Micro-pore plate type electromagnetic separator

A technology of electromagnetic separation and micro-orifice plate, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of difficult automation, bulky quality, uneven magnetic field, etc., and achieve easy automation, low cost, and fast separation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

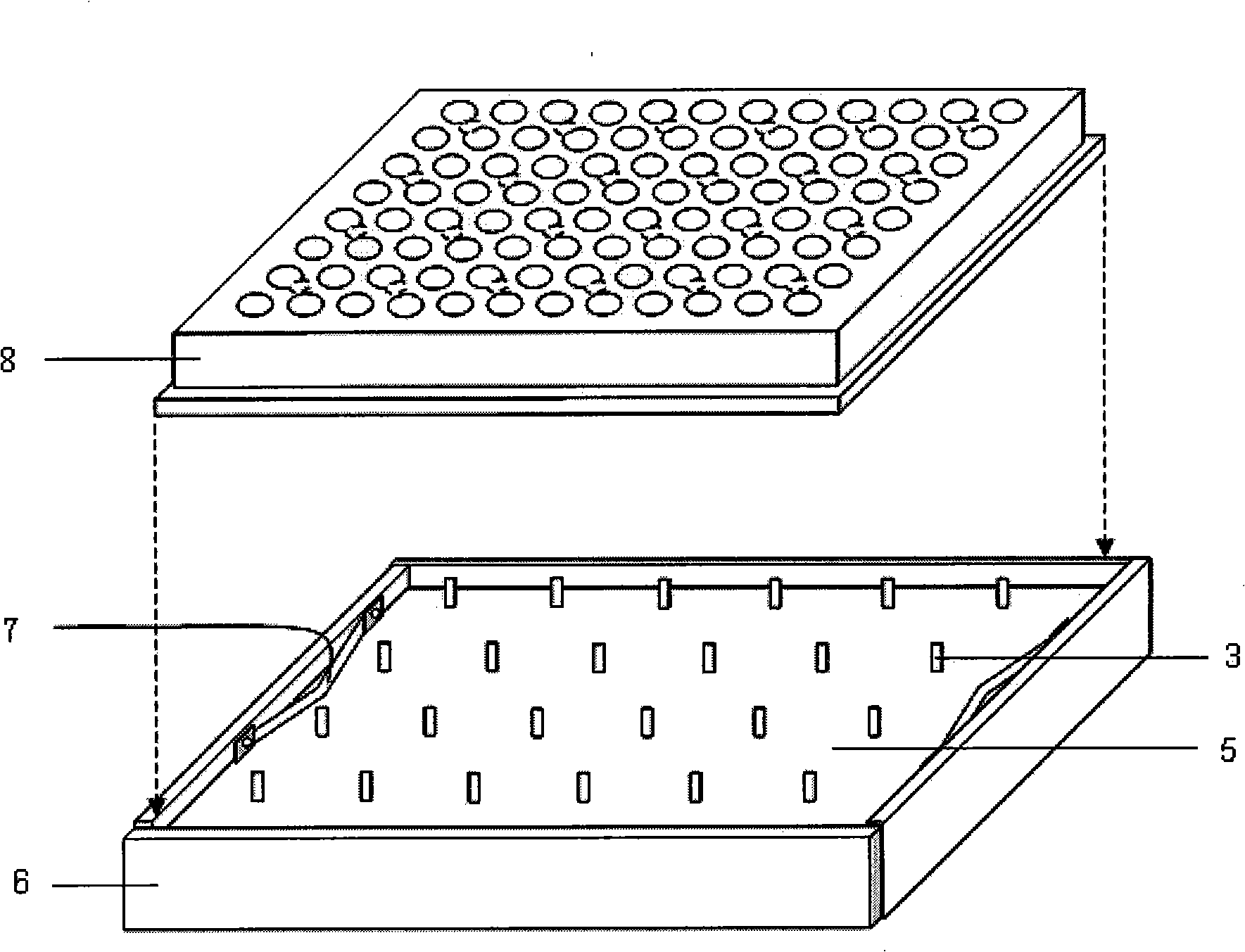

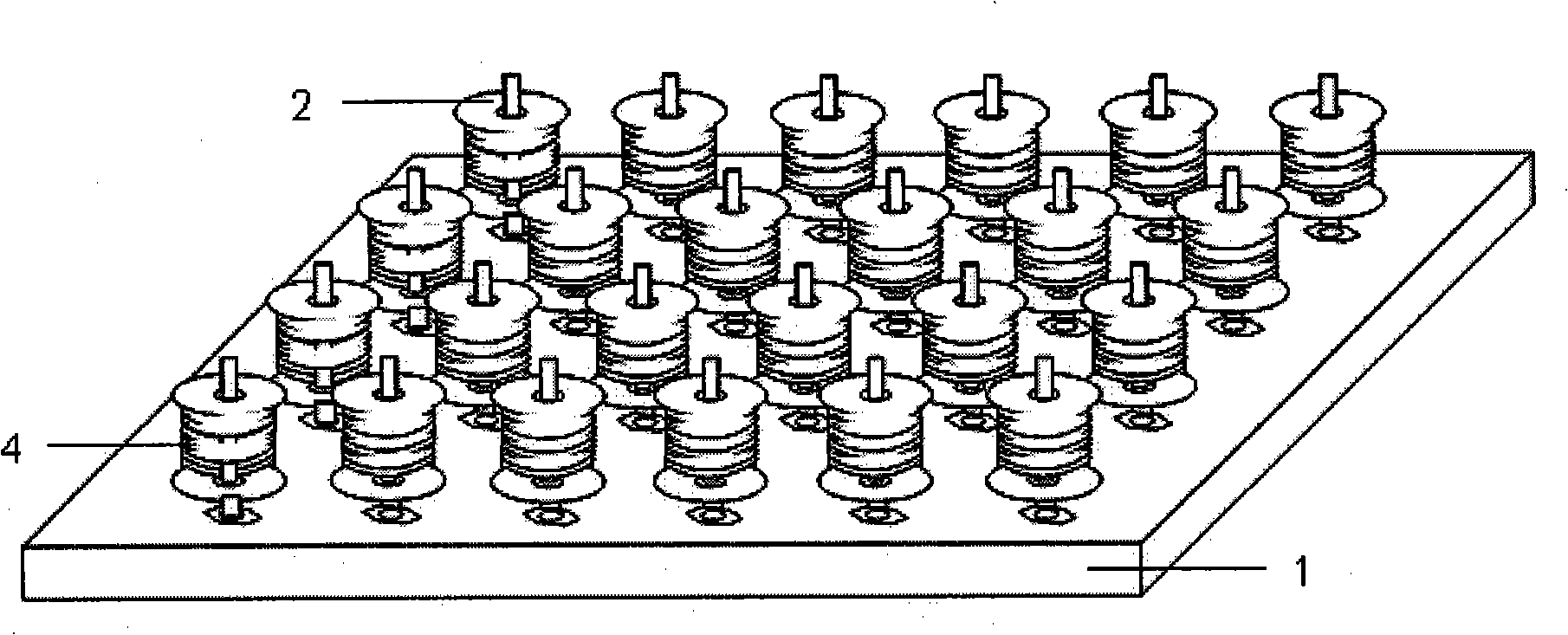

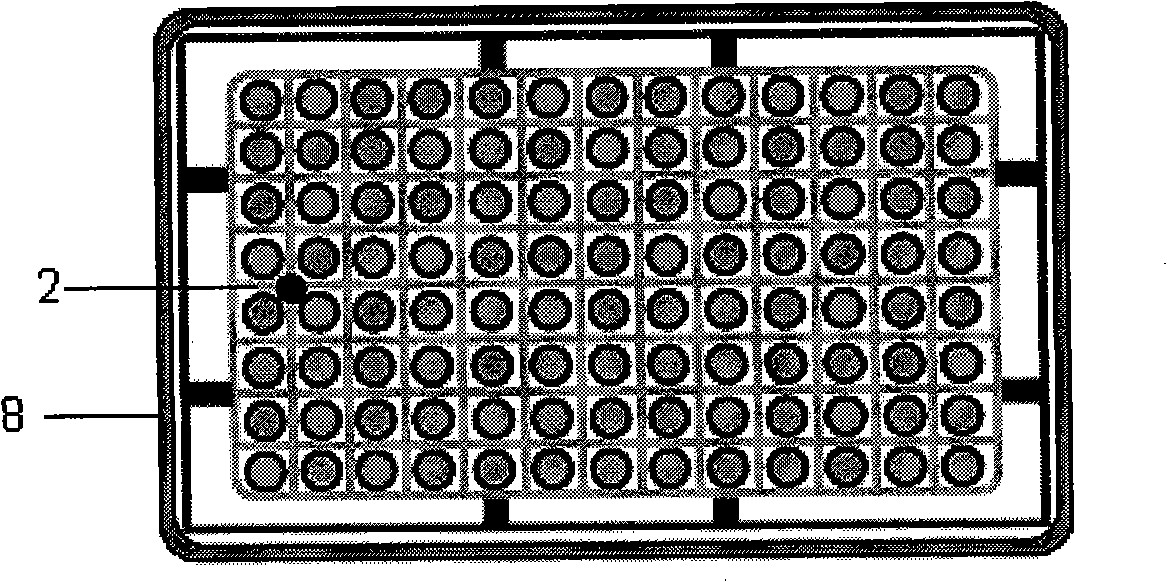

[0025] Such as figure 1 , figure 2 As shown, the present invention includes a tray 1, on which a group of electromagnet arrays made up of a plurality of small electromagnets 2 is arranged, and each small electromagnet 2 includes a magnetic core 3 and a magnetic core 3 surrounded by a A coil 4 wound with multiple turns of wire, and the two ends of the coil 4 are connected to a power supply. A cover plate 5 is arranged above the electromagnet array, and holes are opened on the cover plate 5 to allow corresponding small magnetic cores 3 , and a pair of retaining springs 7 are arranged in two corresponding frames 6 of the tray 1 . A microporous plate 8 is arranged on the top of the cover plate 5 , and the two sides of the microporous plate 8 are clamped under the two retaining springs 7 .

[0026] In the above-mentioned embodiment, the quantity of sma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com