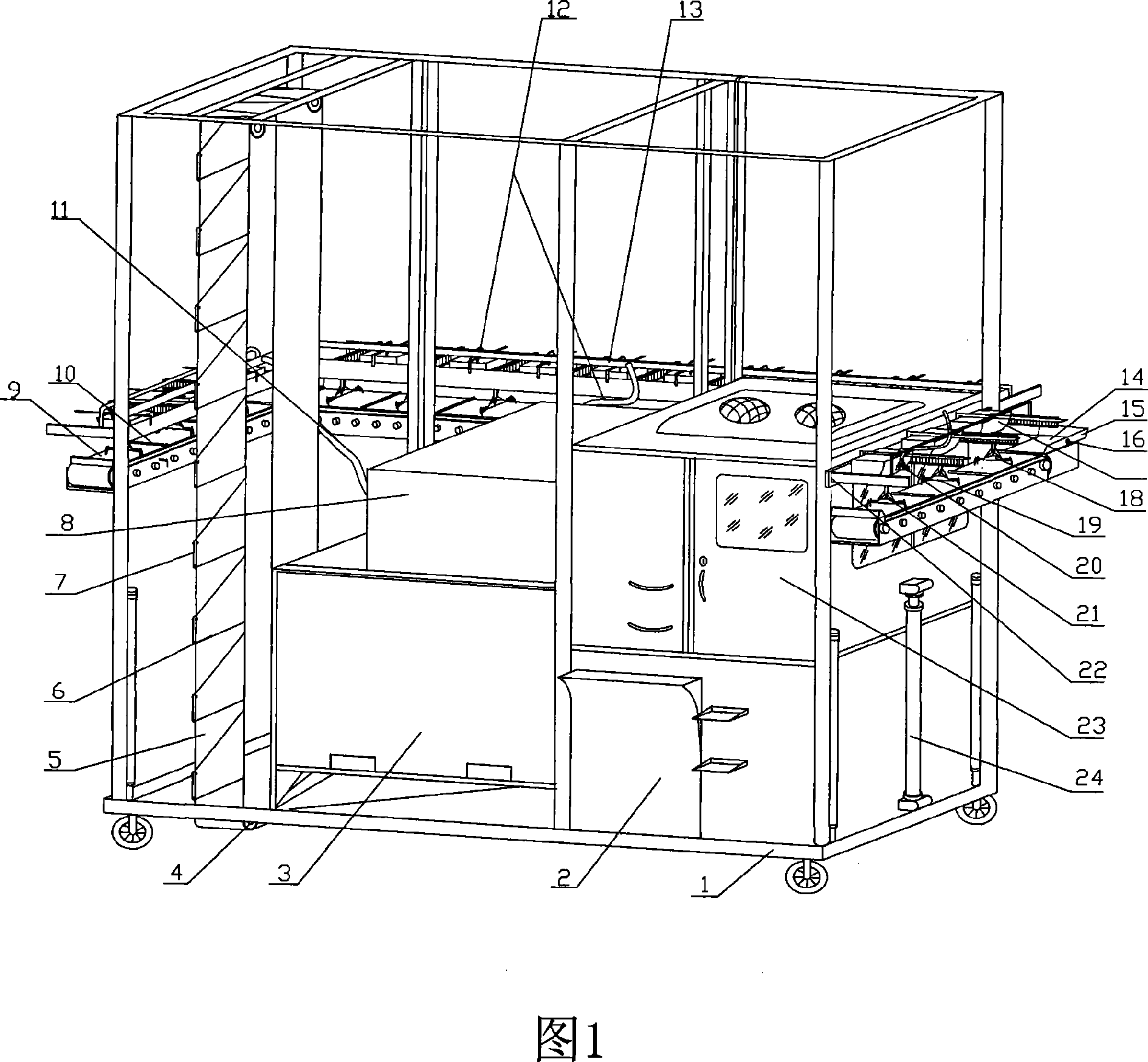

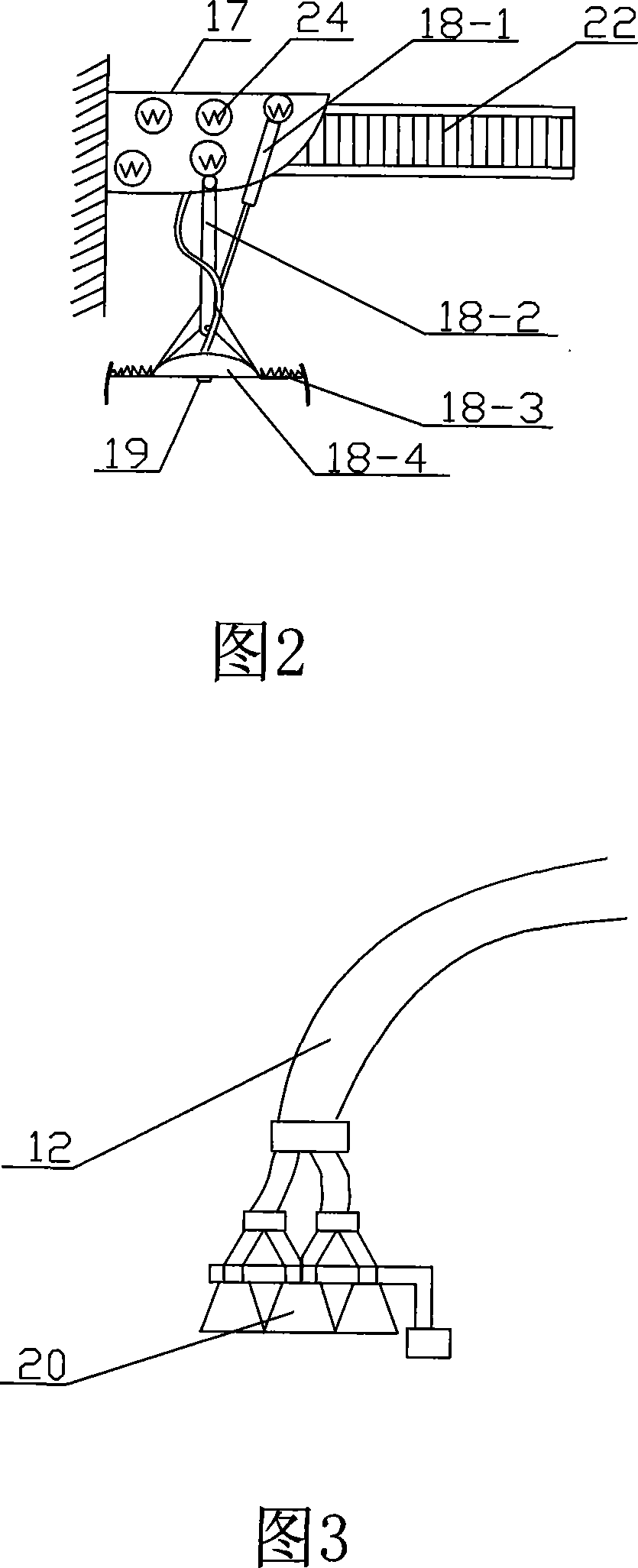

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings. As shown in Figure 1, the main structure of the present invention comprises brick placement box 3, brick delivery device, mortar placement box 2, mortar delivery unit, control device and bricklaying machine head 17, the brick outlet of brick placement box 3 Corresponding to the brick lifting and conveying device, the brick outlet of the brick lifting and conveying device corresponds to the brick horizontal conveying device on one side of the frame 1, and the brick horizontal conveying devices on each side are sequentially connected by the brick steering device 14, The mortar placement box 2 is connected to the bricklaying machine head 17 side by the pressure box 8 and the mortar delivery main pipe 11 of each side. On the bricklaying machine head 17, the mortar shunt filling pressure head 21 is fixedly installed, and the bricklaying machine head 17 is evenly spaced on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com