Liquid chelated fertilizer production device

A production device, liquid technology, applied in the direction of fertilization device, liquid fertilizer, fertilizer mixture, etc., can solve the problems of pipeline blockage, stirring effect, easy generation of dust, etc., to achieve easy cleaning and regular maintenance and replacement, avoid dust, production and operation costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

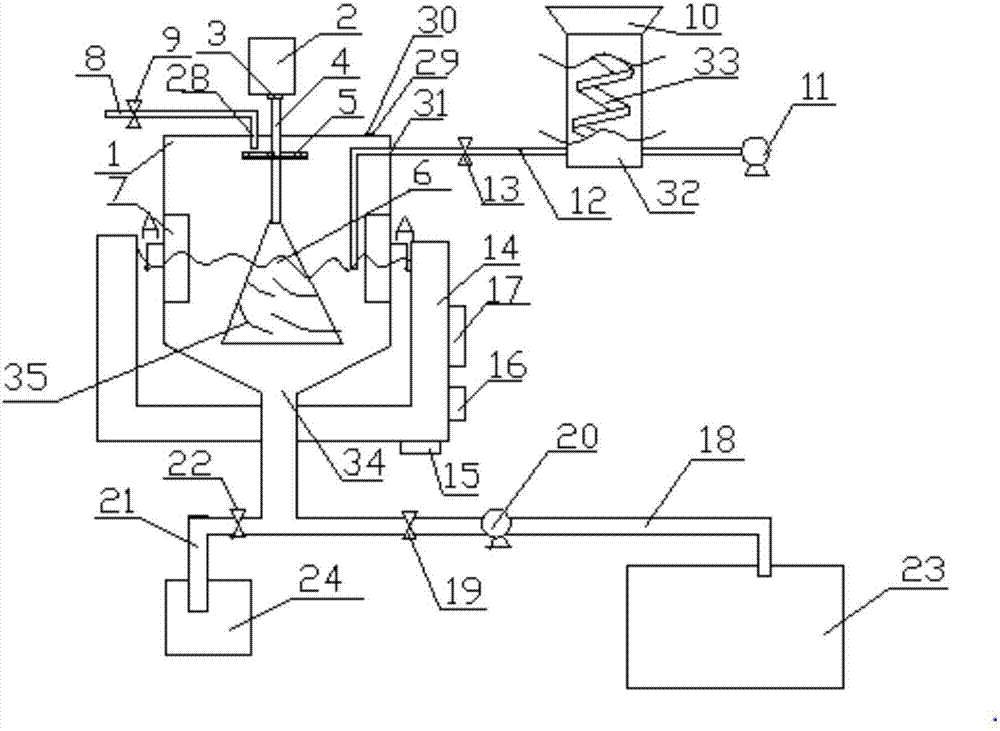

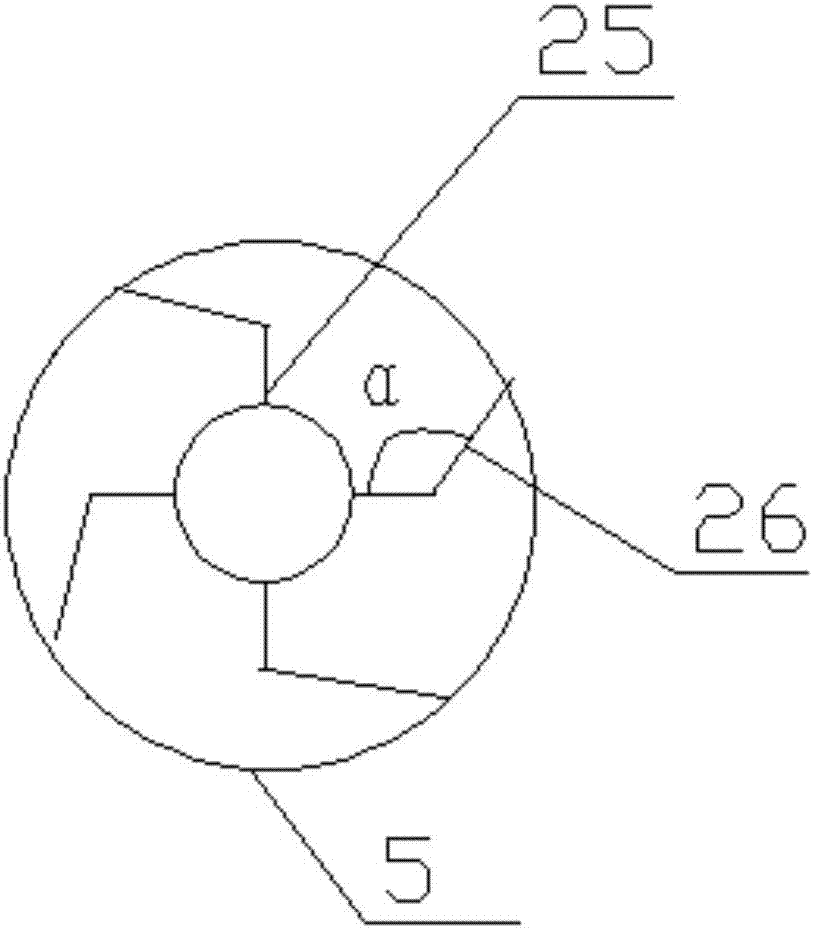

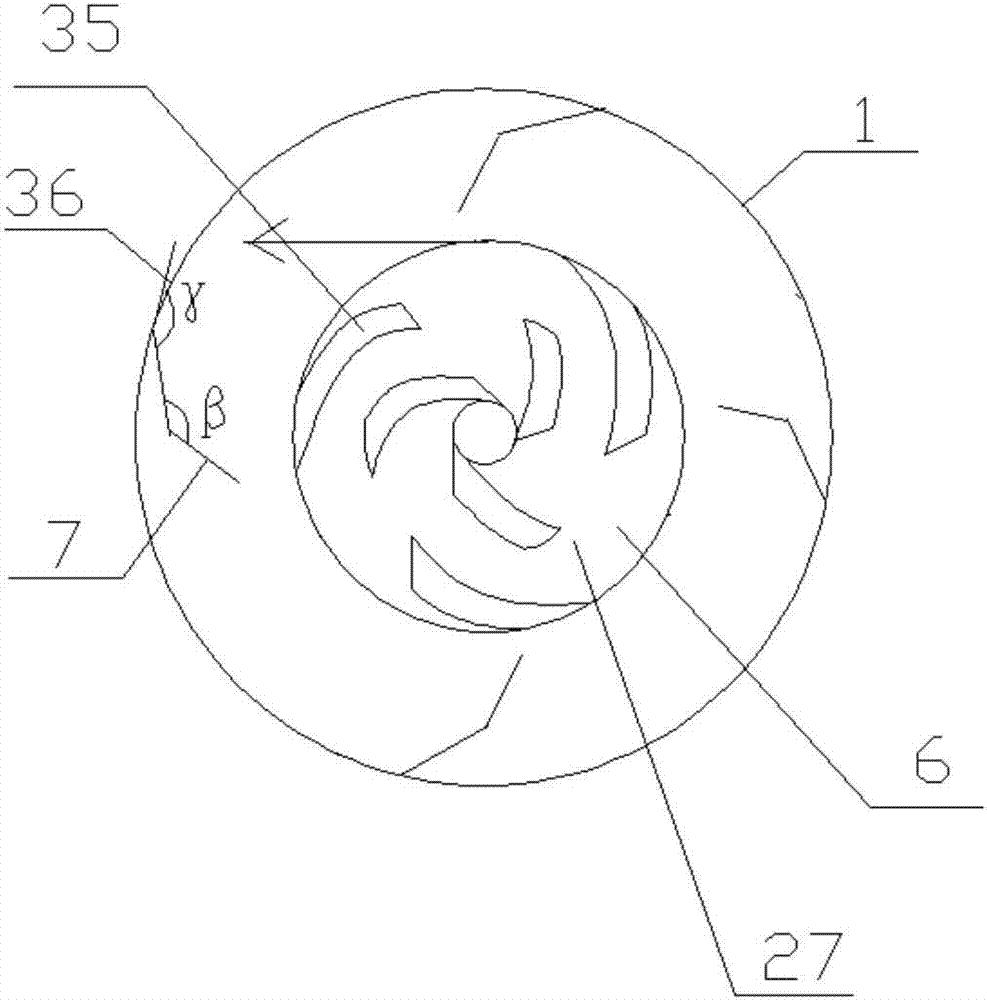

Embodiment 1

[0026]The main structure of the liquid chelate fertilizer production device involved in this embodiment includes a reaction kettle 1, a frequency conversion motor 2, a shaft coupling 3, a stirring shaft 4, a rotating disk 5, an agitator 6, a first baffle plate 7, a water inlet pipe 8, Water inlet valve 9, feed device 10, fan 11, feed pipe 12, feed valve 13, water bath 14, heating rod 15, temperature controller 16, temperature display 17, discharge pipe 18, discharge valve 19, Discharging pump 20, drain pipe 21, drain valve 22, material receiving device 23 and sewage collecting device 24, the reaction kettle 1 made of single-layer glass is a vertical cylindrical cavity structure, and the reactor 1 is vertically installed Frequency conversion motor 2, a stirring shaft 4 is vertically arranged directly below the frequency conversion motor 2, the frequency conversion motor 2 is connected to the top of the stirring shaft 4 through a coupling 3, the stirring shaft 4 is driven by the ...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that the reaction kettle 1 is double-glazed, and steam heating is used, which is suitable for pilot plant and large-scale production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com