Preparation method of high-purity tacrolimus

A tacrolimus, high-purity technology, applied in the preparation of separation and purification of tacrolimus, and the preparation of pharmaceutical raw materials, can solve the problems of low crystallization yield and high impurity content, achieve high yield, simple process, improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

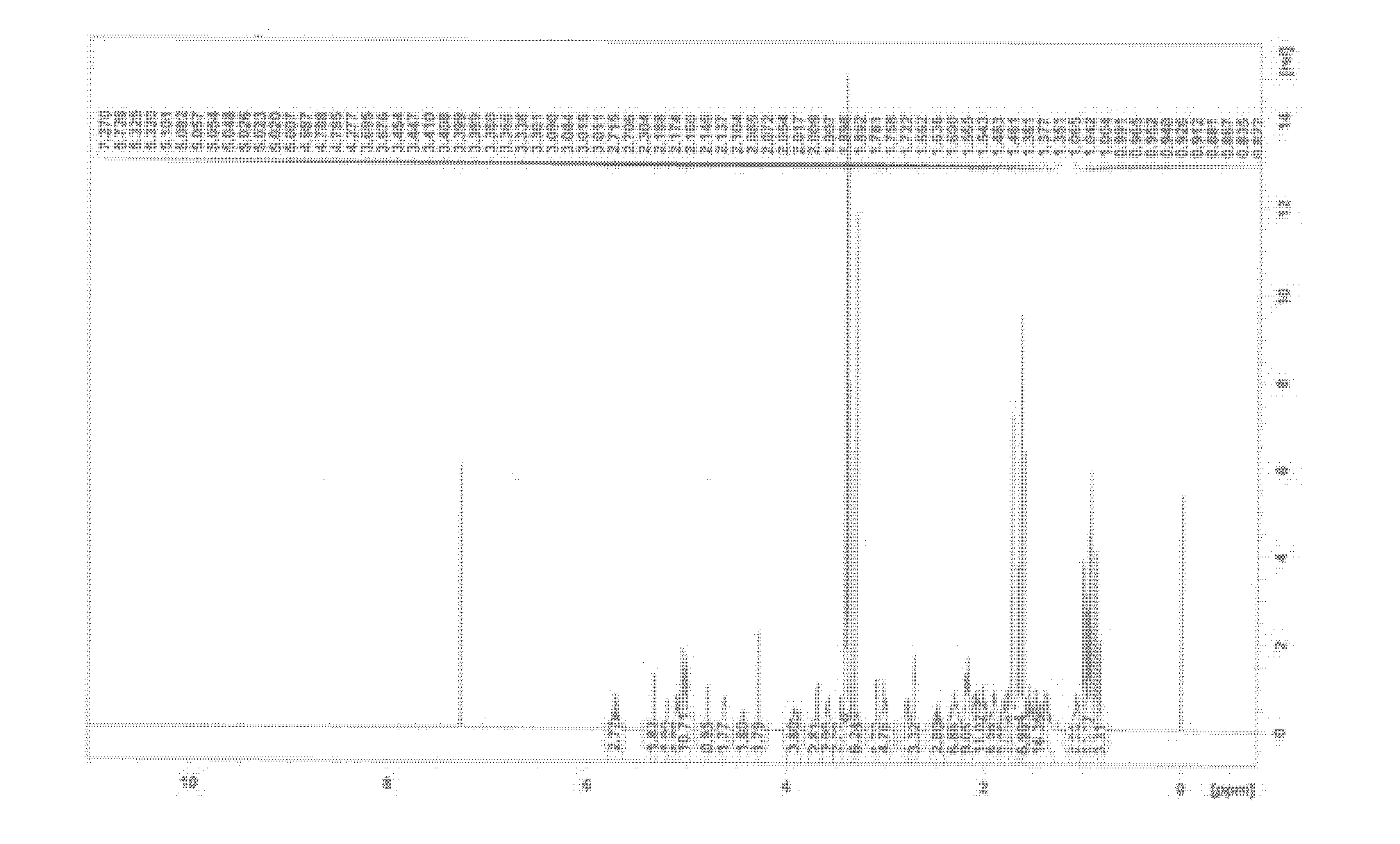

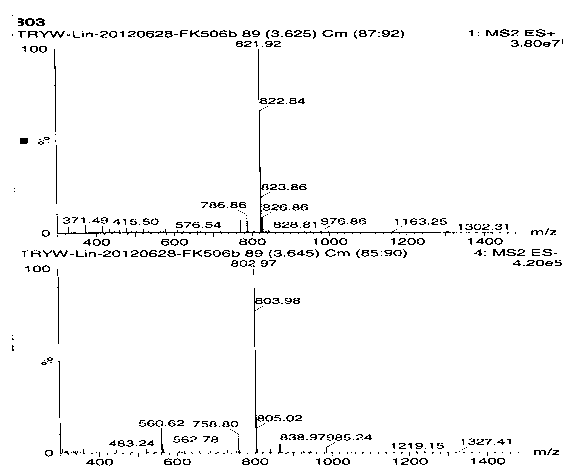

Image

Examples

Embodiment 1

[0037] First, 10 L of tacrolimus fermentation broth with a fermentation unit of 487 μg / mL was taken, and the tacrolimus fermentation broth was subjected to vacuum filtration to separate solid and liquid from the tacrolimus fermentation broth to obtain 3.1 kg of mycelia. Add 6.2 L of 95% ethanol solution to the mycelia, soak and stir for 1 hour, then vacuum filter the solution, and collect the tacrolimus extract. Then dilute the above-mentioned tacrolimus extract with water to 30% by volume of ethanol, the diluted extract is decolorized by the LX-900 macroporous decolorizing resin column with a loading capacity of 500mL, and the decolorized solution of gained Then introduce XF-800 macroporous adsorption resin column for adsorption, the resin loading capacity of the macroporous adsorption resin column used is 500mL, and the flow rate of introduction is 750mL / h. Then the XF-800 resin column adsorbed with tacrolimus was first washed with 750mL ethanol aqueous solution with a volum...

Embodiment 2

[0040] In this example, 30 L of tacrolimus fermentation broth with a fermentation unit of 491 μg / mL was firstly taken, and the tacrolimus fermentation broth was subjected to vacuum filtration to separate the solid and liquid of the tacrolimus fermentation broth to obtain 