Hot-blended asphalt regenerant and preparation method thereof

An asphalt rejuvenating agent and solvent refining technology, used in building components, building insulation materials, buildings, etc., can solve the problems of insufficient regeneration depth and poor regeneration effect of aged asphalt, and achieve improved regeneration effect, effect and compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of hot trace asphalt rejuvenator:

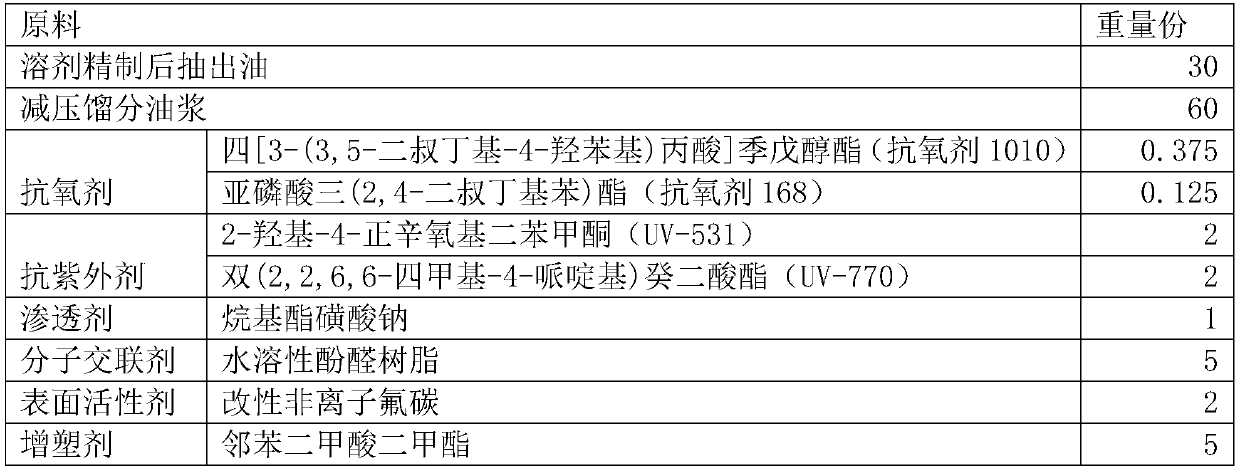

[0030] 1.1 Raw materials, the amount of raw materials is shown in Table 1 below:

[0031] Table 1 Embodiment 1 raw material list:

[0032]

[0033] 1.2 Preparation method, comprising the following steps:

[0034] (1) Add solvent to refine the extracted oil and vacuum distillate slurry into the reactor, heat up to 110°C, and stir for 13 minutes;

[0035] (2) Add surfactant, antioxidant and anti-ultraviolet agent under stirring; then heat up to 155°C, mix and stir for 13 minutes;

[0036] (3) Add plasticizer and molecular cross-linking agent under stirring; then keep the temperature at 155°C and stir for 10 minutes;

[0037] (4) Raise the temperature to 190°C, add the penetrating agent; then stir at 190°C for 28 minutes; cool down to room temperature, and the finished hot asphalt rejuvenator is obtained.

Embodiment 2

[0039] Preparation of hot trace asphalt rejuvenator:

