Regulating valve integral self-protection sealing surface structure

An integral, self-protecting technology, applied in the field of self-protecting sealing surface structure of regulating valve and integral self-protecting sealing surface structure of regulating valve, can solve the problem of frequent repair or replacement of valve core sealing surface and easy damage to valve core sealing surface , increase maintenance costs and other issues, to achieve the effect of simple structure, easy replacement and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

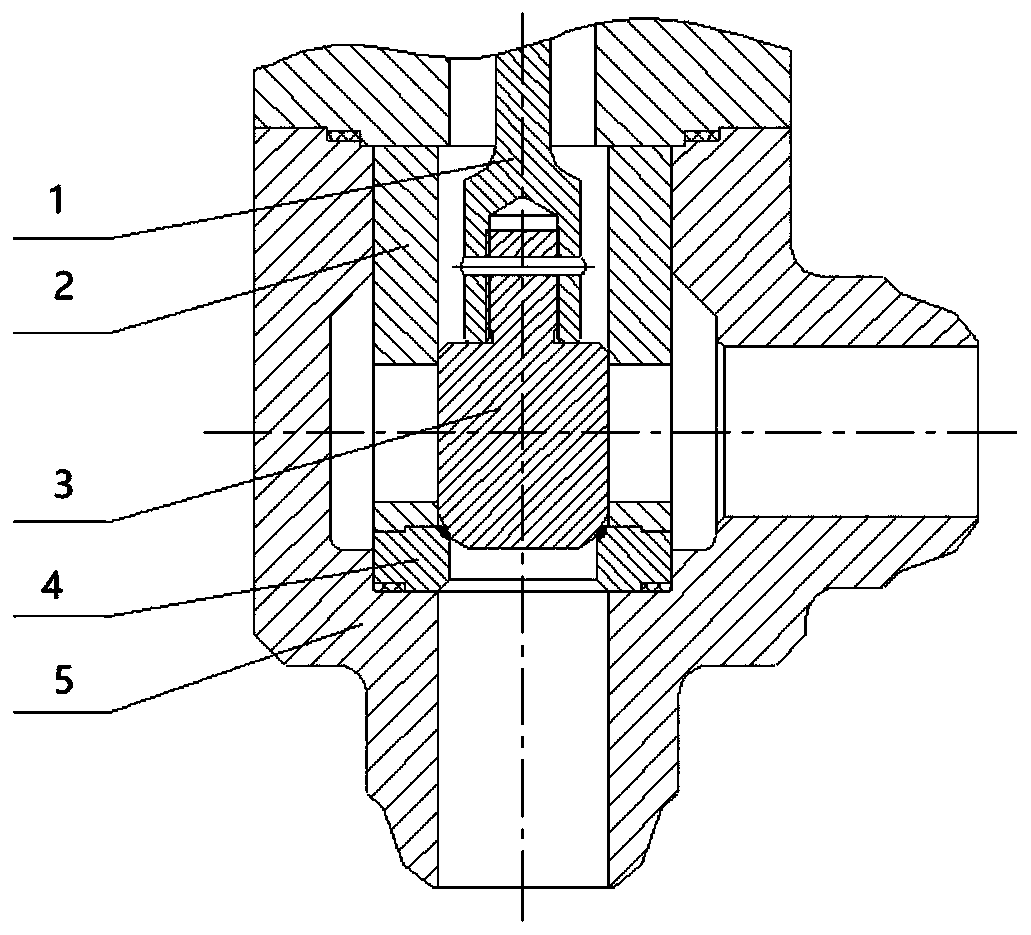

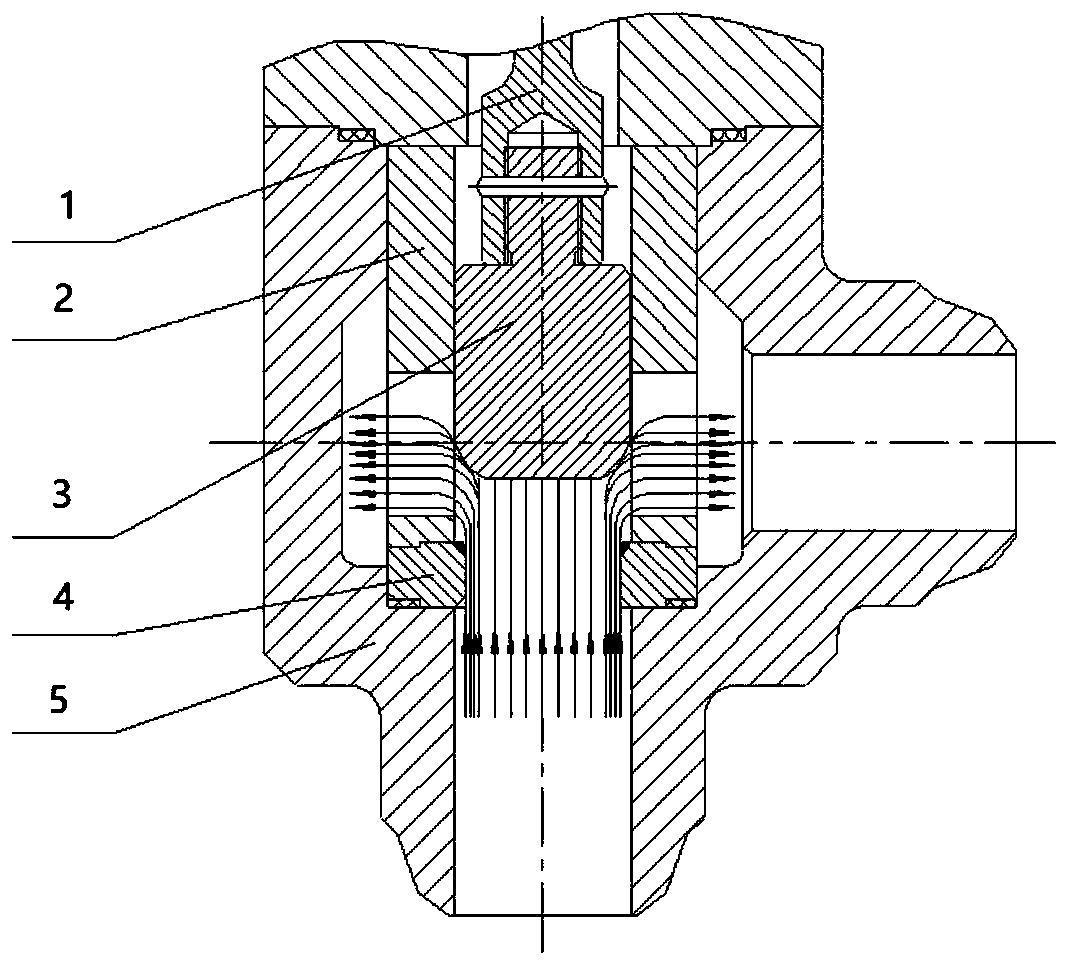

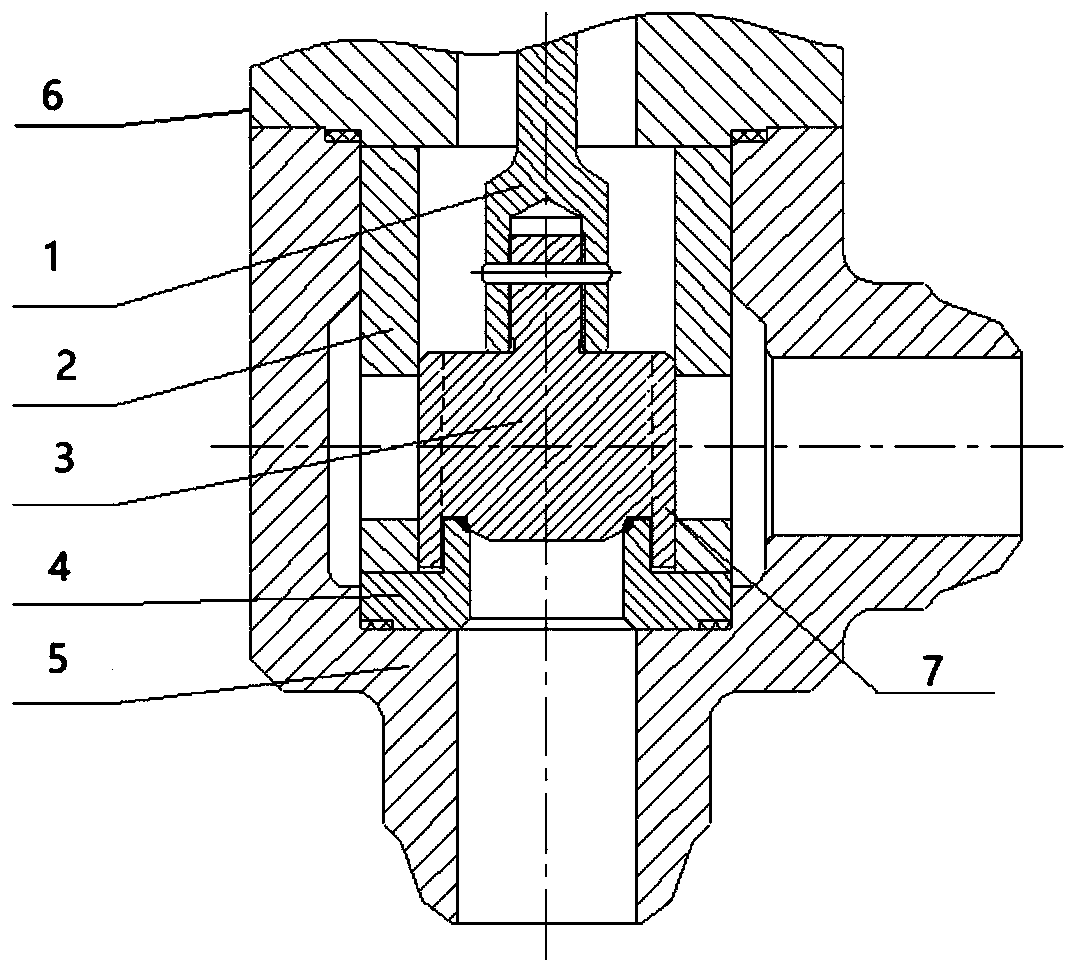

[0015] like image 3 As shown, an integral self-protecting sealing surface structure of a regulating valve of the present invention includes a valve stem 1, a sleeve 2, a valve core 3, a valve seat 4, a valve cover 6 and a valve body 5, and the innermost end of the valve body 5 is a valve Seat 4, spool 3 is located in the valve body 5, the upper part of the valve seat 4, the lower end of the valve stem 1 extends through the valve cover 6 into the valve body 5 to connect with the spool 3, the outside of the spool 3 is provided with a fixed connection Spool protection device 7, sleeve 2 is arranged on the outside of spool protection device 7, the key to its structural design improvement is that a spool protection device 7 is arranged on the periphery of spool 3, and spool protection device 7 and spool 3 are designed as one The position where the valve core protection device 7 is in contact with the valve seat 4 is provided with a guiding structure. in the slot.

[0016] During...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com