Immersed nozzle of H-shaped leakproof steel

An immersion and nozzle technology, applied in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of continuous casting and pouring, accumulation of inclusions, leakage of casting billets, etc., to reduce the residence time, The effect of eliminating gaps and stabilizing the flow of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

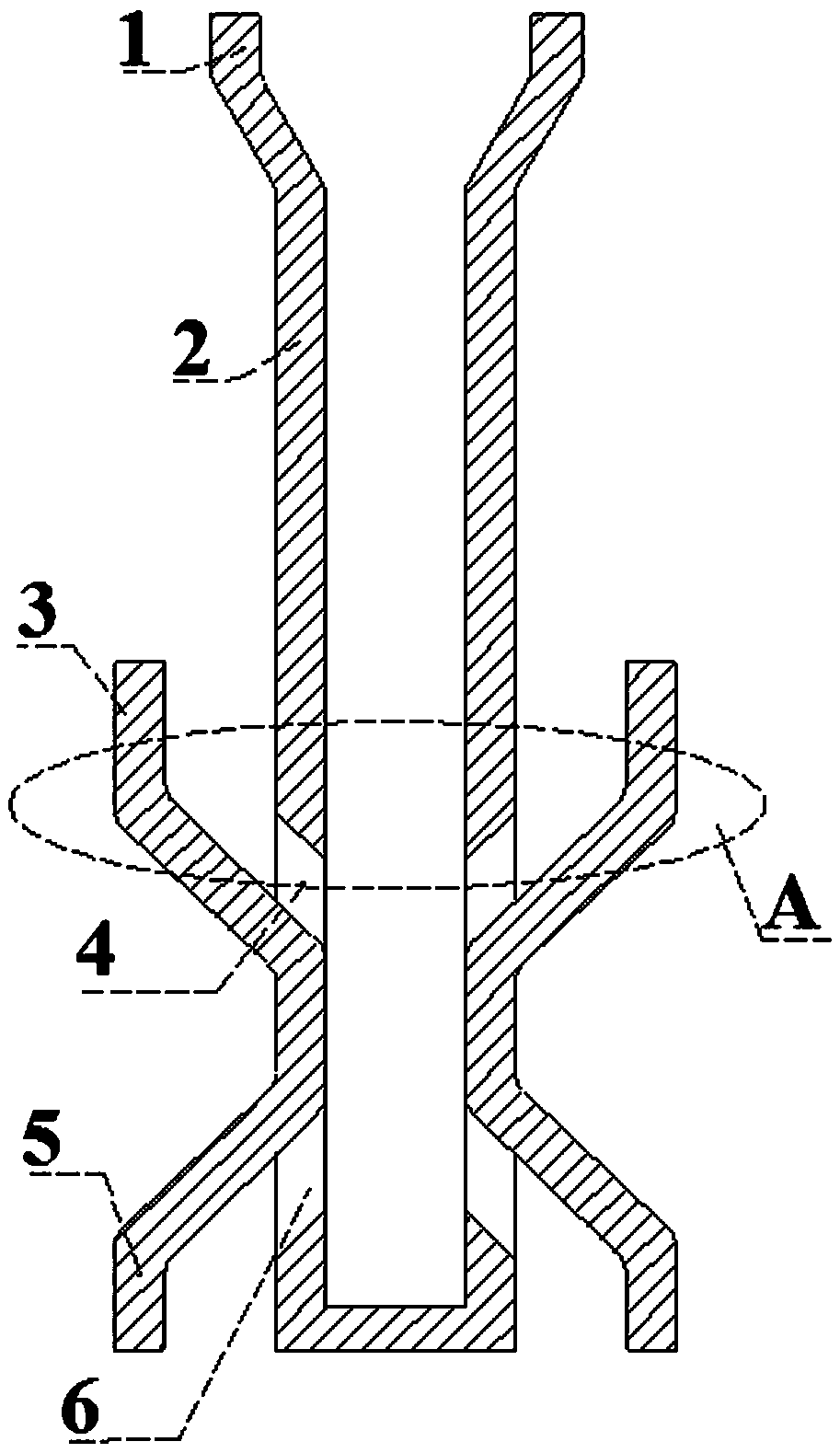

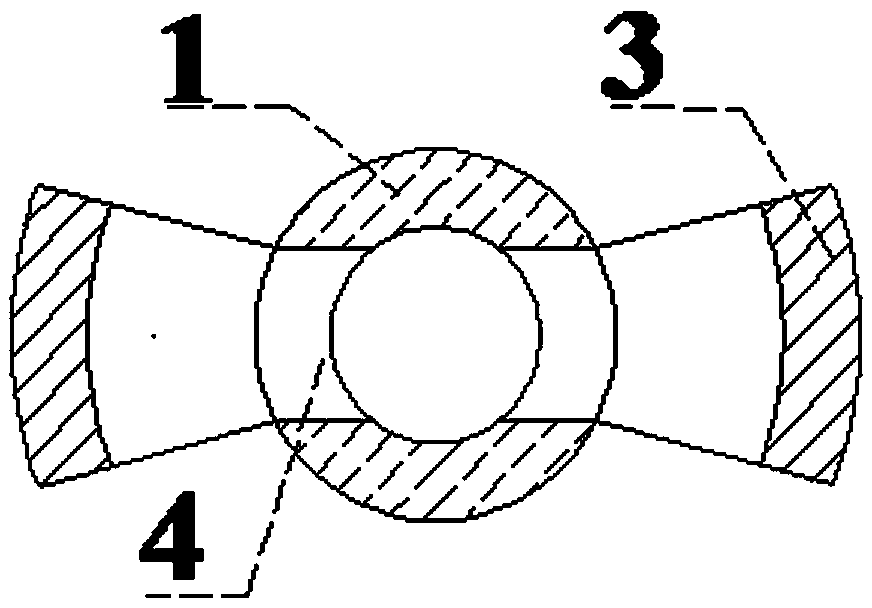

[0027] Such as figure 1 The shown H-shaped leak-proof steel immersion nozzle includes a nozzle main body 2, an upward dam 3, an upwardly inclined steel outlet 4, a downward dam 5, and a downwardly inclined steel outlet 6; the nozzle body The upper part of 2 is the bowl mouth structure 1, the lower part is a hollow cylindrical structure with a smooth inner cavity, and the bottom end is a closed structure; the upper part of the bowl mouth structure 1 is a large-aperture hollow cylinder, and the lower end is a tapered structure. The bottom of the structure is consistent with the inner diameter of the hollow cylindrical structure at the lower part of the nozzle body; the hollow cylindrical structure of the nozzle body 2 is symmetrically provided with a pair of upwardly inclined steel outlets 4 and a hollow cylinder at the lower part of the upwardly inclined steel outlet 4 A pair of upward dams 3 are arranged symmetrically in structure, a pair of downward dams 5 are symmetrically arr...

