Discrete material reinforcement composite foundation model pile, test device and test method

A technology of composite foundation and bulk materials, which is applied in foundation structure tests, foundation structure engineering, construction, etc., can solve the problems that the vertical bearing capacity of sandstone piles cannot be considered, and the pile-soil stress ratio of composite foundation is complex, etc., and achieve The effect of simple production, simple and reasonable conception, and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

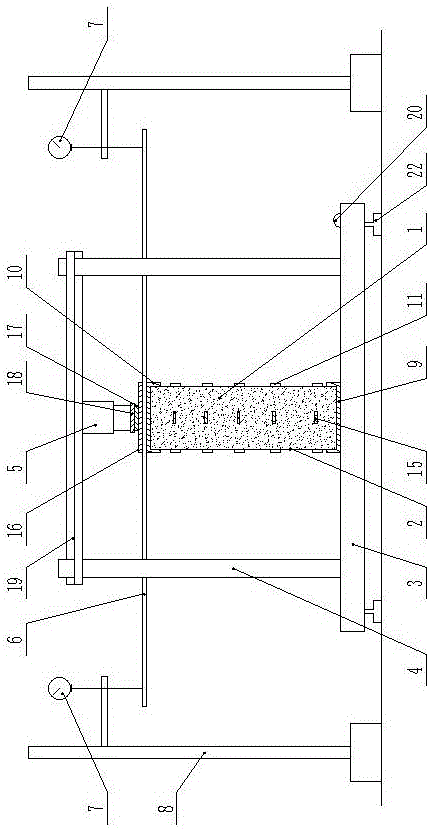

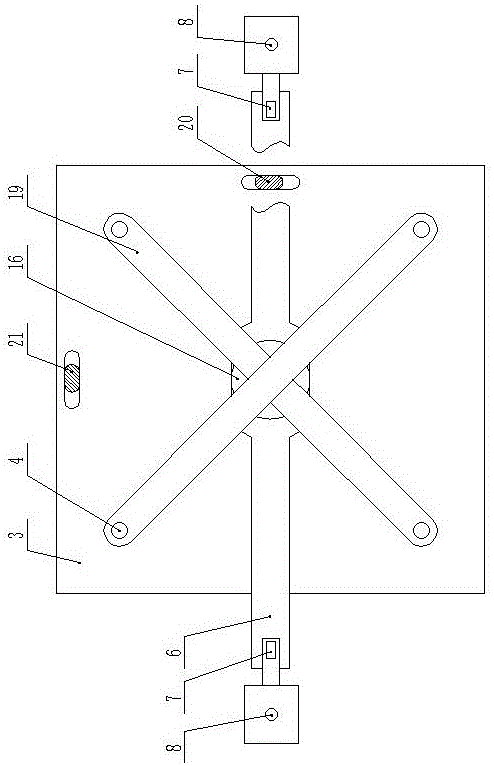

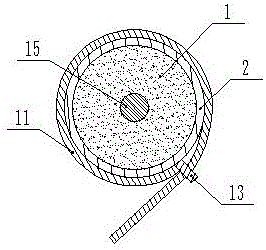

[0050] like Figure 1-Figure 6 As shown, a composite foundation model pile reinforced with bulk materials, the model pile includes a filling material 1 and a wrapping coil 2, the wrapping coil 2 is cylindrical, and it is rolled from a stepped thin plate. The highest section of the stepped thin plate is rolled up to form the innermost layer, and the rest of the stepped parts are rolled out in turn to form a wrapping coil 2 whose wall thickness gradually becomes thicker from top to bottom. The bottom of the wrapping coil 2 is set on a closed ring-shaped pile 9, the top is sheathed in the top-closed annular pile cap 10, and the filling material 1 is filled inside the cylinder formed by wrapping the roll material 2.

[0051] The manufacturing material of the wrapping coil 2 is cardboard, or plastic board, or geotextile.

[0052] The filling material 1 is sand.

[0053] A test device made of the above-mentioned bulk material reinforced composite foundation model pile, including a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com