Bowstring Cam for Compound Bow

a bow and compound bow technology, applied in bows/crossbows, white arms/cold weapons, weapons, etc., can solve the problems of waste of power limb energy, difficulty in achieving goals, and bowstring not optimally accelerating arrows, so as to improve the overall behavior of compound bows, accelerate bowstring and arrow, and equal flexing of upper and lower power limbs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The compound bow on which the improved bowstring cam may be employed is described in my earlier U.S. Pat. No. 6,776,148, and that bow is described briefly here, but the contents of that patent are incorporated here by reference.

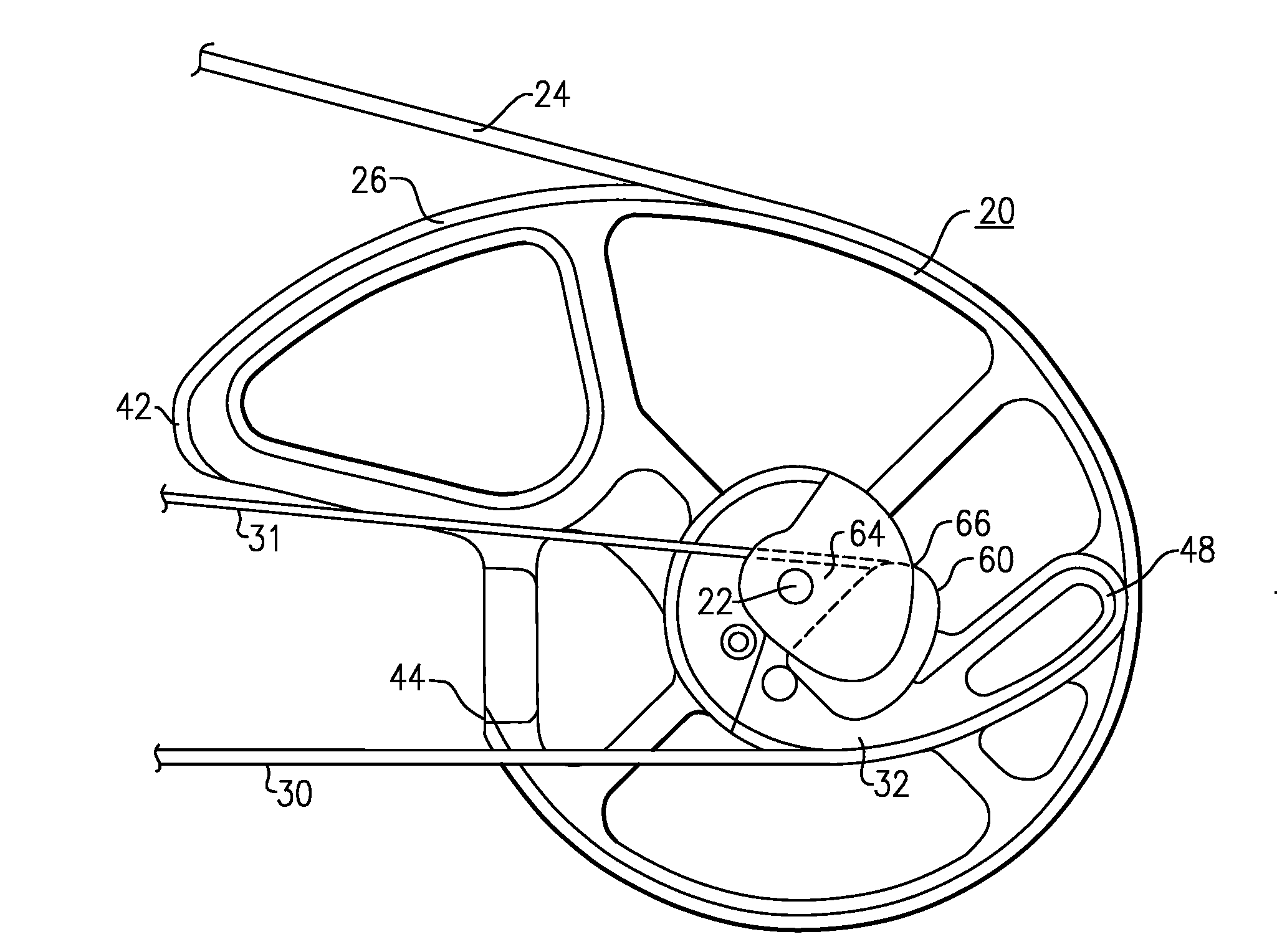

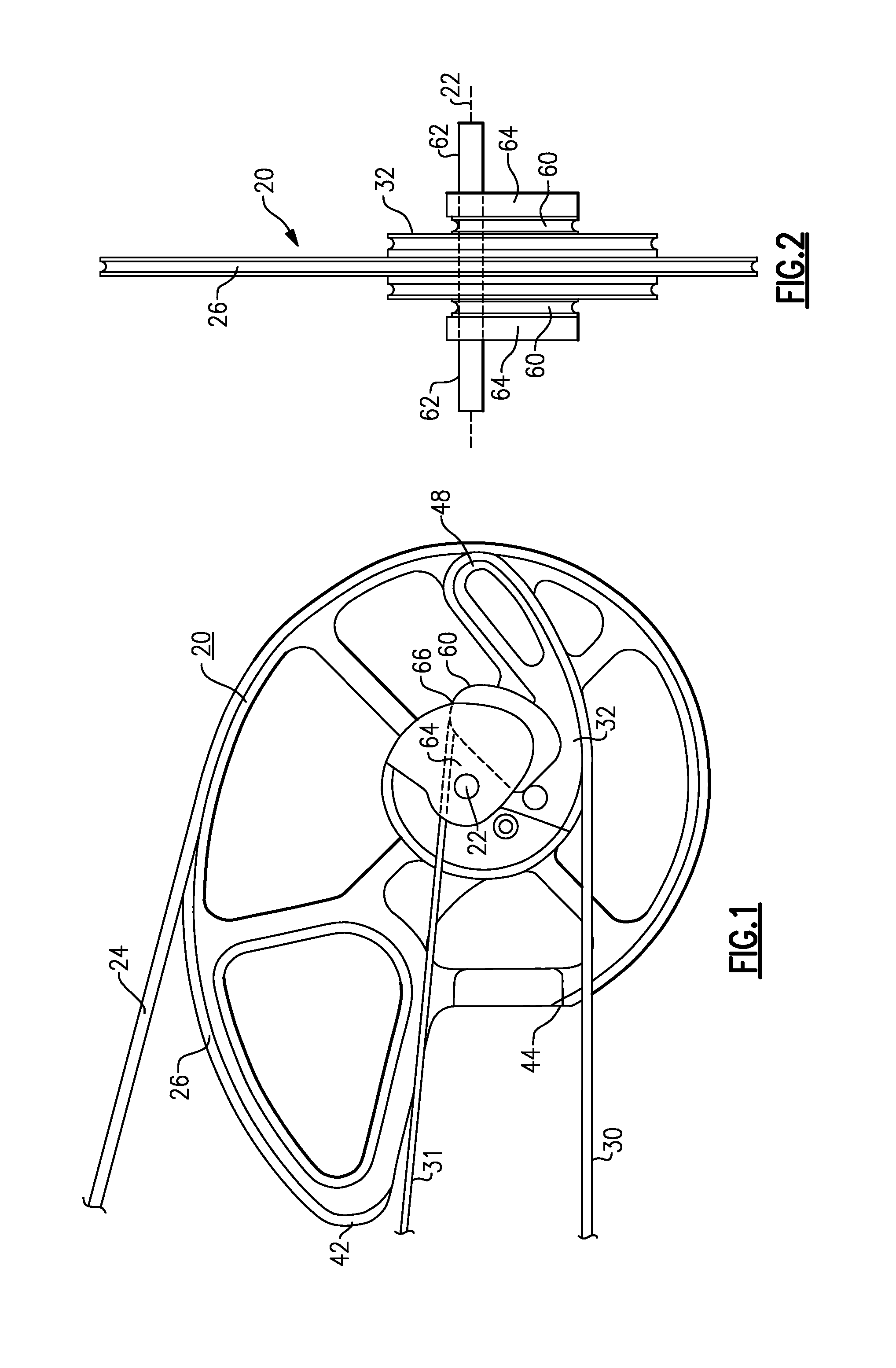

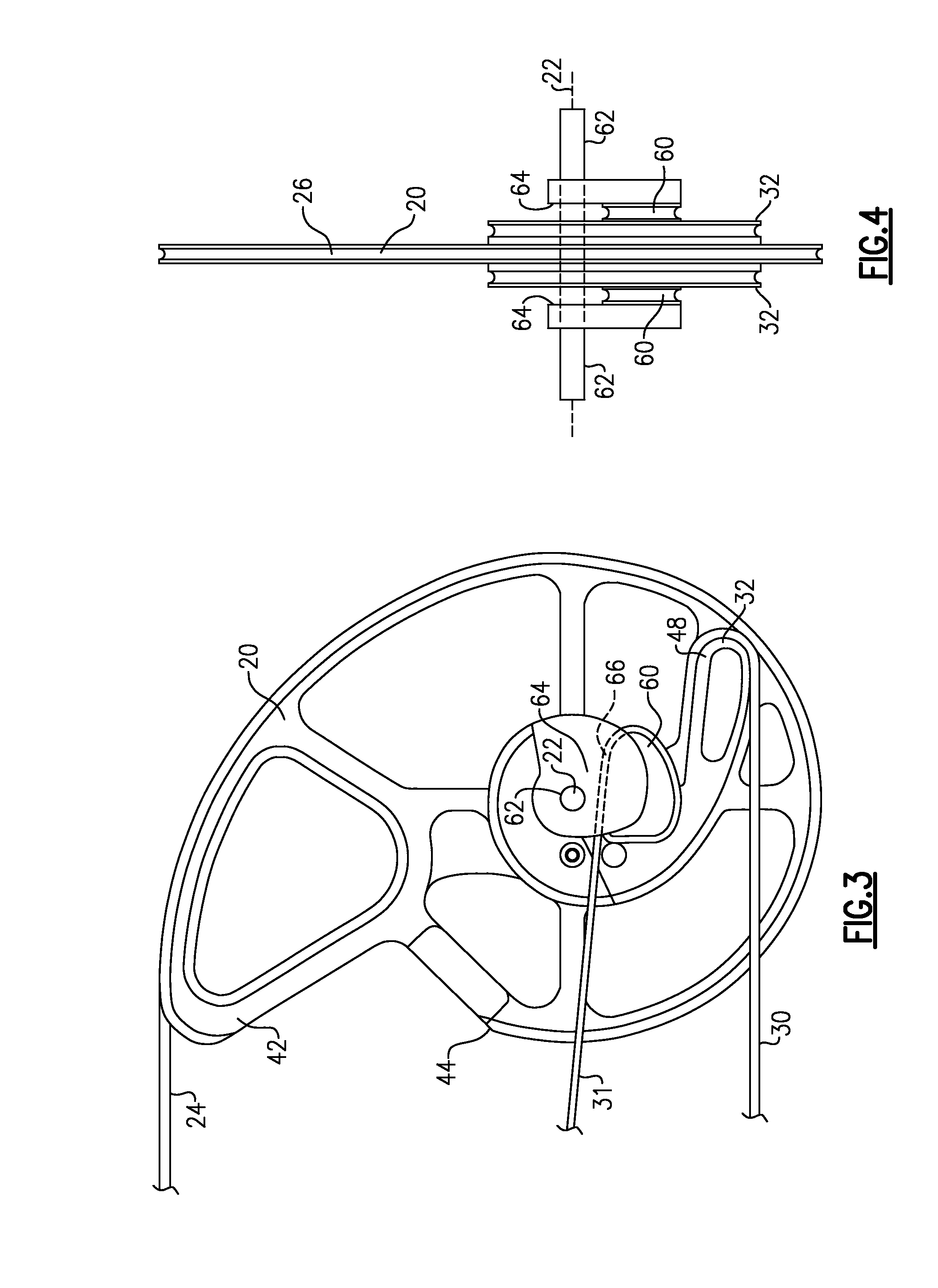

[0023]The compound bow has a riser or handle portion at its center with upper and lower power limbs or spring limb portions with inboard ends that are affixed onto at the upper and lower ends of the riser. The bow is considered in its normal, upright shooting orientation, as is conventional. There are upper and lower bowstring cam assemblies, e.g., bowstring cam 20, that are pivotally or rotationally attached at respective pivot axes to the outboard ends of the power limb members. A bow string 24 is attached to each bowstring cam 20 and rides in a peripheral groove or channel 26 in each of these cams, which groove is adapted to receive the bow string 24. Synchronizing pulleys are pivotally mounted on the riser near the ends. A continuous synchronizing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com