Weld joint surface defect detection method and system based on machine vision

A welding seam surface and defect inspection technology, applied in the field of inspection, can solve the problems of difficulty in objectification, standardization and standardization of inspection results, difficulty in inspection of welding seam of large-scale structural parts, and limited equipment size, etc., and achieves obvious reliability advantages. Avoid human error and test data accurately and objectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

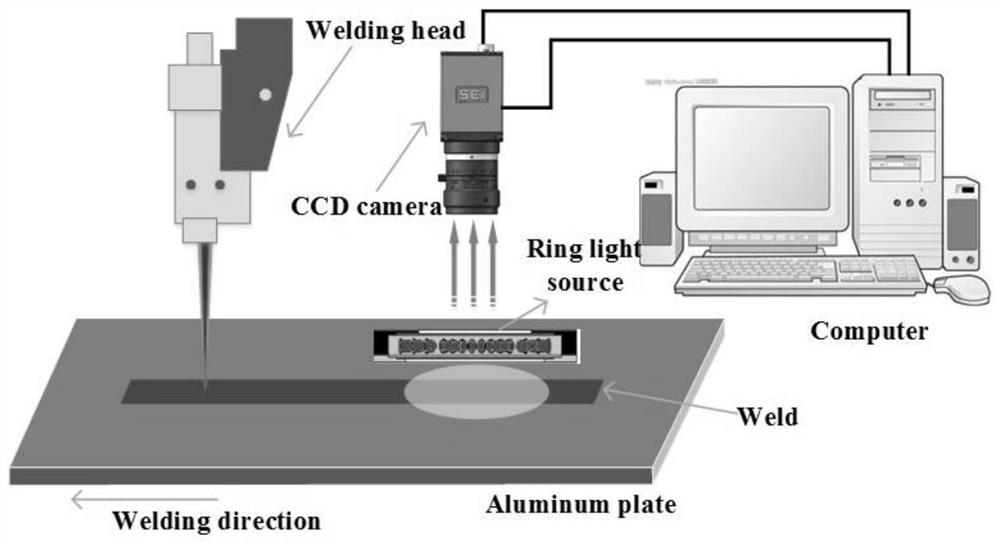

[0044] Such as figure 1 As shown, the hardware of the real-time acquisition platform for weld surface images includes: CCD camera, lens, ring-shaped LED 0° light source, and fixed platform. The camera adopts a CCD 5 million area array camera and supporting lens, controls the photosensitive and weld picture collection through the detection system software, and the collection area is 200x100mm. The ring-shaped LED 0° light source is used as the auxiliary light source. The zero-degree ring-shaped white light source can effectively reflect the flatness of the weld surface through zero-degree lighting. The sunken area will appear dark because the light source cannot be illuminated, and the raised pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com