Aquaculture water circulation purification method and device

A purification device and water circulation technology, applied in chemical instruments and methods, fish farming, water/sewage multi-stage treatment, etc. The effect of small pipe diameter, efficient decomposition and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

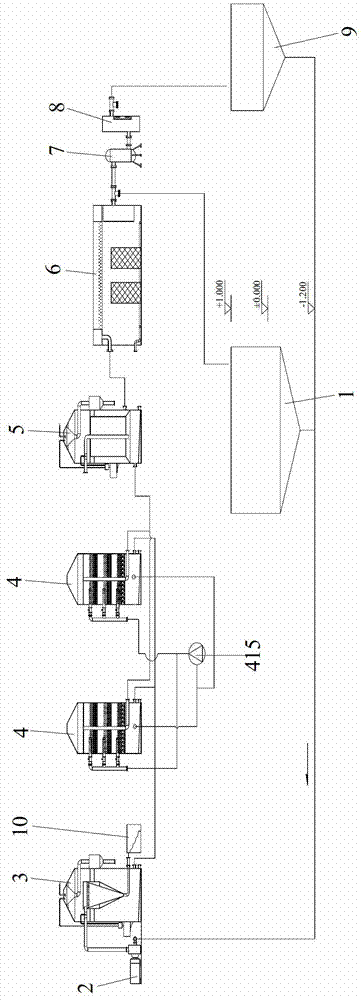

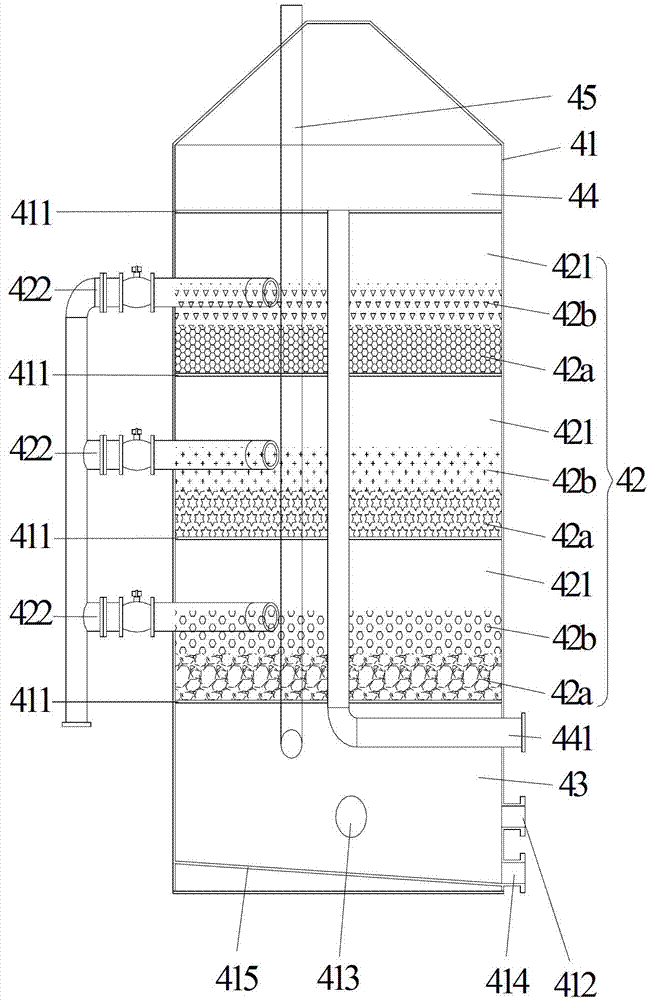

Method used

Image

Examples

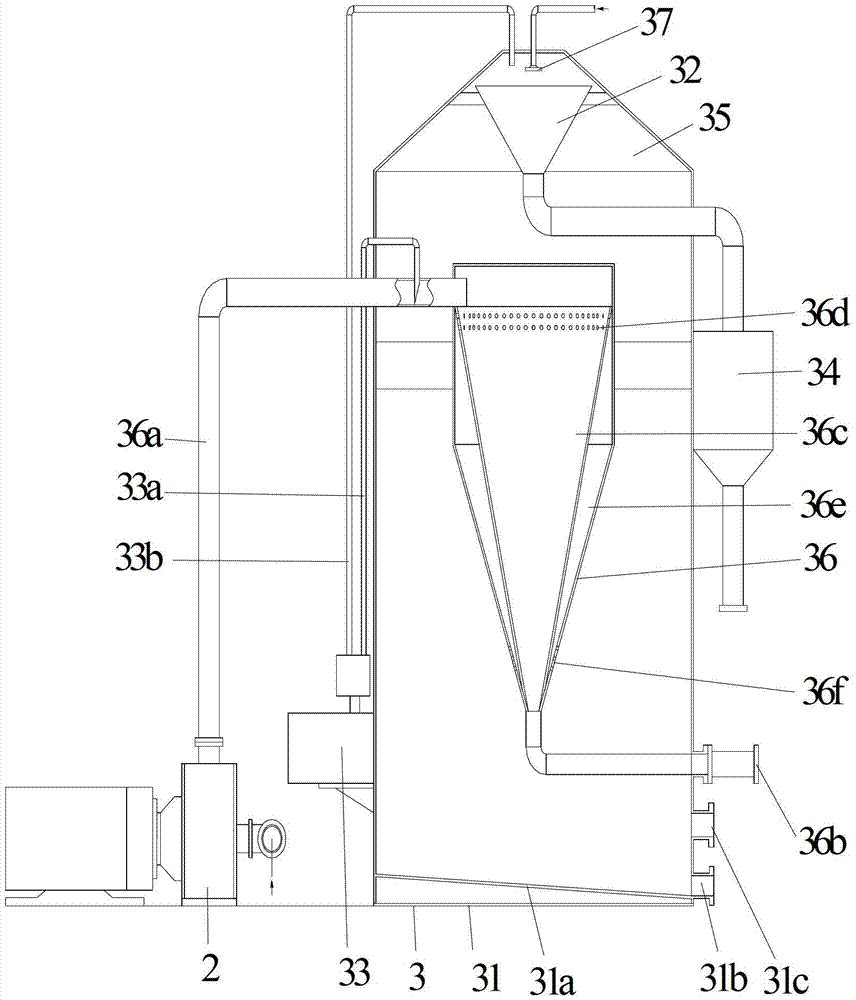

no. 3 example

[0059] The present invention may also have a third embodiment. The difference between this embodiment and the above-mentioned first embodiment is only that the inner cone 36c may not be provided in the swirl reactor 36, and the water outlet 36f may be directly arranged at The upper end of the swirl reactor 36, the outlet 36f is connected to the inner cavity of the shell 31, after the aquaculture water enters the swirl reactor 36, most of the aquaculture water passes through the outlet 36f Flowing into the inner cavity of the shell 31 can also achieve the purpose of protein separation.

no. 4 example

[0060] The present invention may also have a fourth embodiment. The difference between this embodiment and the above-mentioned first embodiment is only that: the aquaculture water treated by the aeration tank 6 directly overflows into the aquaculture pond 1, and the The breeding pond 1, the circulating water pump 2, the protein separator 3, the biomechanical filter 4, the disinfection processor 5, the aeration tank 6 and the solid-liquid separator 10 form a semi-closed full-cycle breeding water treatment system. This way can also achieve the purpose of aquaculture water recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com