Efficient cooling blade for gas turbine engine

A gas turbine, cooling blade technology, applied in engine components, engine functions, machines/engines, etc., can solve problems such as high thermal load, threatening the safe and stable operation of gas turbine engines, avoid temperature unevenness, and improve wall adhesion And the effect of ductility and uniform gas film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

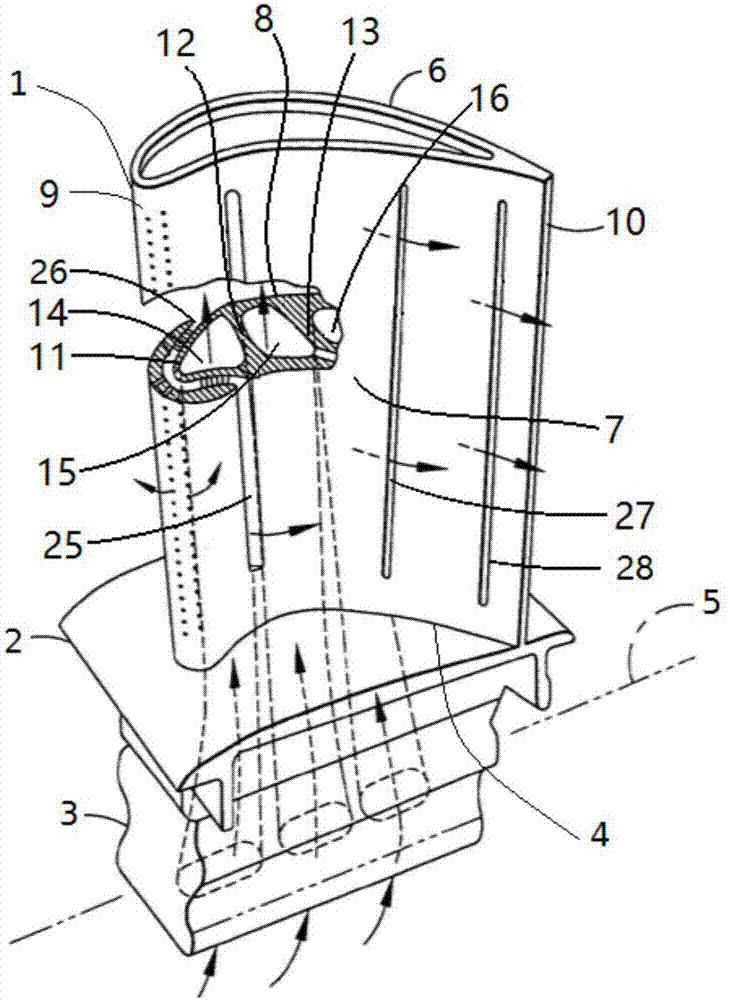

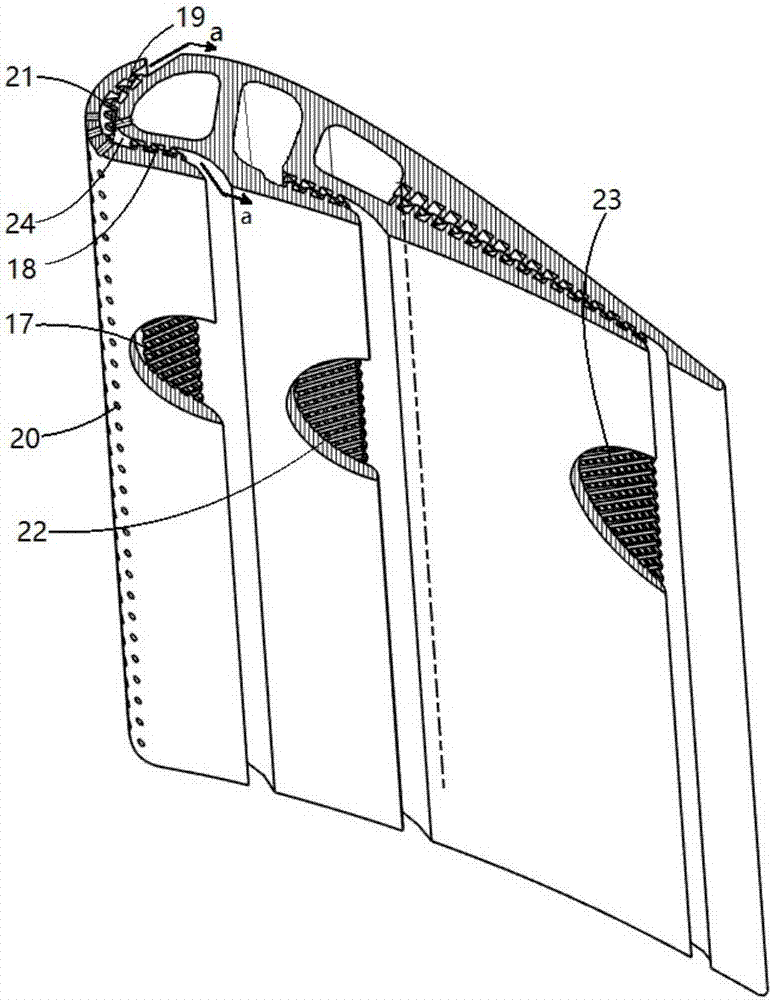

[0033] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0034] Such as figure 1 with figure 2 As shown, the present invention discloses a high-efficiency cooling blade for a gas turbine engine, which includes a blade body, an end wall, and a tenon connected in sequence, and the tenon is used to connect with the turbine disk;

