Device and method for producing half-water gas by employing oxygen-enriched air

A technology of oxygen-enriched air and semi-water gas, which is applied in the manufacture of combustible gas and petroleum industry, etc., can solve the problems of low production of synthetic ammonia raw material gas, large consumption of raw coal and steam, save raw coal and steam consumption, increase production, The effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is further described below.

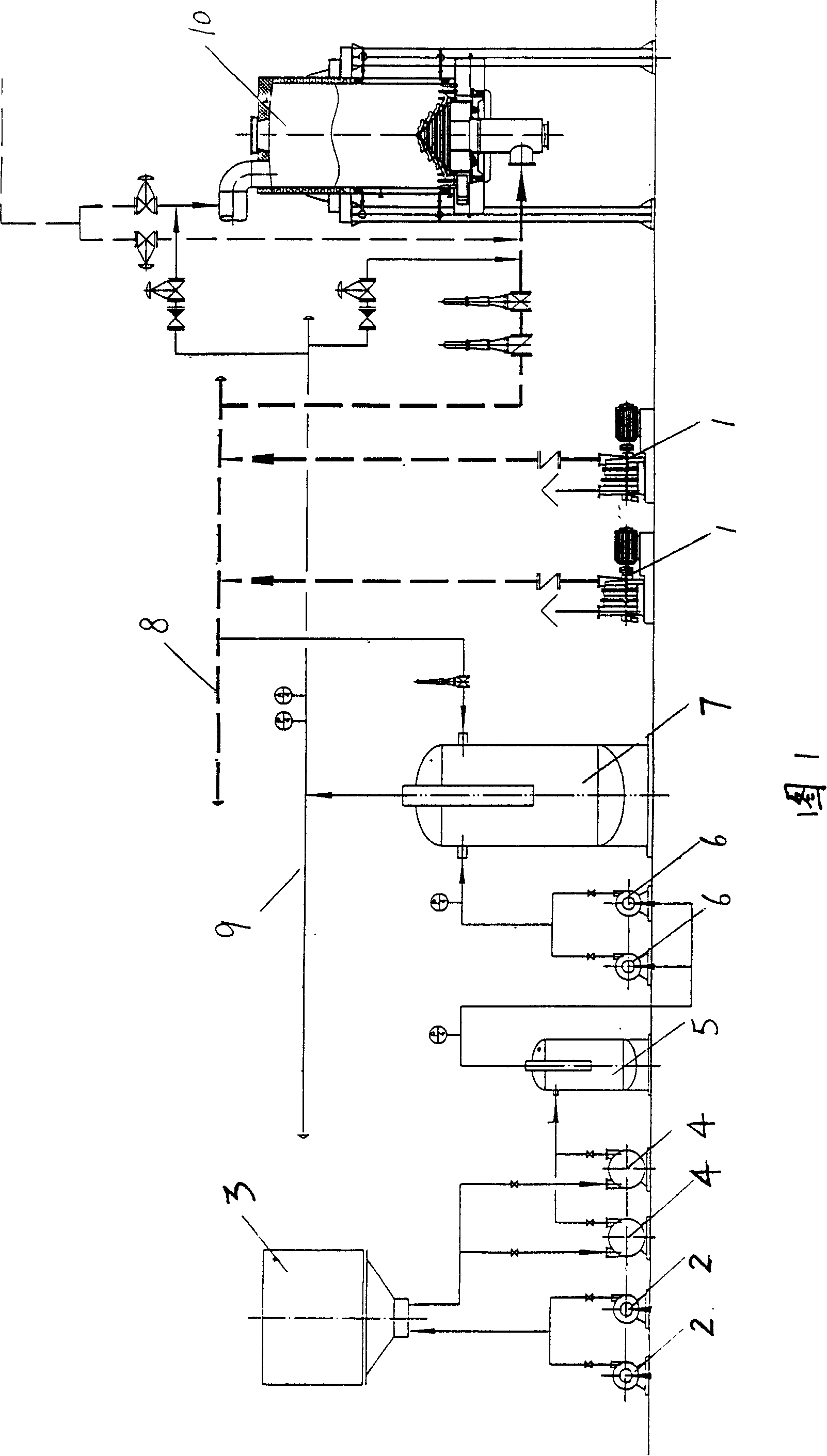