9.4 kg of mycelium . Add 28.2 L of 85% isopropanone to the above mycelia, soak and stir for 1 hour, then vacuum filter the solution, and collect the tacrolimus extract. Then dilute the above-mentioned tacrolimus extract with water to a volume percent concentration of isopropanone of 25%, and this diluted extract is decolorized by the LSA-700 macroporous decolorizing resin column with a loading capacity of 2000mL, and the decolorized The liquid is then introduced into the D101 macroporous adsorption resin column for adsorption. The resin loading capacity of the macroporous adsorption resin column used is 2000mL, and the flow rate of the decolorization solution is 3000mL / h. Then the D101 resin column adsorbed w...

Embodiment 3

[0043] In this example, firstly, 50 L of tacrolimus fermentation broth with a fermentation unit of 476 μg / mL was taken, and the tacrolimus fermentation broth was subjected to vacuum filtration to separate the solid and liquid of the tacrolimus fermentation broth to obtain 15.2 kg of mycelium . Add 60.8 L of 90% methanol to the above mycelium, soak and stir for 1 hour, then vacuum filter the solution, and collect the tacrolimus extract. Then dilute the above-mentioned tacrolimus extract with water to a methanol volume percentage of 40%, the diluted extract is decolorized by a LX-900 macroporous decolorizing resin column with a loading capacity of 2500mL, and the decolorized solution of the obtained Then import the D101 macroporous adsorption resin column for adsorption. The resin loading capacity of the macroporous adsorption resin column used is 2500mL, and the flow rate of the decolorization solution is 3750mL / h. Then, the D101 resin column adsorbed with tacrolimus was first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com