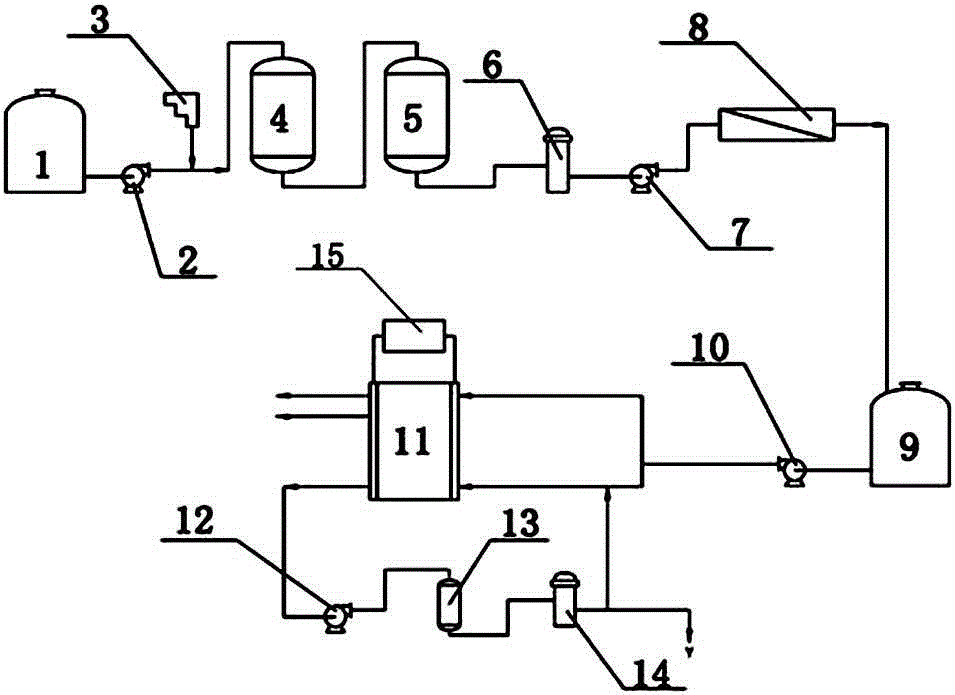

Ultra-pure water preparation system and method capable of preventing electrodeionization device from scaling

A technology for electrodeionization and preparation systems, applied in chemical instruments and methods, non-polluting water treatment, multi-stage water/sewage treatment, etc., can solve problems such as uneven distribution, increased fresh water inlet pressure, high operating voltage, etc., to reduce Investment and operating costs, simplification of the reverse osmosis process, and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: A microelectronics company uses the electro-deionization process to prepare ultrapure water. The raw water is tap water, which is boosted by a raw water booster pump and transported into a mechanical filter with a flow rate of 4.0m 3 / h, the pressure reaches above 0.3MPa; the water inlet pipe is connected to the metering pump, and ST flocculant is added at a dosage of 0.3-0.8mg / L, and PAC flocculant is added at a dosage of 1.5-3.0mg / L. The diameter of the mechanical filter is 800mm, and it is filled with anthracite and quartz sand filter materials. After filtering to remove suspended solids and colloids in the water, the water enters the activated carbon filter. The activated carbon filter has a diameter of 700mm and is filled with shell-type activated carbon, which is used to absorb organic matter and residual chlorine in water. The water absorbed by the activated carbon filter enters the precision filter to further remove particulate impurities in the water...

Embodiment 2

[0042] Example 2: A pharmaceutical company prepares ultra-pure water by electro-deionization process, and the raw water is also tap water, which is boosted by a raw water booster pump and transported into a mechanical filter with a flow rate of 8.0m 3 / h, the pressure reaches above 0.3MPa. The water inlet pipe is connected to the metering pump, and ST flocculant is added at a dosage of 0.5-1.5mg / L. The diameter of the mechanical filter is 1200mm, and it is filled with anthracite and quartz sand filter materials. After filtering to remove suspended solids and colloids in the water, the water enters the activated carbon filter. The activated carbon filter has a diameter of 1000mm and is filled with shell-type activated carbon, which is used to absorb organic matter and residual chlorine in water. The water absorbed by the activated carbon filter enters the precision filter to further remove particulate impurities in the water. The diameter of the precision filter is 250mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com