[0035] The blade body is a hollow cylinder, including a pressure surface and a suction surface;

[0036] Both the pressure surface and the suction surface are arc surfaces, wherein the suction surface is arranged outside the pressure surface, and both sides of the suction surface are respectively connected with both sides of the pressure surface to form a blade leading edge and a blade trailing edge;

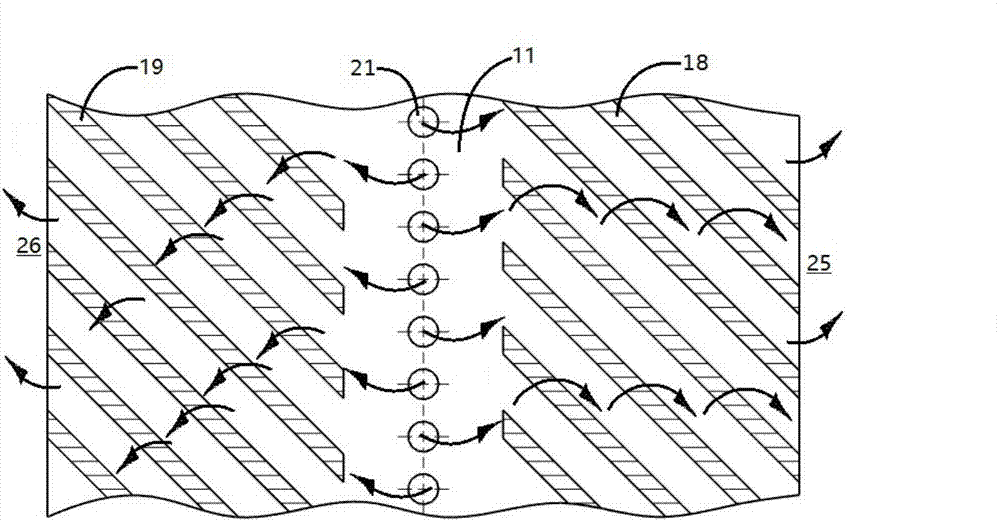

[0037] First to third bridging beams are sequentially provided in the blade body from the leading edge of the blade to the trailing edge of the blade, and the first to third brid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com