Variable-frequency oscillation high-voltage electrostatic down fiber removing machine

A high-voltage static electricity and desilter technology, which is applied in textiles and papermaking, fiber treatment, fiber separation, etc., can solve the problem of difficult separation of velvet and achieve good safety protection, reliable quality, and high separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

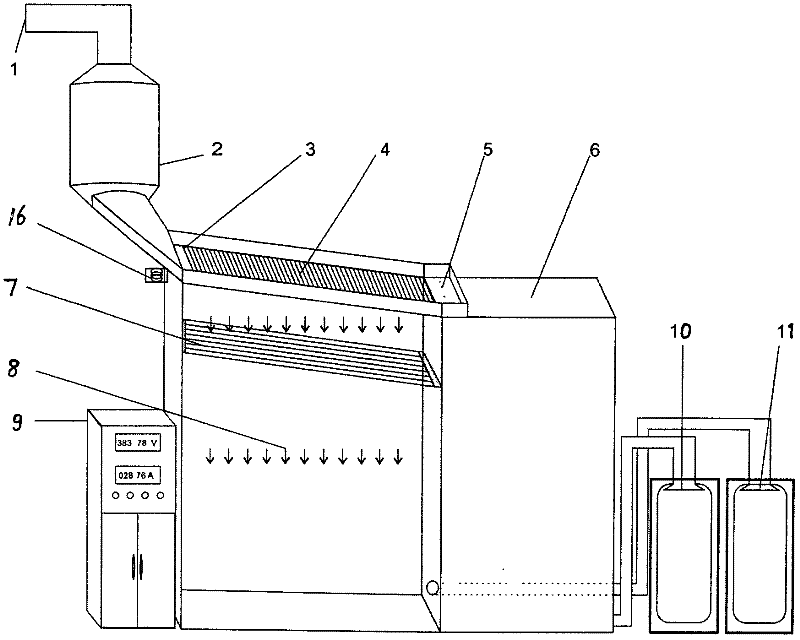

[0015] Embodiment: frequency conversion oscillating high-voltage electrostatic down desilting machine

[0016] The specific structure is that the down inlet 1 is the storage barrel 2, the down outlet 3 corresponds to the bar vibrating screen 4, the down end is the down inlet 5, and the down bin 6 is connected to the down through the pipeline. Enter the velvet baler 10, the bottom of the strip vibrating screen 4 is provided with an electrostatic screen 7, the bottom of which is a flying silk bin 8, which is connected to the flying silk baler 11 through a pipeline, and all power lines are connected to the control electrical cabinet 9.

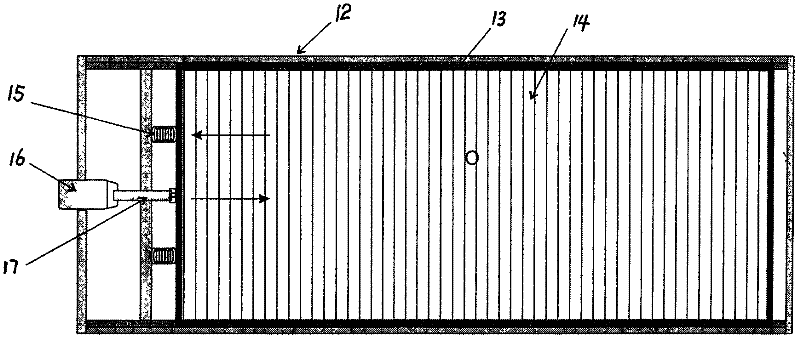

[0017] Among them, the structure of the bar vibrating screen 4 is that the fixed bracket 12 is provided with a moving bracket 13, and a strip screen 14 is arranged on it. The fixed bracket 12 and the moving bracket 13 are connected by a spring 15, and an electromagnet is also arranged on the fixed bracket. 16. The electromagnet push rod 17 on it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com