Manual and automatic integrated passenger train water-feeding valve

A railway passenger car, all-in-one technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of shortened parking time, unable to flush toilets, not meeting the requirements of drinking water equipment, etc., to achieve simple operation, shorten water supply time, The effect of simplifying water-feeding procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

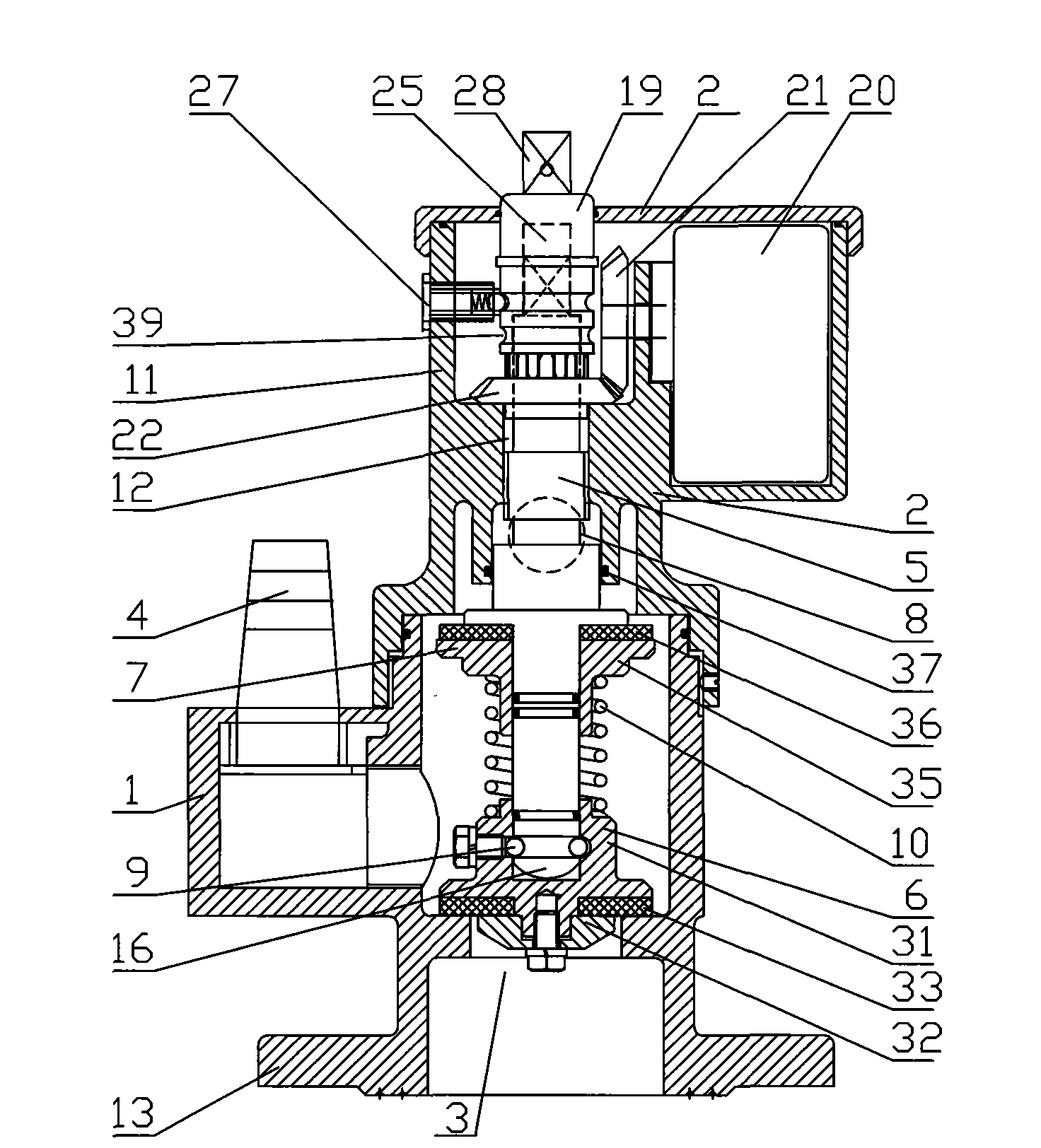

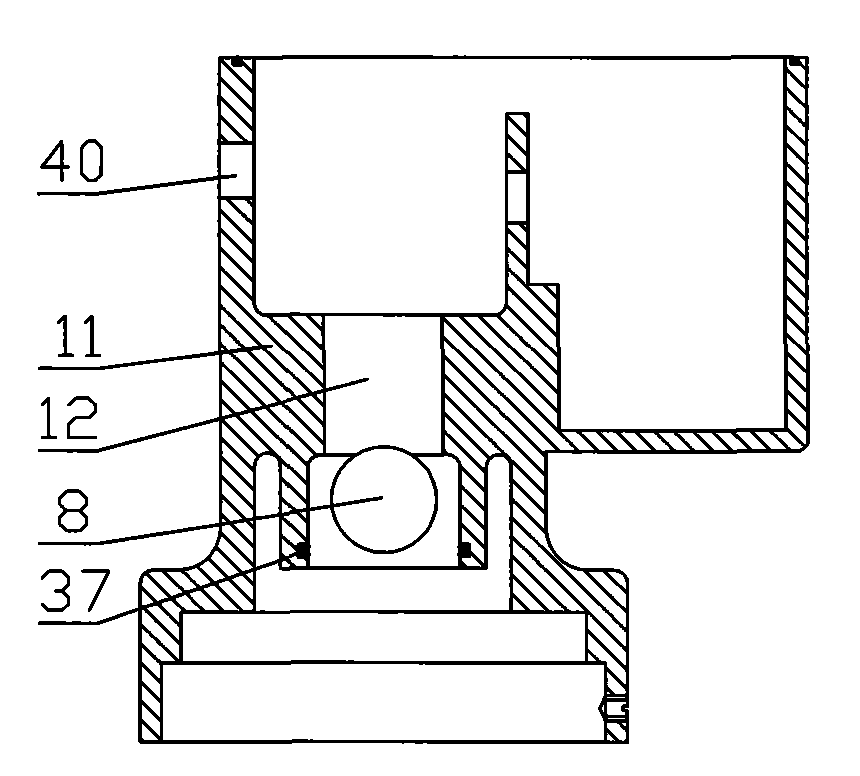

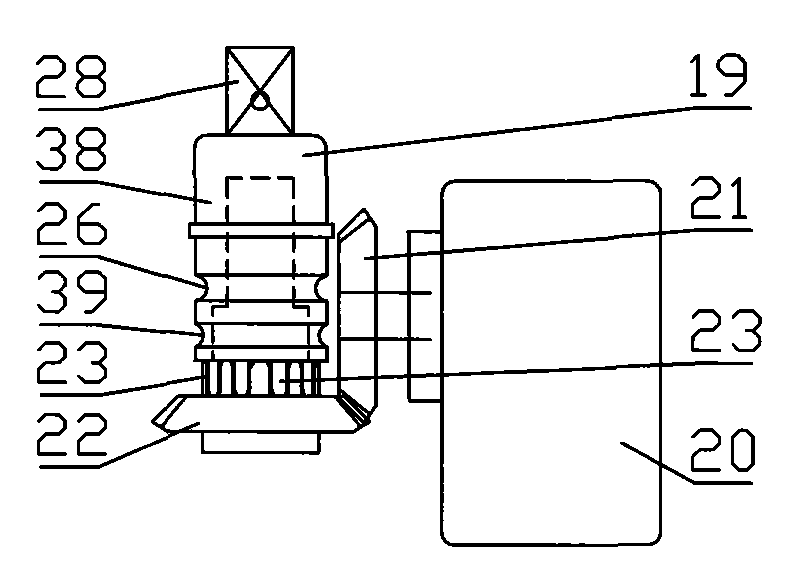

[0026] Embodiment 1: as figure 1 As shown, a water supply valve for a railway passenger car with manual operation includes a valve body 1, a valve cover 2, a water inlet 3 and a water outlet 4. At the bottom of the body 1, there is a water outlet 4 on the side wall of the valve body 1, which also includes a valve stem 5, a water inlet valve head 6, a water return valve head 7, a water return port 8, a limit steel ball 9, and a tension opening Spring 10 and electric driving mechanism 38; Valve stem 5 is placed in valve body 1, and valve stem 5 is a whole rod, is provided with valve stem threaded assembly hole 12 in the upper valve body 11 of valve body 1, and valve stem 5 The upper end is assembled in the threaded assembly hole 12 of the valve stem, and acts as a lead for opening and closing the water inlet valve head 6. A sealing ring 37 is arranged between the bottom of the valve stem threaded assembly hole 12 and the valve stem 5; the water inlet valve head 6 is placed in th...

Embodiment 2

[0035] Embodiment 2: as Figure 11 As shown in the embodiment 1, there are two water outlets 4, and the two water outlets 4 are placed on either side of the side wall of the valve body 1, respectively.

[0036] Working principle: the water inlet valve head 6 and the water return valve head 7 in the valve body 1 are linked by the rotation of the valve stem 5 . When the valve stem 5 is rotated counterclockwise, the water inlet valve head 6 is opened to perform water filling, and at the same time, the water return valve head 7 is linked to close the water return port 8 . When the valve stem 5 is rotated clockwise, the water inlet valve head 6 closes the water inlet 3, and at the same time, the backwater valve head 7 is linked to open the water return port 8, so that the residual water in the upper water pipe can automatically return to the well and prevent the upper water pipe from freezing in winter.

[0037] When working automatically: the electric manual switching limiter 27 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com