Prodn method of high azote, high potassium and sulfenyl 3-element compound fertilizer

A ternary compound fertilizer and production method technology, applied in the direction of urea compound fertilizer, nitrogen fertilizer, potash fertilizer, etc., can solve the problems of failing to meet product quality requirements, excessive chloride ion content in finished products, unstable production increase effect, etc., and achieve good results, The effect of reducing the amount of chemical fertilizers and implementing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

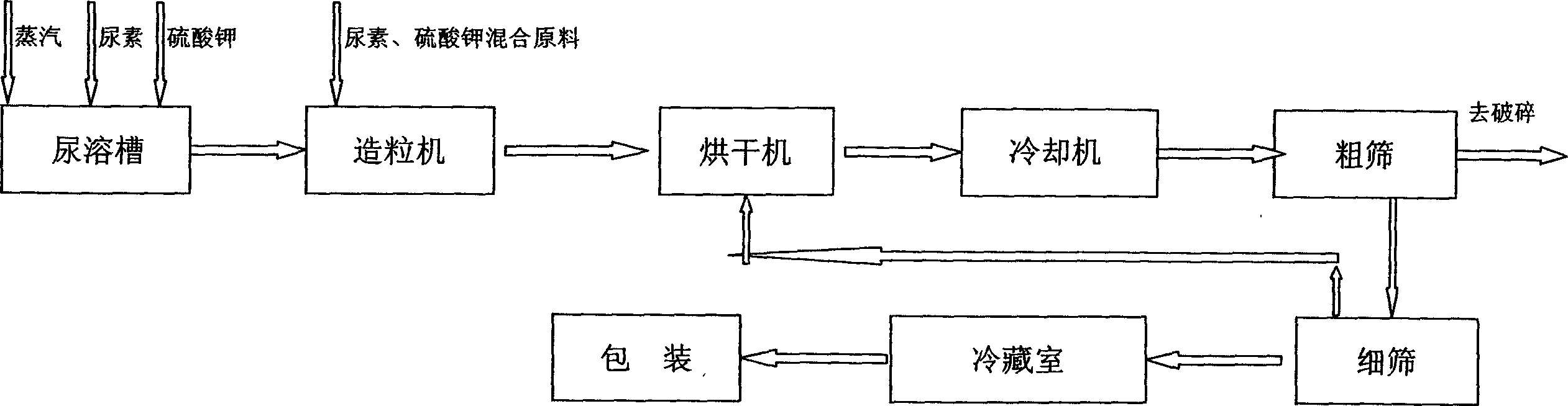

[0025] Such as figure 2

[0026] The present invention can get raw material by the proportioning of following percentage by weight:

[0027] Potassium sulfate: 18.1%

[0028] 12-18-15 compound fertilizer: 57%

[0030] Urea: 21.25%.

[0031] The production method of high-nitrogen and high-potassium sulfur-based ternary compound fertilizer. The steps involved are:

[0032] 1) In the urine dissolving tank, urea accounting for 15% of the total finished product and potassium sulfate accounting for 5% of the total finished product are melted by steam; the melted liquid is evenly sprayed on the material in the granulator through a metering pump superior. The temperature in the urine dissolving tank is controlled at 120°C. If the temperature is too high, it will easily cause the volatilization of nitrogen and the production of biuret. If the temperature is too low, it is easy to block the pipeline of the urine solution pump and the nozzle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com