Solvent-free composite machine

A solvent-free laminating machine and frame technology, applied in lamination device, lamination auxiliary operation, control lamination and other directions, can solve the hidden danger of unsightly structure, unsuitable operation needs, failure to meet product quality standards and efficiency Standard and other issues, to achieve the effect of solving the overloaded workload, elegant appearance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

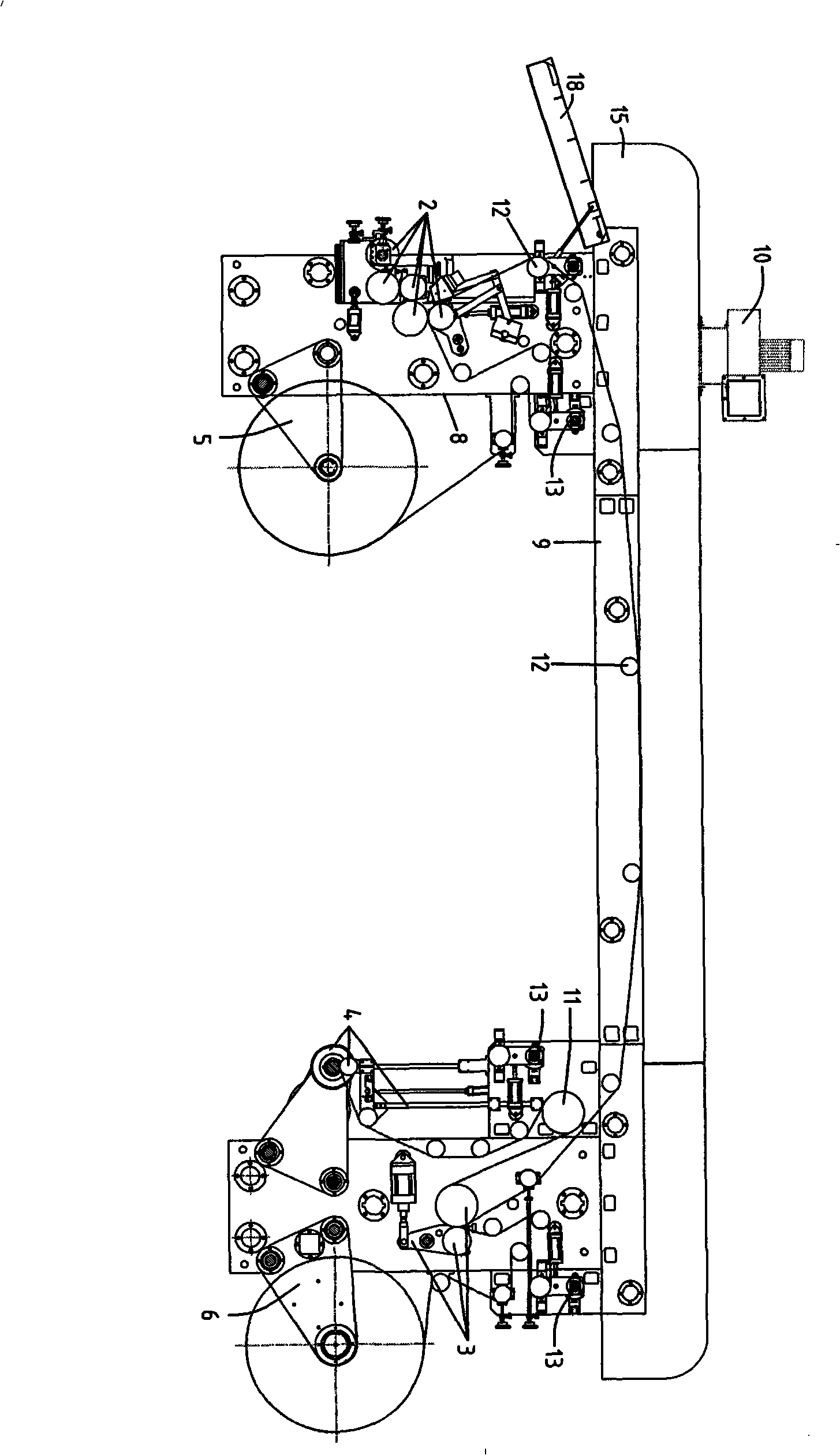

