Extraction and preparation process of moxa floss moxibustion sticks and smokeless moxa sticks

A preparation process, the technology of moxa, which is applied in the field of extraction and preparation process, can solve the problems of inconsistent quality and low quality, achieve the effect of less impurity content, reliable quality, and solve the effect of choking smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

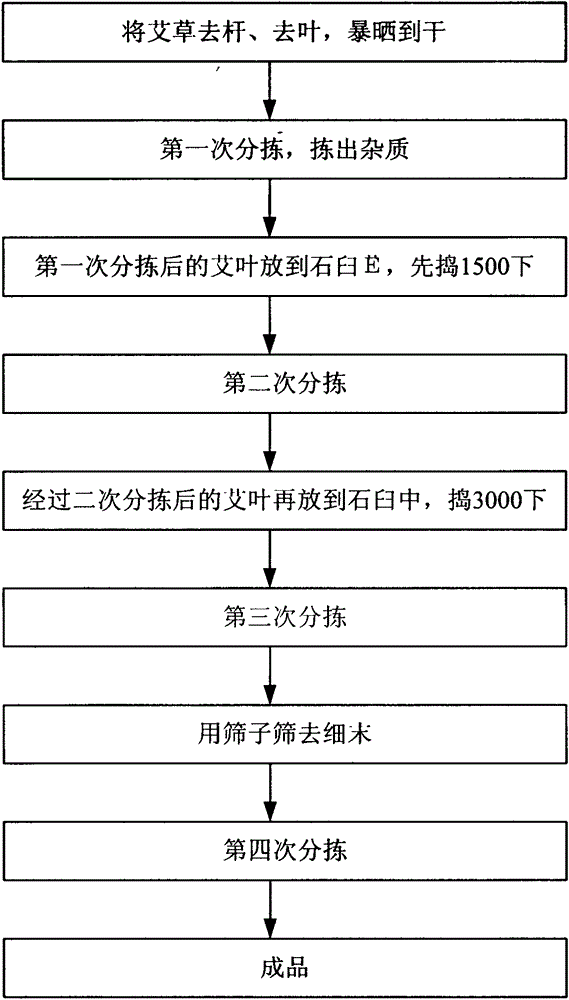

[0019] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0020] Such as figure 1 As shown, the extraction and preparation process of moxa moxibustion sticks and smokeless moxa sticks of the present invention comprises the following steps:

[0021] Step 1: Remove the stems from the collected wormwood, remove the stems and leave only the wormwood leaves, and put the wormwood leaves in a sunny place for several times to dry, instead of drying them with a dehydrator and dryer;

[0022] Step 2: The dried wormwood is stored for a long time, and it is sorted for the first time to remove impurities;

[0023] Step 3: Put the first sorted mugwort leaves into the stone mortar and pound them 1500 times;

[0024] Step 4: After pounding out the mugwort leaves, perform the second sorting;

[0025] Step 5: put the mugwort leaves after the second sorting in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com