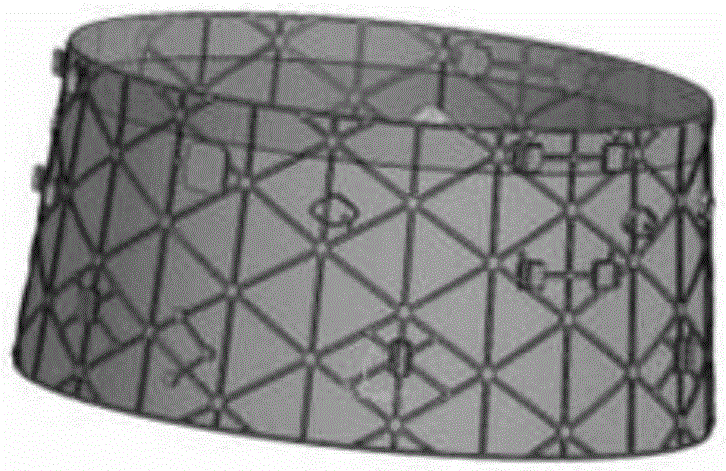

Deep chemical milling method of TA12 and TA15 titanium-alloy large-scale structural components

A large-scale structural part, chemical milling technology, applied in the field of deep chemical milling of TA12, TA15 titanium alloy large-scale structural parts, can solve problems such as shortening production cycle, and achieve the effect of reducing connection strength, feasible process and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In the present embodiment, the formula of chemical milling fluid is as follows:

[0060]

[0061] the rest is water;

[0062] Temperature 15°C.

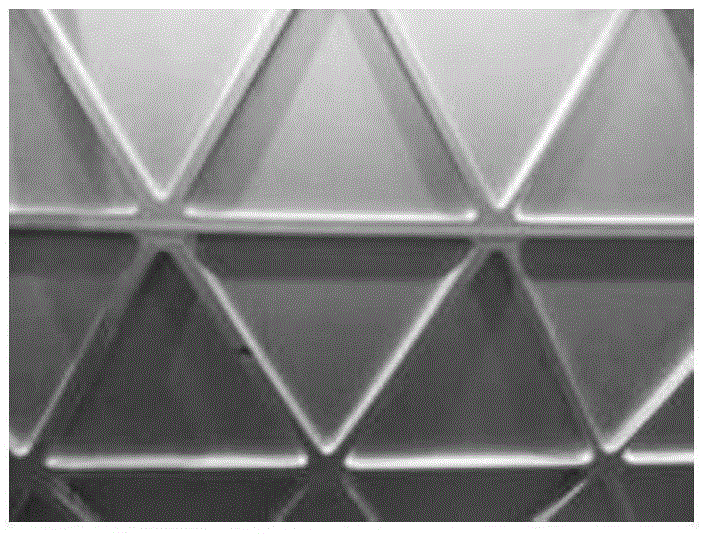

[0063] The motor speed is 120 rpm, and the rotation direction of the motor is changed every 15 minutes. The wall thickness of the part is chemically milled from 10mm to 1.1mm, and the hydrogen content test result is 65ppm. After chemical milling, the surface of the TA12 titanium alloy part is smooth without irregularities. etch marks, pits and pits. The surface of the machined part is free of any dirt, residue, surface film and other unwanted items. The chemical milling line should be clearly defined, and whether the shape and size meet the requirements of the drawing.

Embodiment 2

[0065] In the present embodiment, the formula of chemical milling fluid is as follows:

[0066]

[0067] the rest is water;

[0068] The temperature is 28°C.

[0069] The motor speed is 125 rpm, and the rotation direction of the motor is changed every 15 minutes. The wall thickness of the part is chemically milled from 10mm to 0.9mm, and the hydrogen content test result is 55ppm. After chemical milling, the surface of the TA12 titanium alloy part is smooth and there is no irregular dip etch marks, pits and pits. The surface of the machined part is free of any dirt, residue, surface film and other unwanted items. The chemical milling line should be clearly defined, and whether the shape and size meet the requirements of the drawing.

Embodiment 3

[0071] In the present embodiment, the formula of chemical milling fluid is as follows:

[0072]

[0073] the rest is water;

[0074] The temperature is 40°C.

[0075] The motor speed is 130 rpm, and the rotation direction of the motor is changed every 15 minutes. The wall thickness of the part is chemically milled from 10mm to 0.9mm, and the hydrogen content test result is 45ppm. After chemical milling, the surface of the TA15 titanium alloy part is smooth without irregular immersion etch marks, pits and pits. The surface of the machined part is free of any dirt, residue, surface film and other unwanted items. The chemical milling line should be clearly defined, and whether the shape and size meet the requirements of the drawing.

[0076] The results of the examples show that the present invention is applied in the manufacture of aero-engine parts, effectively guaranteeing product quality and meeting the requirements of design drawings. At the same time, the processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com