Wear Mitigation Technology of Double Venturi Structure Nozzle for Regenerated Flue Gas

A technology for regenerating flue gas and Venturi, which is applied in the direction of injection devices, petroleum industry, injection devices, etc., can solve problems such as not being able to meet the three-year service cycle, and achieve the effects of slowing down direct erosion, reducing pressure drop, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

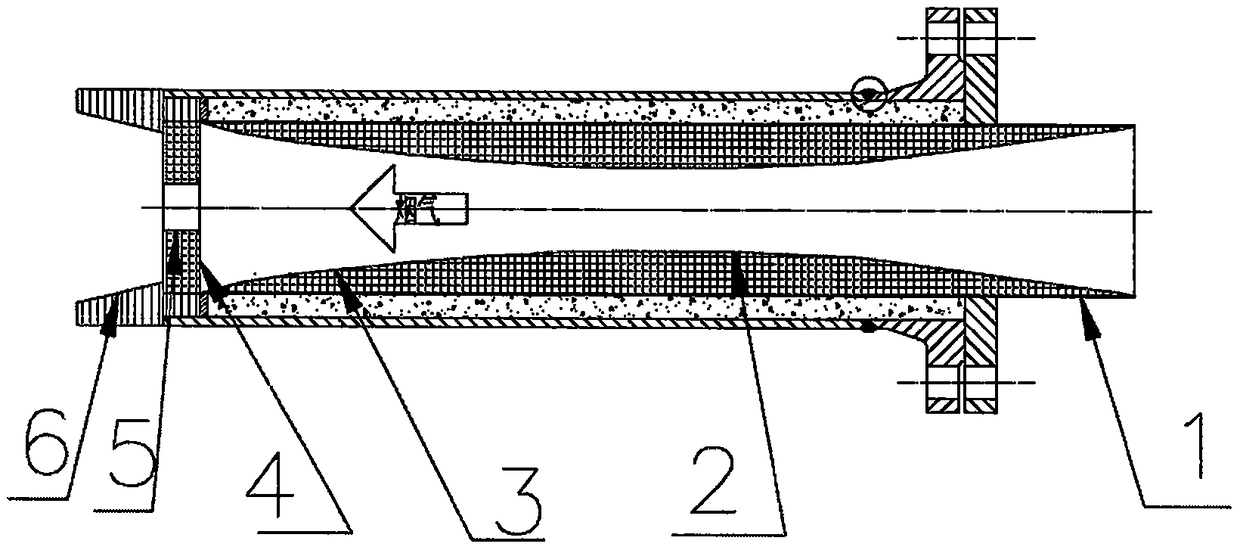

[0015] The inlet of the nozzle device is provided with a first Venturi structure constriction section 1, the middle part is provided with a first Venturi structure throat 2, the nozzle outlet is provided with a first Venturi structure diffusion section 3, and the end of the first Venturi structure diffusion section 3 is provided with a critical The flow velocity nozzle orifice plate 4, the orifice plate throat 5 is arranged in the middle of the critical flow velocity nozzle orifice plate 4, and the second Venturi structure diffusion section 6 is arranged outside the orifice plate throat 5;

[0016] During operation, the flue gas and catalyst enter the first Venturi structure constriction section 1, and enter the first Venturi structure throat 2 through the first Venturi structure constriction section 1, and the first Venturi structure throat 2 compresses the smoke by reducing the diameter. The gas and catalyst generate a pressure drop; after the flue gas and catalyst are accele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com