Modular metal constructing forming method

A modular, metal technology, applied in the direction of metal rolling, metal processing equipment, electron beam welding equipment, etc., can solve the problems of overall billet scrapping, high equipment requirements, and difficult forming, so as to achieve reliable quality, reduce production costs, Improve the effect of tensile stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

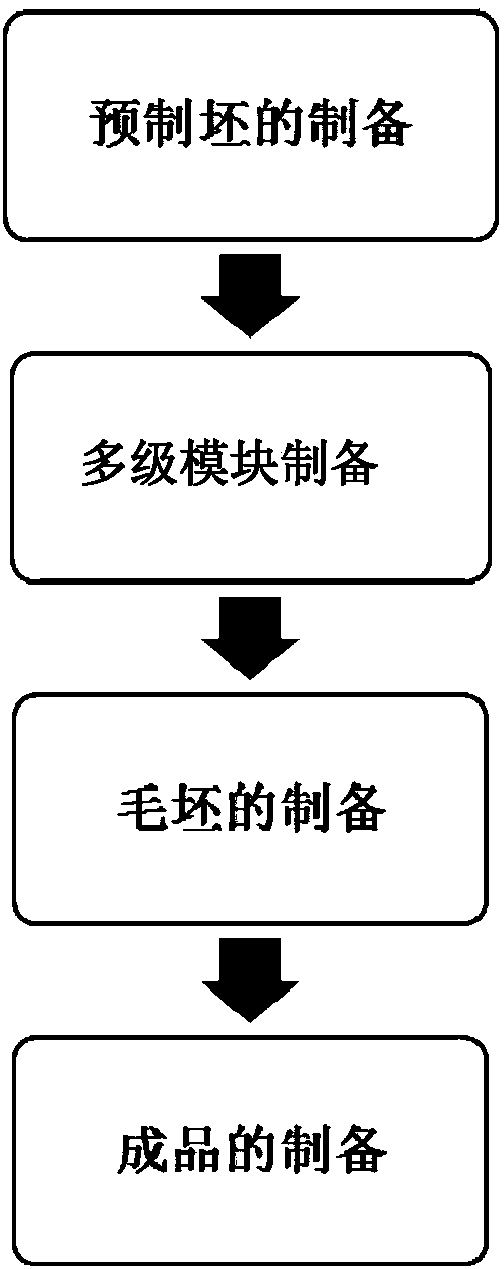

[0026] The preparation of step (2) multi-level module,

[0027] (2-1) First, the preforms are welded in pairs in a vacuum chamber to make 2 N-1 a Class I module,

[0028] (2-2) Then, after heating the first-level module, perform upsetting deformation along the height direction and heat preservation between forgings to make an intermediate blank,

[0029] (2-3) Next, the intermediate blanks are welded in pairs in the vacuum chamber to make 2 N-2 A level II module, and perform upsetting deformation along the height direction and heat preservation between forgings after heating the level II module. Depending on the number of preforms, this step may have to be repeated several times;

[0030] Step (3) making the intermediate blank into a blank;

[0031] Step (4) processing the blank into components or parts.

[0032] In the present invention, the class I modules made of preforms and the class II modules or multi-stage modules made of intermediate blanks are all hourglass-shape...

Embodiment 1

[0038] The target product of this embodiment is a large ring forging.

