Self-catapulting launching device for guided missile

A technology for launching devices and missiles, applied in the direction of launching devices, etc., can solve the problems of serious impact and ablation of the ship deck, unable to achieve modular installation, endangering the safety of ships and personnel, and achieve good thermal protection effect. , to ensure the emission efficiency and reliability, reduce the effect of impact and ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0040] The principle of the self-ejection launch device is to convert the high-energy gas flow field ejected by the missile engine into the ejection power of the missile in the limited space formed by the bottom of the barrel and the adapter.

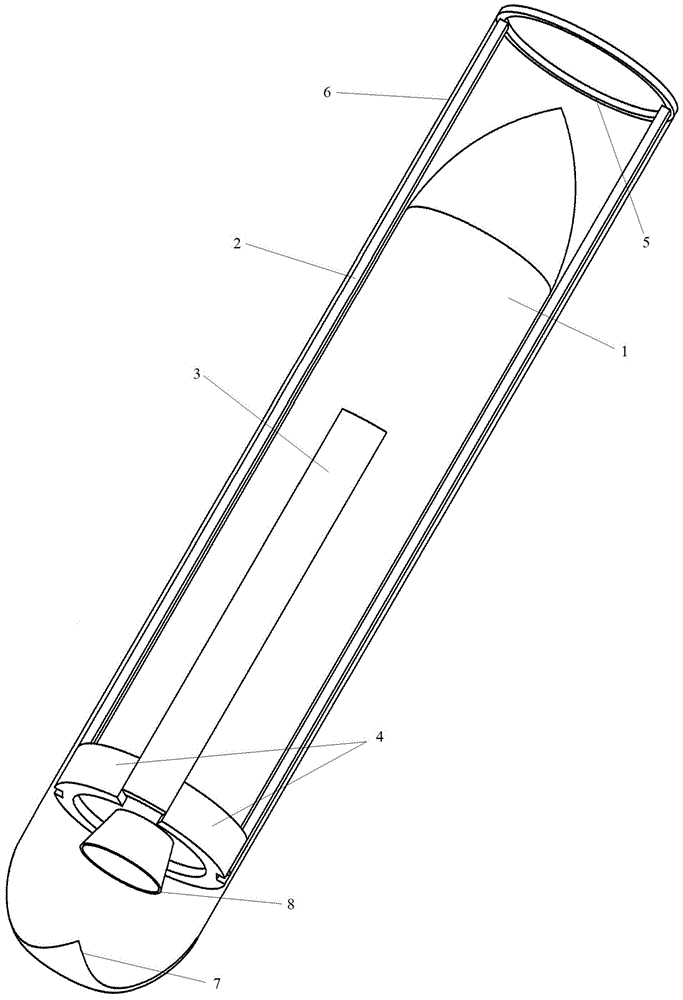

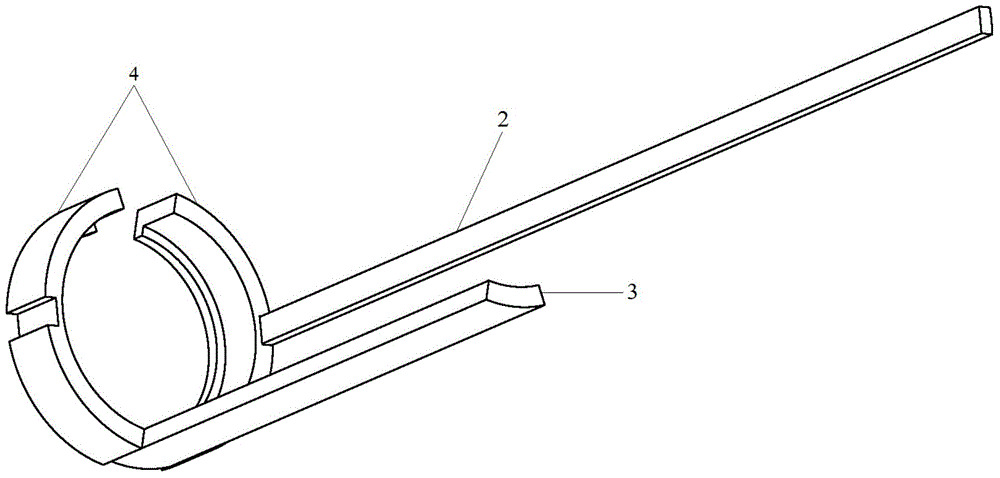

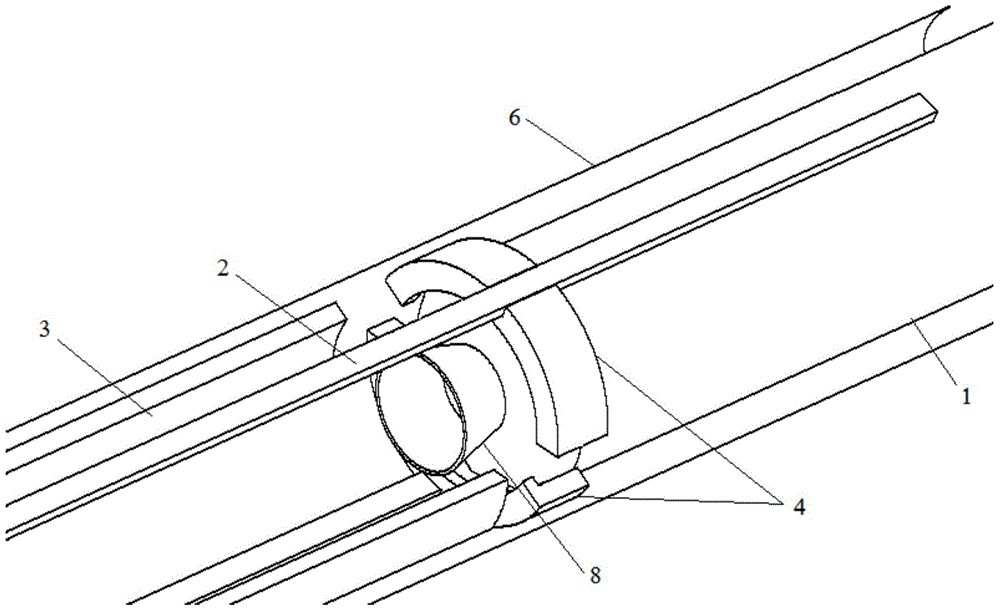

[0041] The invention provides a missile self-ejection launching device, comprising a guide cone (7), a limit mechanism, a buffer device (5), two long guide rails (2), two short guide rails (3) and two adapters ( 4);

[0042] The diversion cone (7) is a metal cone or a cone-like.

[0043] Buffer device (5) is a metal ring.

[0044] The stop mechanism is a metal ring that holds the adapter.

[0045] The length of the short guide rail (3) is between 1 / 3 and 2 / 3 of the length of the long guide rail (2).

[0046] The adapter (4) is a ring structure, and a groove is arranged in the middle of the outer edge of the ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com