Embodiment 2

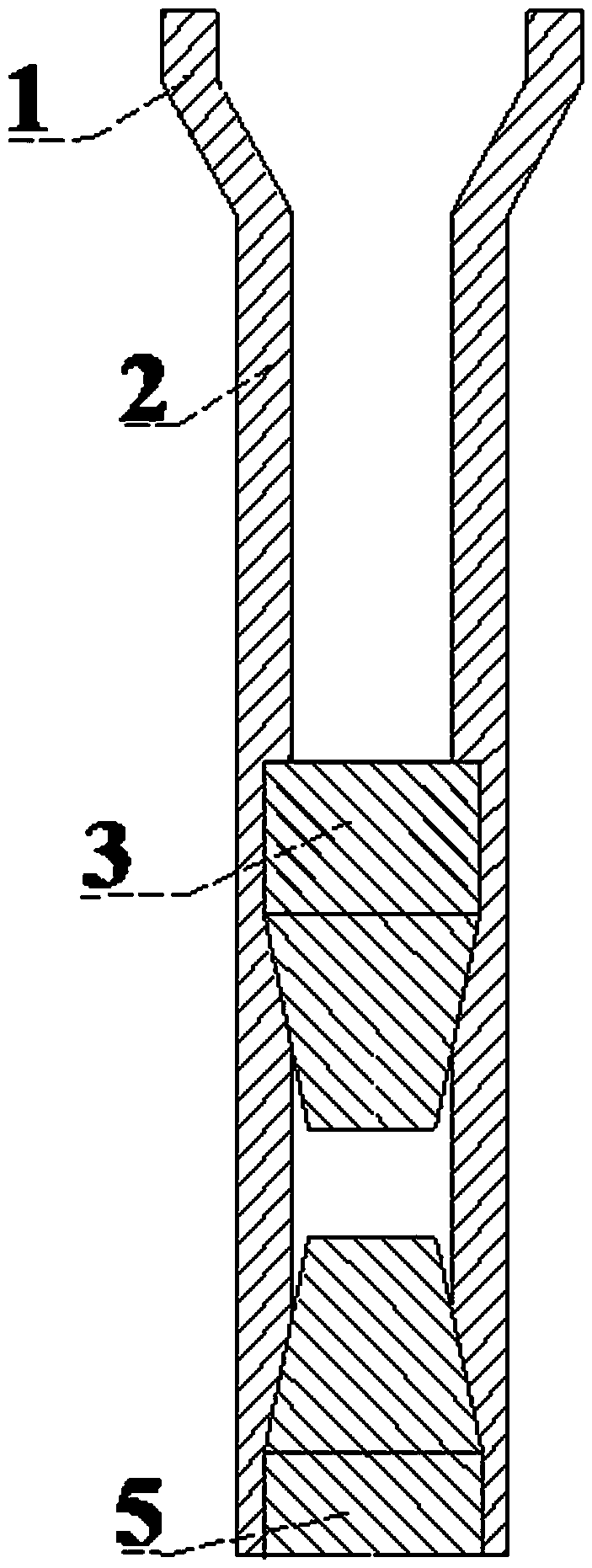

[0030] Such as Figure 4 The shown H-shaped leak-proof steel immersion nozzle includes a nozzle main body 2, an upward dam 3, an upwardly inclined steel outlet 4, a downward dam 5, and a downwardly inclined steel outlet 6; the nozzle body The upper part of 2 is the bowl mouth structure 1, the lower part is a hollow cylindrical structure with a smooth inner cavity, and the bottom end is a concave spherical closed structure; wherein the bowl mouth structure 1 is a conical structure, and the bottom of the conical structure is connected to the hollow cylindrical structure, The inner diameter of the bottom of the conical structure is the same as the inner diameter of the hollow cylindrical structure; the middle and lower parts of the hollow cylindrical structure of the nozzle body 2 are symmetrically provided with a pair of upwardly inclined steel outlets 4, and the hollow at the lower part of the upwardly inclined steel outlet 4 A pair of upward dams 3 are symmetrically arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com