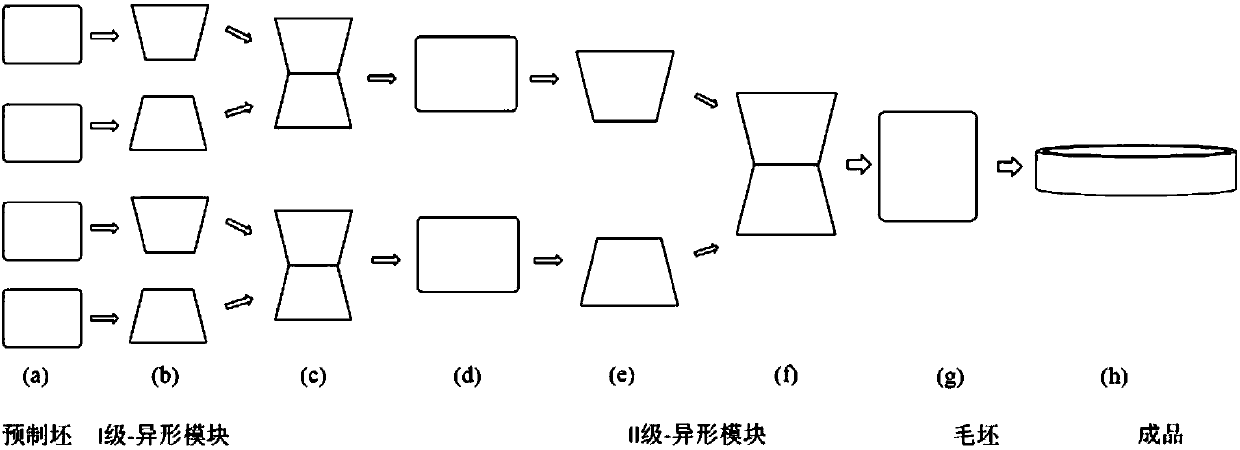

[0039] The first step is to obtain steel ingots by pouring, heat the steel ingots and open forging to form preforms. The dimensions of the preforms are: diameter 2100mm, height 1500mm, see figure 2 (a).

[0040] In the second step, the preform is heated before forging, and the maximum heating temperature is not lower than 1200°C. Die forging the preform to form a class I frustum shape unit, see figure 2 (b).

[0041]In the third step, vacuum electron beam welding is performed on the I-level frustum-shaped unit. In the vacuum chamber, vacuum electron beam sealing welding is performed on the stacked I-level frustum-shaped unit blanks, and the welding depth is 20-50mm to form an I-level hourglass-shaped module. See figure 2 (c).

[0042] The fourth step is to heat the welded Class I hourglass-shaped module before forging, and the maximum heating temperature is not lower than 1200°C. Place the heated ...

Embodiment 2

[0049] The target product of this embodiment is a large tube blank.

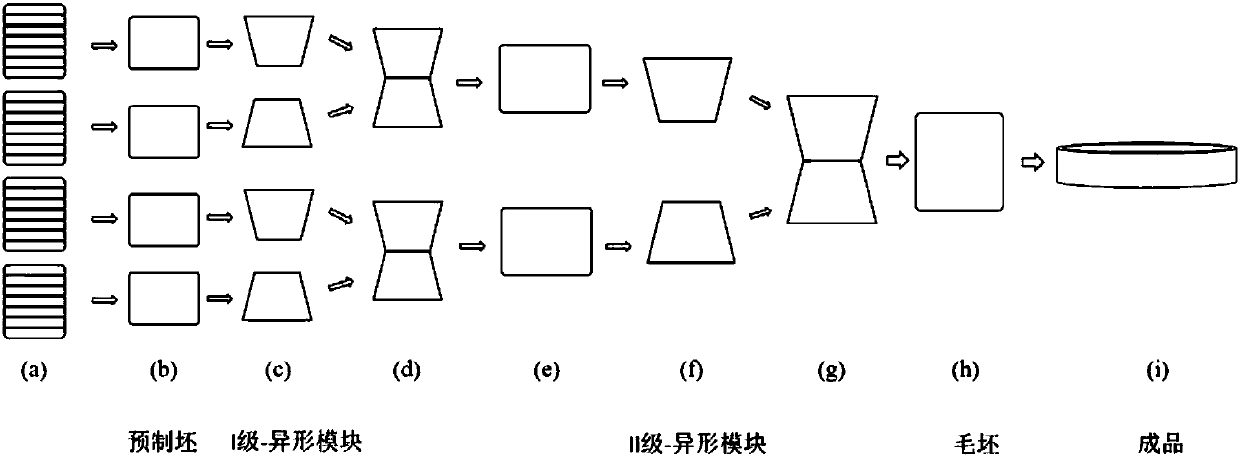

[0050] In the first step, the stainless steel continuous casting slab made by continuous casting is cut into 11 billets with a size of 1500mm×1500mm×200mm. The 6 sides of each continuous casting slab are machined and the surface to be welded is cleaned to expose a fresh metal surface.

[0051] In the second step, vacuum electron beam welding is carried out on the blank. In the vacuum chamber, carry out vacuum electron beam sealing welding on the surroundings of the stacked blanks, the welding depth is 20-50mm, and the dimensions after welding are: width 1500mm, length 1500mm, height 2200mm, see image 3 (a).

[0052] The third step is to heat the welded blank before forging. The maximum heating temperature is not lower than 1200°C, and the heating rate is required to be lower than 100°C / h. Place the heated billet on the press console so that the height direction of the billet is along the vertical directi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com