Dust removing cloth bag for coal charging car

A coal-charging truck and bagging technology, which is used in charging devices, furnaces to prevent/remove deposits, disperse particle filtration, etc., can solve the problems of increased manufacturing costs, large operating costs, and short service life, and achieves improved dust removal efficiency, Reduce the effect of direct scour and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

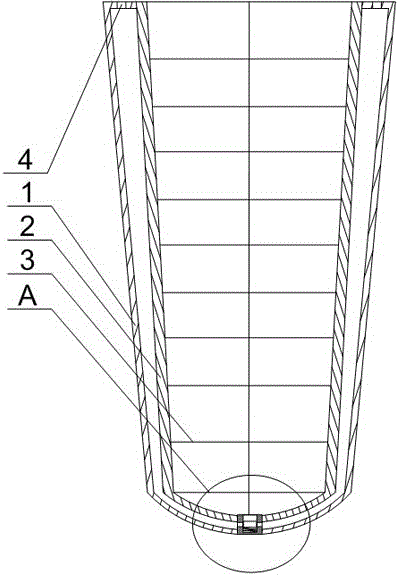

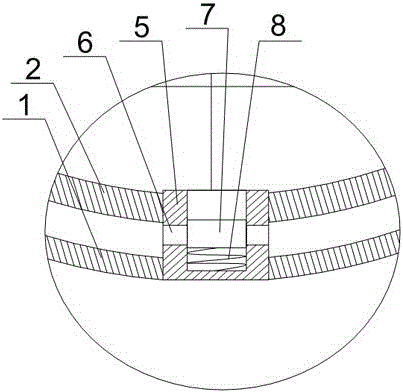

[0020] like figure 1 and figure 2 As shown, the present embodiment includes an outer bag body 1, an inner bag body 2 arranged inside the outer bag body 1, and a frustum-shaped skeleton 3 arranged on the inner wall of the inner bag body 2. The secondary air flow channel is formed in the annular space between them, and an air outlet 4 connected with the secondary air flow channel is opened on the upper end of the outer bag body 1, and a cylinder with an open end is installed between the bottom of the inner bag body 2 and the bottom of the outer bag body 1 5. The open end of the cylinder 5 communicates with the inside of the inner bag 2, and air holes 6 communicating with the secondary air passage are opened on both side walls of the cylinder 5, and the slider 7 is slidably arranged in the cylinder 5 A spring 8 is installed at the bottom of the slider 7. When the inner bag body 2 is in a normal state, the spring 8 supports the slider 7 so that the inside of the inner bag body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com