Purification method of impurity iodine in silicon tetrafluoride gas

A technology of silicon tetrafluoride and fluorine-containing gas, which is applied in the direction of silicon halide compounds, halosilanes, etc., and can solve the problems that there is no technical solution for the purification of silicon tetrafluoride impurity iodine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

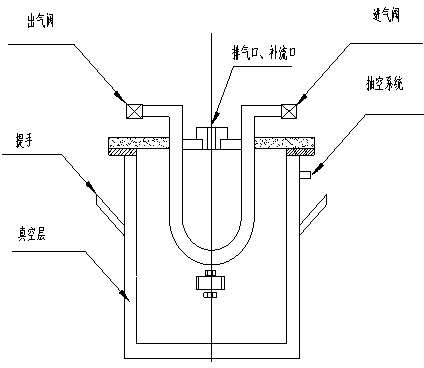

Image

Examples

Embodiment 1

[0021] A factory is a chemical enterprise that handles phosphate rock by wet method, and a large amount of fluorine-containing gas is produced in the process of treating phosphate rock with sulfuric acid. The collected gas is treated with the method of the present invention to produce high purity silicon tetrafluoride. First, collect the gas containing hydrogen fluoride and silicon tetrafluoride produced in the process of wet treatment of phosphate rock, and introduce the gas containing fluorine into a concentrated sulfuric acid with a mass fraction of 85% to 98% and a silicon dioxide content of ≥95%, fine In the reactor with quartz sand whose density is less than 0.3mm, the mass ratio of quartz sand and concentrated sulfuric acid added is 2:10; hydrogen fluoride in fluorine-containing gas is converted into silicon tetrafluoride gas at a temperature of 45°C to 130°C; Then introduce silicon tetrafluoride gas into the purification tank, and use 98% concentrated sulfuric acid or ...

Embodiment 2

[0023] A factory mixes fluosilicic acid and concentrated sulfuric acid and heats it to produce gaseous compounds, then introduces the gaseous compounds into a container filled with concentrated sulfuric acid, removes impurities such as HF and moisture, and obtains silicon tetrafluoride gas; use the same method as in Example 1 A method for processing the collected gas to produce high-purity silicon tetrafluoride gas SiF 4 Mass fraction ≥ 99.9%, of which iodine content is less than 10 -6 (1ppm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com