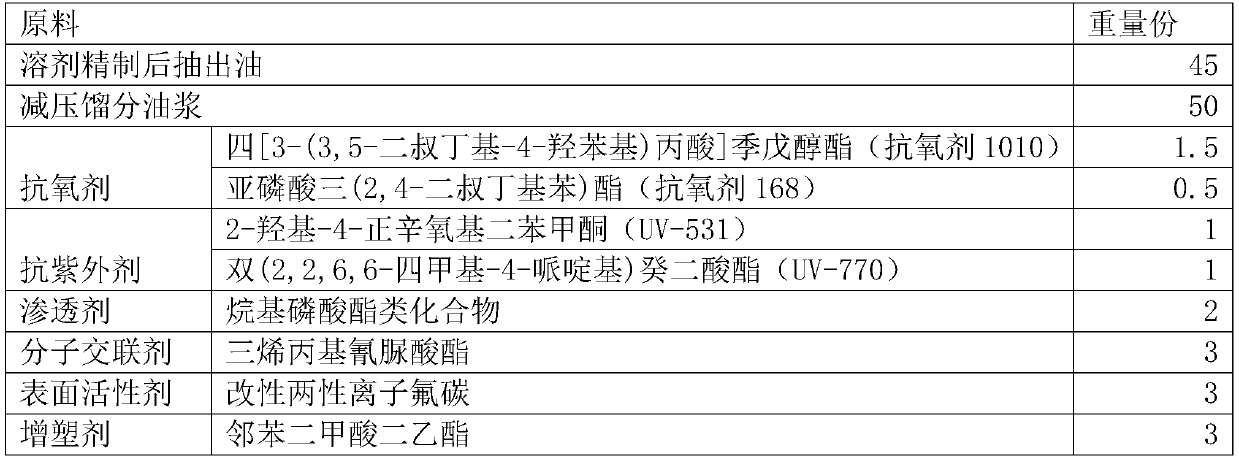

[0040] 2.1 Raw materials, the amount of raw materials is shown in Table 2 below:

[0041] Table 2 Embodiment 2 raw material list:

[0042]

[0043] 2.2 Preparation method, comprising the following steps:

[0044] (1) Add solvent to refine the extracted oil and vacuum distillate oil slurry into the reactor, heat up to 130°C, and stir for 10 minutes;

[0045] (2) Add surfactant, antioxidant and anti-ultraviolet agent under stirring; then raise the temperature to 170°C, and mix and stir for 10 minutes;

[0046] (3) Add plasticizer and molecular cross-linking agent under stirring; then keep the temperature at 170°C and stir for 5 minutes;

[0047] (4) Raise the temperature to 210°C, add the penetrating agent, then stir at 210°C for 20 minutes; cool down to room temperature, and then the finished hot asphalt rejuvenator is prepared.

Embodiment 3

[0049] Preparation of hot trace asphalt rejuvenator:

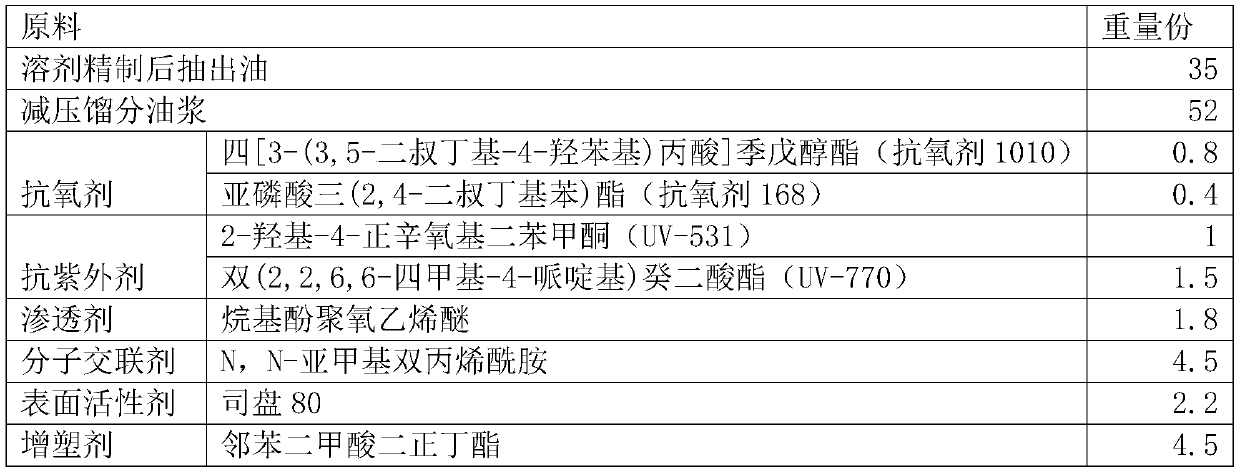

[0050] 3.1 Raw materials, the amount of raw materials is shown in Table 3 below:

[0051] Table 3 Embodiment 3 raw material list:

[0052]

[0053] 3.2 Preparation method, comprising the following steps:

[0054] (1) Add solvent to refine the extracted oil and vacuum distillate oil slurry into the reactor, heat up to 90°C, and stir for 15 minutes;

[0055] (2) Add surfactant, antioxidant and anti-ultraviolet agent under stirring; then heat up to 140°C, mix and stir for 15 minutes;

[0056] (3) Add plasticizer and molecular cross-linking agent under stirring; then keep the temperature at 140°C and stir for 15 minutes;

[0057](4) Raise the temperature to 170°C, add penetrating agent, and then stir at 170°C for 35 minutes; cool down to room temperature, and then the finished hot asphalt rejuvenator is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com