Thermal barrier coating with thermal radiation property as well and preparation method of thermal barrier coating

A thermal barrier coating, thermal radiation technology, applied in the direction of coating, metal material coating process, climate sustainability, etc. It can meet the protection requirements and attenuation of titanium alloy materials on the outer surface of the cavity of the super aircraft, and achieve the effects of good bonding, increasing density and reducing roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

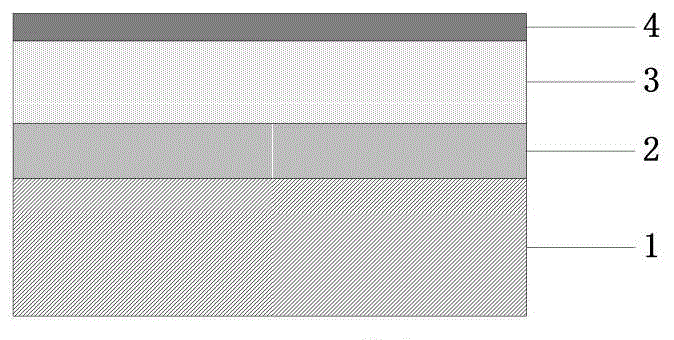

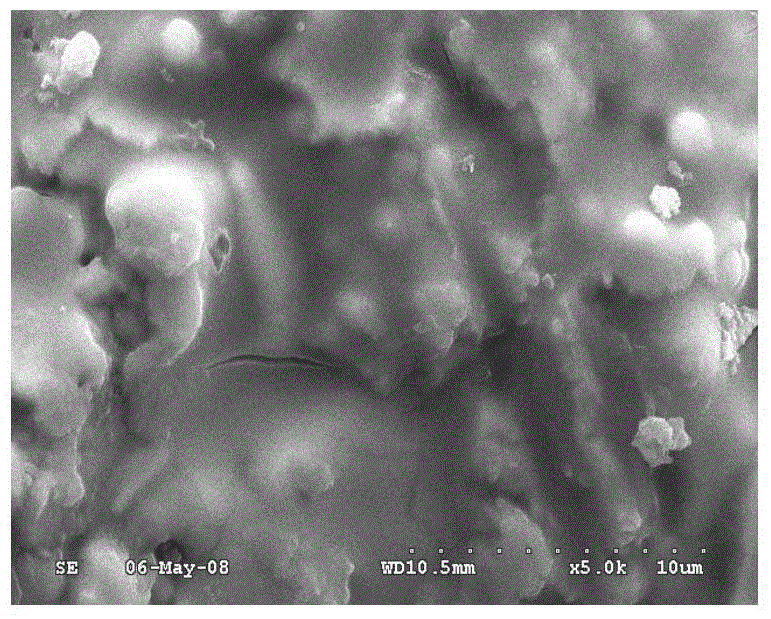

[0029] A thermal barrier coating with thermal radiation performance, the coating is divided into three layers, from the outside to the inside are the sealing heat dissipation layer, the ceramic layer and the bonding layer. Chemical composition: the sealing heat dissipation layer is SiO 2 ; The ceramic layer is 6-8% Y 2 o 3 , 92-94% ZrO 2 ; The bonding layer is NiCrAlY alloy, its composition is 70-72% Ni, 21.3-24.5% Cr, 5-6% Al, 0.5-0.7% Y. Coating thickness: sealing heat dissipation layer 4-6μm; ceramic layer 200-300μm; bonding layer 80-150μm.

[0030] A method for preparing a thermal barrier coating with thermal radiation performance, comprising the following steps:

[0031] (1) Perform conventional pretreatment on workpieces before thermal spraying, such as degreasing, derusting, and sandblasting.

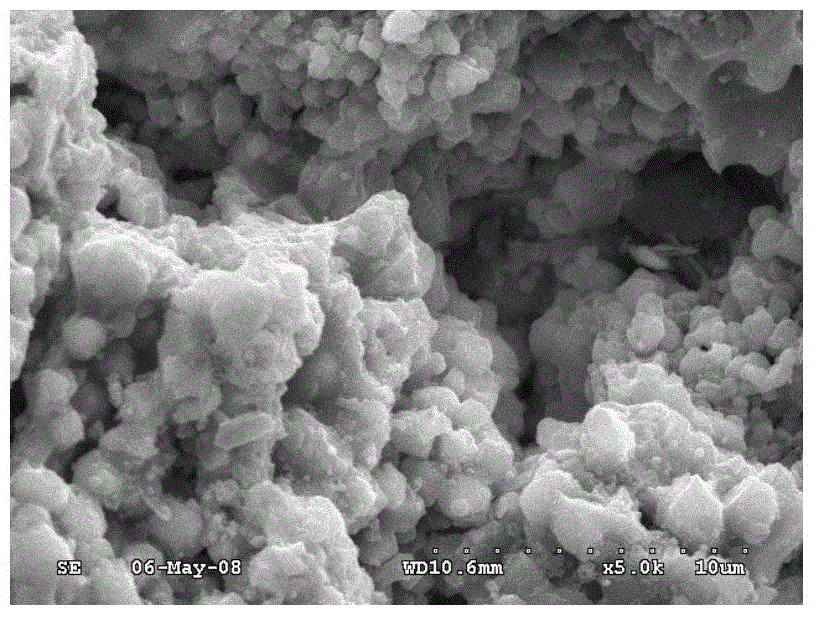

[0032](2) Spray the NiCrAlY adhesive layer on the surface of the pretreated workpiece with supersonic flame (HVOF). The chemical composition of the NiCrAlY adhesive layer is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com