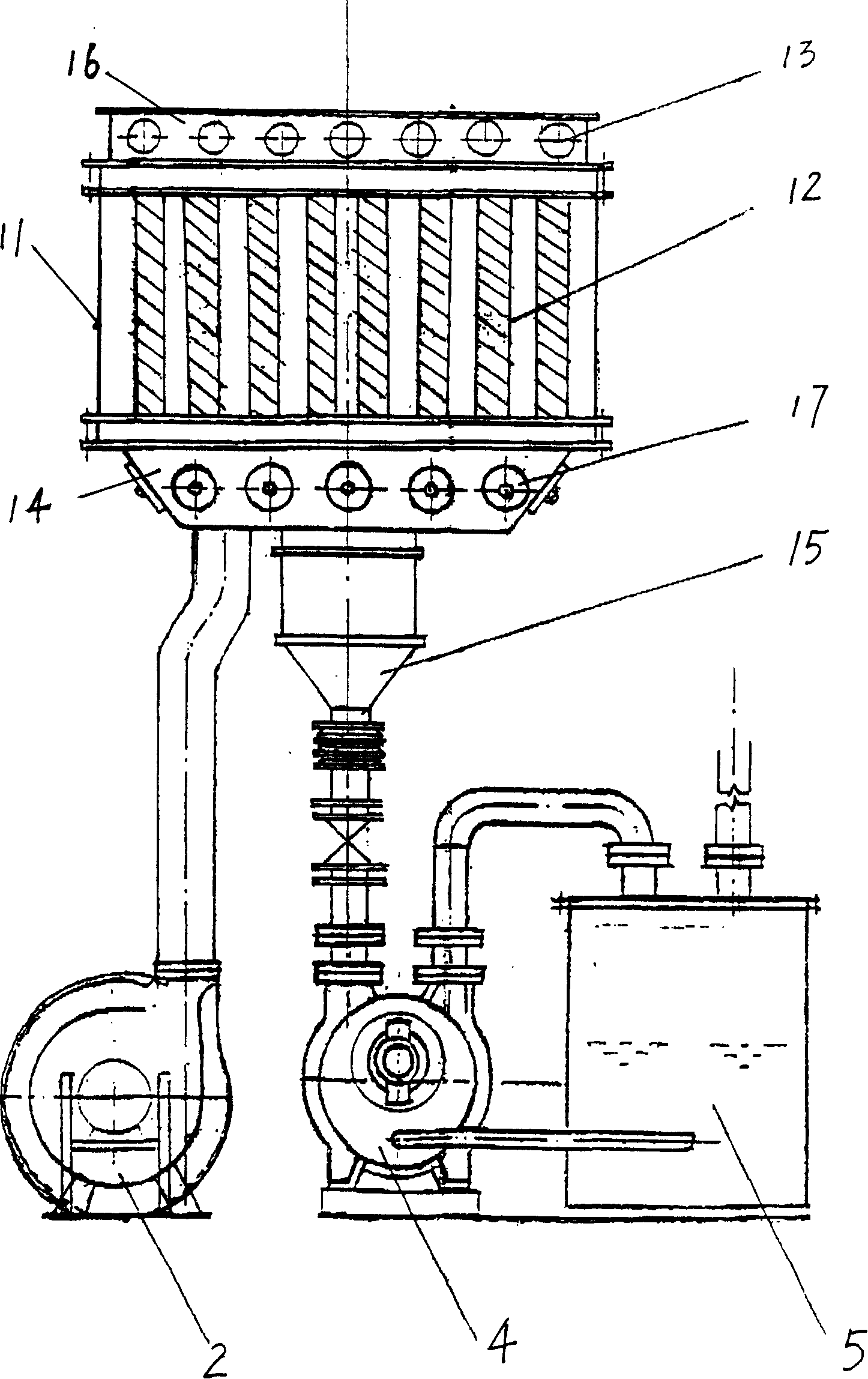

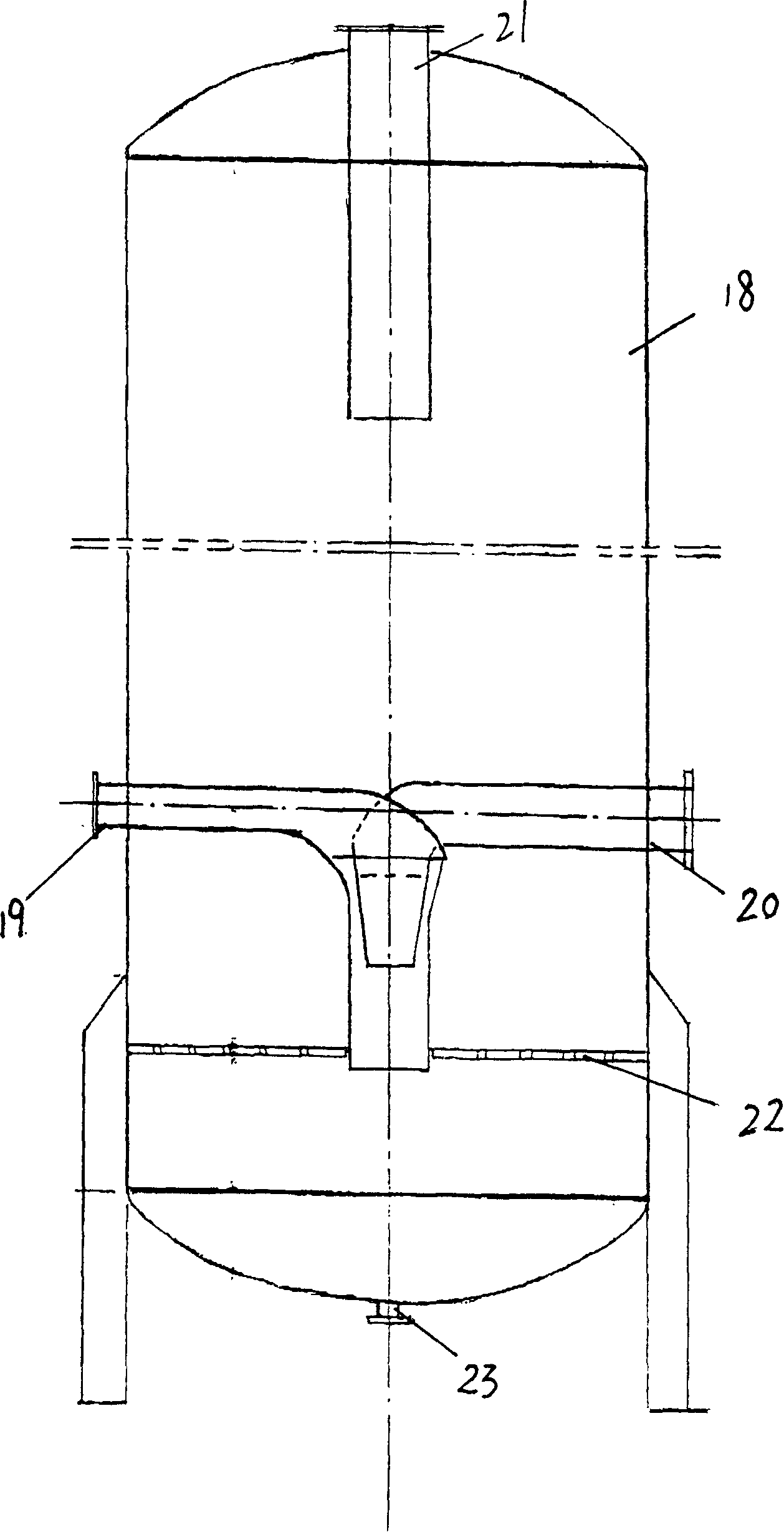

[0012] As can be seen from the figure, the device utilizing oxygen-enriched air to produce semi-water gas of the present invention comprises the following parts: air blower 2, air blower 2 is connected with the input end of oxygen-enriched generator 3, and the output end of oxygen-enriched generator 3 is connected with The input end of vacuum pump 4 is connected, and the output end of vacuum pump 4 is connected with the input end of gas-water separation tank 5, and the output end of gas-water separation tank 5 is connected with an input end of air mixing tank 7 by oxygen-enriched air blower 6, and air mixing The other input end of tank 7 is connected with common air pipeline 8, and the output end of air mixing tank 7 is connected with gas generator 10 through oxygen-enriched air main pipe 9. Ordinary air pipeline 8 can also be connected with air-making blower 1, and is used for blowing ordinary air into air mixing tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com