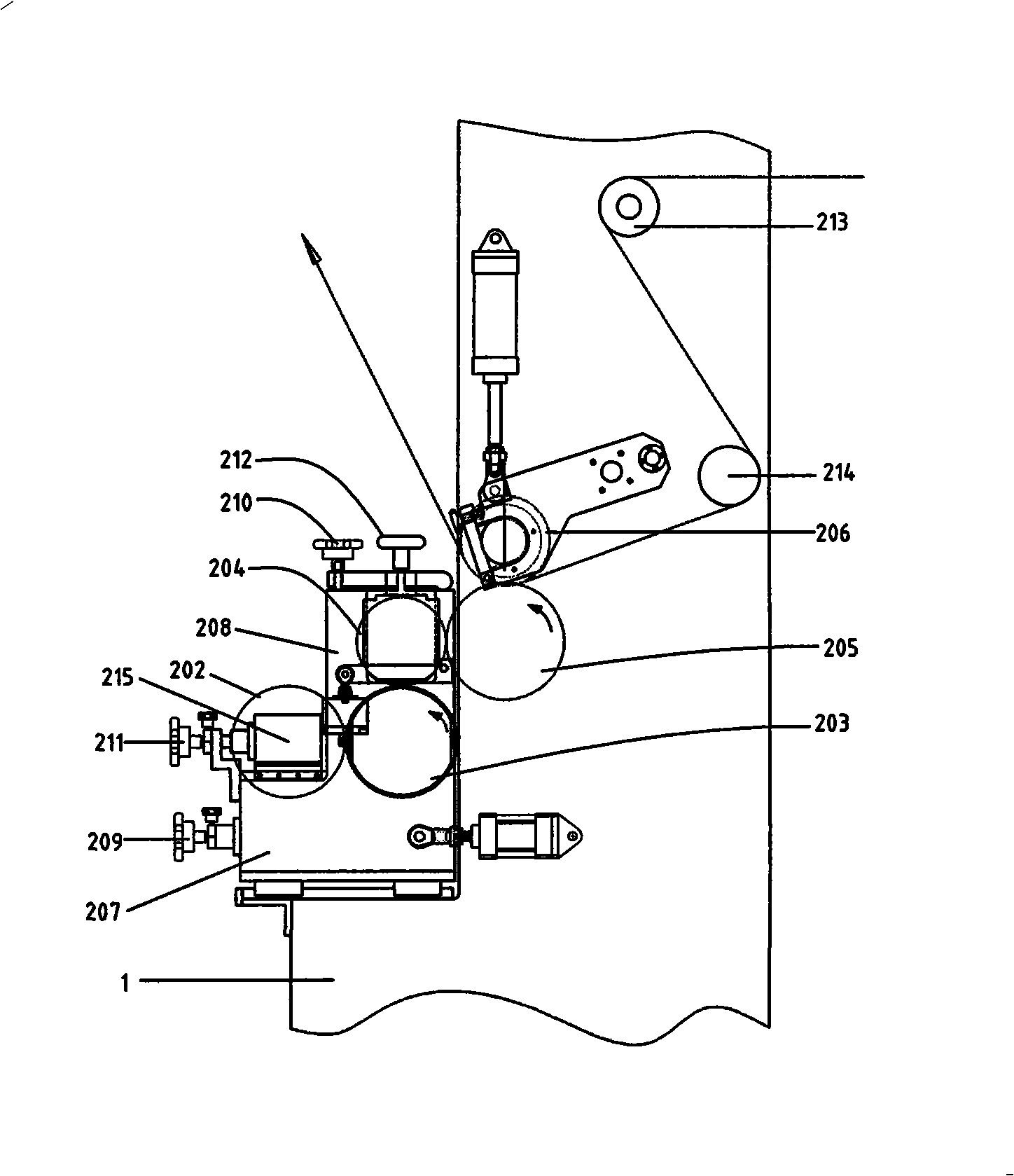

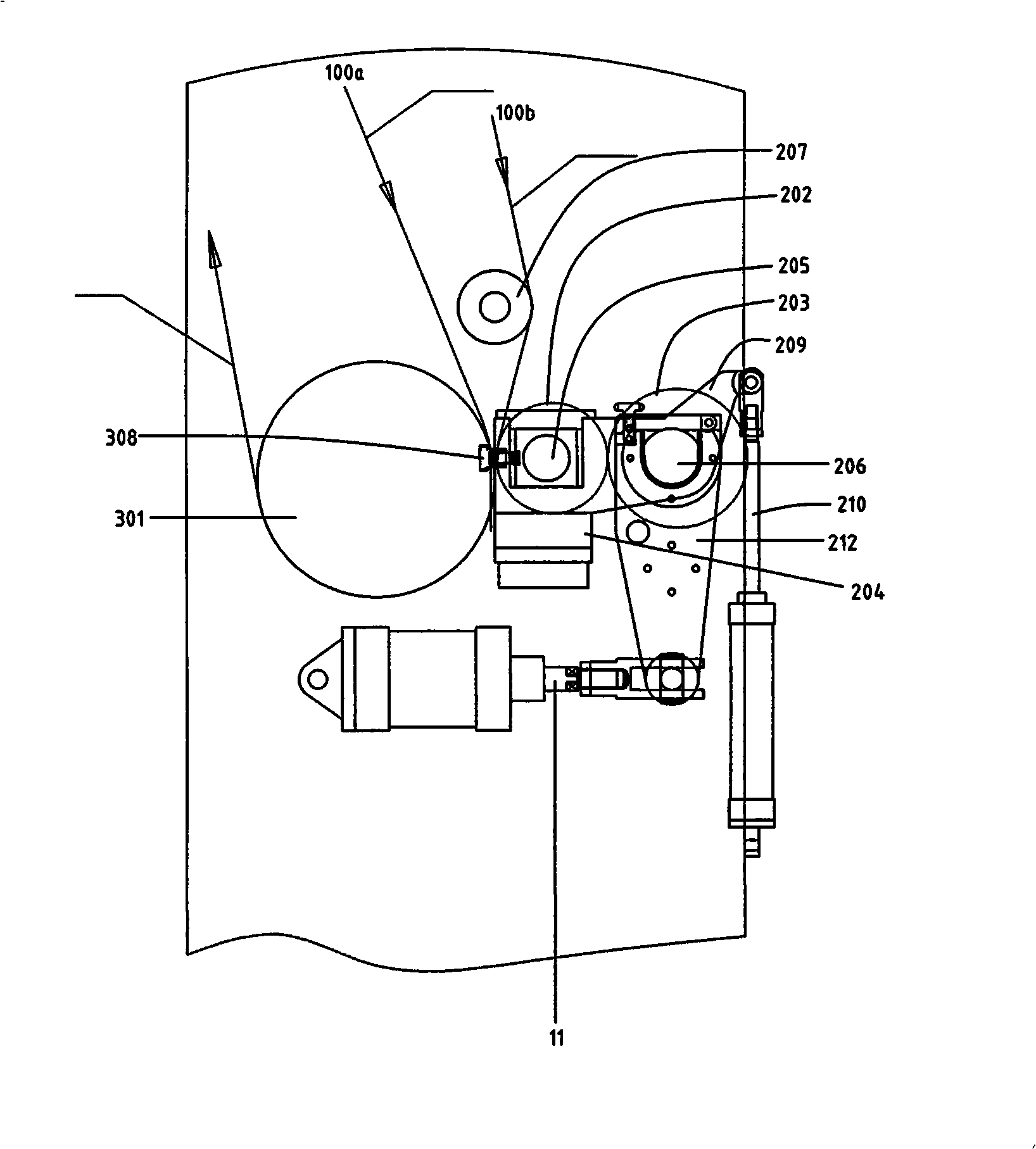

[0020] Please refer to figure 1 The utility model consists of a frame 1, a coating mechanism 2, a composite mechanism 3, a winding mechanism 4, a first unwinding mechanism 5, a second unwinding mechanism 6, a power mechanism 7, a wall panel 8, a machine top 9, and waste gas recovery Part 10, cooling roller 11, transition roller 12 groups, swing tension roller 13 groups, control box 14; the arc-shaped dust cover 15 is arranged on the top of the machine top 9; the exhaust gas recovery part 10 is installed on the dust cover 15, and the exhaust gas The area between the wall panels 8 on both sides of the coating mechanism 2 corresponding to the recovery part 10 below; the coating mechanism 2 and the wall panels 8 on the back of the composite mechanism 3 are equipped with a safety shield 16, and the coating mechanism 2 and the composite mechanism 3 A control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com