Coated fertilizer for inducing root growth and preparation method and application thereof

A technology for root growth and fertilizer, applied in the application, fertilizer form, fertilizer mixture and other directions, can solve the problems such as few nutrient types, it is difficult to meet the needs of crop growth and development, the granulation process is complicated, and the slow release performance cannot be maximized. Achieve the effect of promoting photosynthesis, improving crop quality, and improving physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

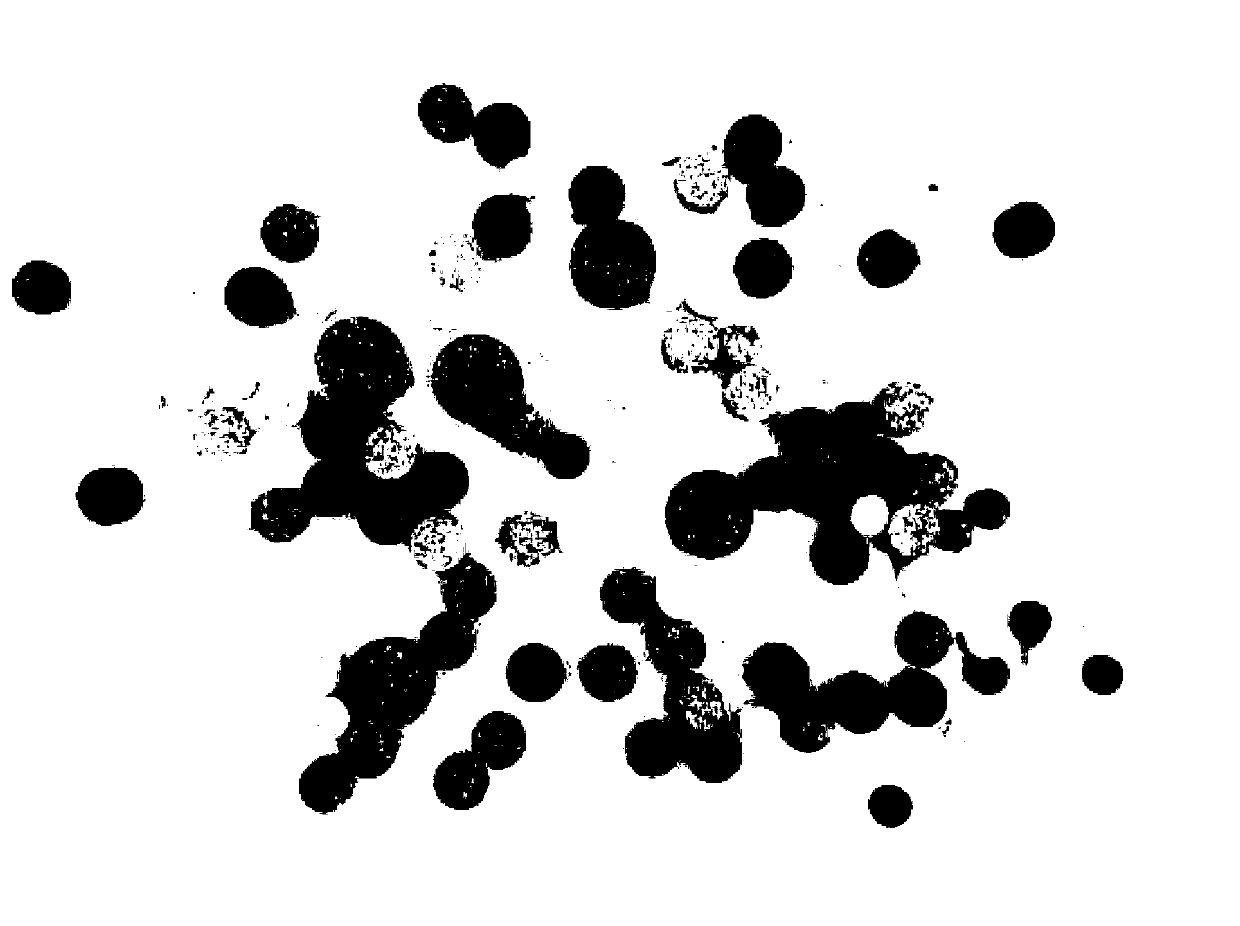

Image

Examples

Embodiment 1

[0052] Prepare the coated fertilizer that induces root growth, and the raw material components are as follows:

[0053] The total ingredients of the fertilizer core are 1000g: dry base 50g, compound amino acid powder (amino acid content ≥ 46wt%) 50g, potassium fulvic acid 50g, molasses powder 50g, potassium nitrate 150g, potassium sulfate 100g, potassium dihydrogen phosphate 150g, urea 180g, Calcium carbonate 50g, magnesium sulfate heptahydrate 100g, borax 20g, zinc sulfate heptahydrate 20g, talcum powder 30g.

[0054] The coating layer contains the following components: carboxymethyl cellulose aqueous solution (2%wt) 150g, DA-62g, fulvic acid 10g, cellulose 150g, sodium alginate solution (10%wt) 150g, saturated calcium chloride solution 100g.

[0055] The preparation method is as follows:

[0056] (1) Grinding and mixing: dry matrix, compound amino acid powder, potassium nitrate, potassium sulfate, potassium dihydrogen phosphate, urea, calcium carbonate, magnesium sulfate h...

Embodiment 2

[0062] Prepare the coated fertilizer that induces root growth, and the raw material components are as follows:

[0063] The total ingredients of the fertilizer core are 1000g: dry base 50g, compound amino acid powder (amino acid content ≥ 98wt%) 50g, potassium fulvic acid 50g, molasses powder 50g, potassium dihydrogen phosphate 50g, urea 500g, calcium sulfate 50g, magnesium sulfate heptahydrate 100g, 50g of borax, 20g of zinc sulfate heptahydrate, 30g of talcum powder.

[0064] The coating layer contains the following components: 150g of hydroxyethyl cellulose aqueous solution (5wt%), 1g of sodium nitrophenolate, 10g of fulvic acid, 150g of cellulose, 150g of sodium alginate solution (5wt%), saturated calcium chloride solution 100g.

[0065] The preparation method is as follows:

[0066] (1) Grinding and mixing: Mix dry matrix, potassium dihydrogen phosphate, urea, calcium sulfate, magnesium sulfate heptahydrate, borax, zinc sulfate heptahydrate, potassium fulvic acid, compo...

Embodiment 3

[0072] Prepare the coated fertilizer that induces root growth, and the raw material components are as follows:

[0073] The total ingredients of the fertilizer core are 1000g: dry base 75g, compound amino acid powder (amino acid content ≥ 46wt%) 25g, potassium fulvic acid 25g, molasses powder 75g, potassium nitrate 200g, potassium dihydrogen phosphate 170g, urea 200g, calcium sulfate 60g, Magnesium sulfate heptahydrate 100g, borax 20g, zinc sulfate heptahydrate 20g, talcum powder 30g.

[0074] The coating layer contains the following components: polyvinyl alcohol aqueous solution (3wt%) 200g, naphthaleneacetic acid 2g, fulvic acid 20g, bentonite 200g, sodium alginate solution (8wt%) 200g, saturated calcium chloride solution 100g.

[0075] The preparation method is as follows:

[0076] (1) Pulverization: Mix dry matrix, potassium nitrate, potassium dihydrogen phosphate, urea, calcium sulfate, magnesium sulfate heptahydrate, borax, zinc sulfate heptahydrate, potassium fulvic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com