Soil heavy mental repairing agent and preparation method and application thereof

A technology of heavy metals and remediation agents, applied in the field of environmental pollution control, can solve problems such as single remediation technology, high pollutant content, and large polluted area, and achieve the effects of inhibiting crop absorption, strong environmental adaptability, and high survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

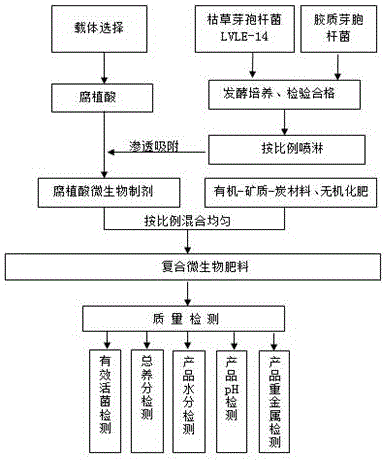

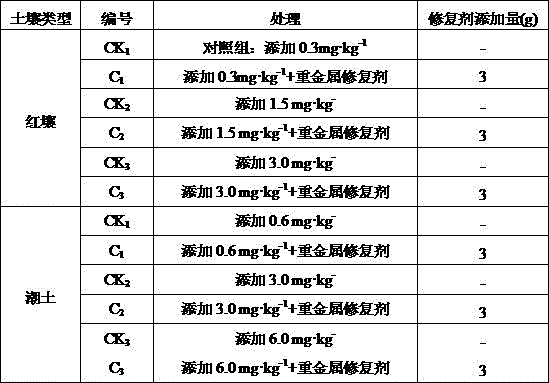

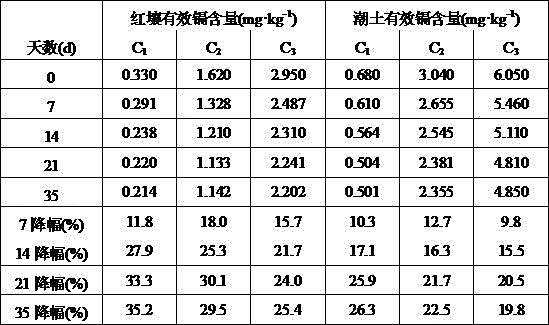

[0041] The preparation method of the soil heavy metal remediation agent of the present embodiment is as follows:

[0042] (1) Microbial agent preparation: Bacillus subtilis LVLE-14 and Bacillus mucilaginosus Krassilnikov were fermented separately, then adsorbed with humic acid, in parts by weight, according to the ratio of 3:5 mix, pulverize;

[0043] (2) Preparation of raw material mixture: in parts by weight, crushed corn stalks (passed through a 80-100 mesh sieve) and ashed rice husk powder, attapulgite powder and calcium magnesium phosphate fertilizer according to the ratio of 3:2:2:2 The ratio is mixed and crushed.

[0044] (3) Preparation of compound microbial fertilizer: Stir the microbial agent obtained in step (1) and the raw material mixture obtained in step (2) evenly, then pulverize to obtain a compound microbial fertilizer. The weight portion of the composite microbial bacterial agent in the finished composite microbial fertilizer is 1 part.

[0045] Applicatio...

Embodiment 2

[0047] The preparation method of the soil heavy metal remediation agent of the present embodiment is as follows:

[0048] (1) Microbial agent preparation: ferment Bacillus subtilis LVLE-14, Bacillus colioids, strains separately, then adsorb with humic acid, mix and pulverize according to the ratio of 3:5 in parts by weight;

[0049] (2) Preparation of raw material mixture: in parts by weight, crushed mushroom dregs (passed through a 80-100 mesh sieve) and carbonized rice straw, sepiolite and silicon-calcium fertilizer were mixed in a ratio of 3:3:1.5:1.5, smash.

[0050] (3) Preparation of compound microbial fertilizer: Stir the microbial agent obtained in step (1) and the raw material mixture obtained in step (2) evenly, then pulverize to obtain a compound microbial fertilizer. The weight portion of the composite microbial bacterial agent in the finished composite microbial fertilizer is 1 part.

[0051] Application method: 100 kg per mu. If it is a dry field, evenly spread...

Embodiment 3

[0053] The preparation method of the soil heavy metal remediation agent of the present embodiment is as follows:

[0054] (1) Microbial agent preparation: ferment Bacillus subtilis LVLE-14, Bacillus colioids, strains separately, then adsorb with humic acid, mix according to the ratio of 4:5 in parts by weight, and pulverize;

[0055] (2) Preparation of raw material mixture: in parts by weight, crushed corn stalks (passed through a 80-100 mesh sieve) and shell charcoal, bentonite and phosphate rock powder are mixed in a ratio of 3.5:2:1.5:1.5, and crushed.

[0056] (3) Preparation of compound microbial fertilizer: Stir the microbial agent obtained in step (1) and the raw material mixture obtained in step (2) evenly, then pulverize to obtain a compound microbial fertilizer. The weight portion of the composite microbial bacterial agent in the finished composite microbial fertilizer is 1.5 parts.

[0057] Application method: 120 kg per mu. If it is a dry field, spread it evenly o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com