Regenerating device for ineffective natural gas desulfurization solution

A desulfurization solution and regeneration device technology, applied in the direction of gas fuel, separation method, fuel, etc., can solve the problems of incomplete removal of solid impurity particles, inability to remove organic impurities, and easy breakage of decolorized activated carbon, so as to achieve a more efficient treatment process Flexibility, improved regeneration effect, effect of saving processing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

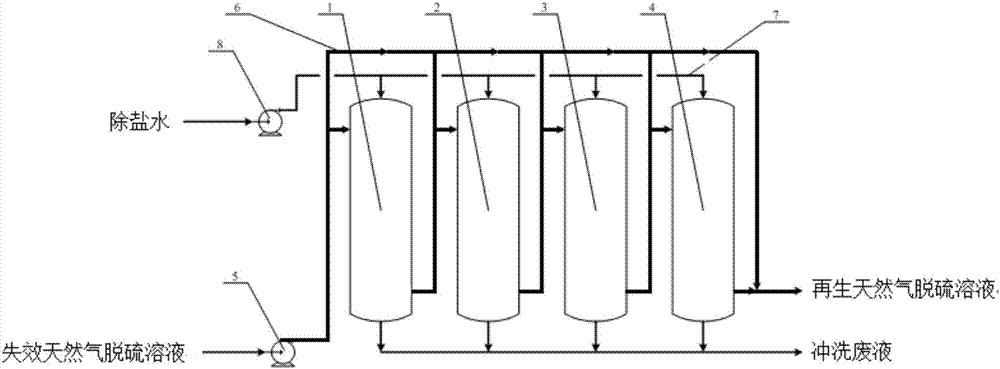

[0031] Such as figure 1As shown, the present invention includes an invalid natural gas delivery pipeline 6 whose input end is connected to the output end of the solution regeneration pump 5, and whose output ends are respectively connected to the solid impurity removal unit 1, the solution decolorization unit 2, and the thermally stable salt removal unit. The liquid inlet of the removal unit 3 and the organic impurity removal unit 4, the liquid outlet of the previous unit in the solid impurity removal unit 1, the solution decolorization unit 2, the heat stable salt removal unit 3 and the organic impurity removal unit 4 It is connected with the liquid inlet of the latter unit, and the output ends of the solid impurity removal unit 1, the solution decolorization unit 2 and the thermal stability salt removal unit 3 are all connected with the fai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com