Bus connector

A busbar connector, plug-in technology, applied in the direction of connection, busbar installation, two-component connection device, etc., can solve the problems of reducing production efficiency, increasing difficulty, weak insulation protection ability of connecting conductors, etc., and achieving enhanced insulation protection ability. , to meet the effect of insulation grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

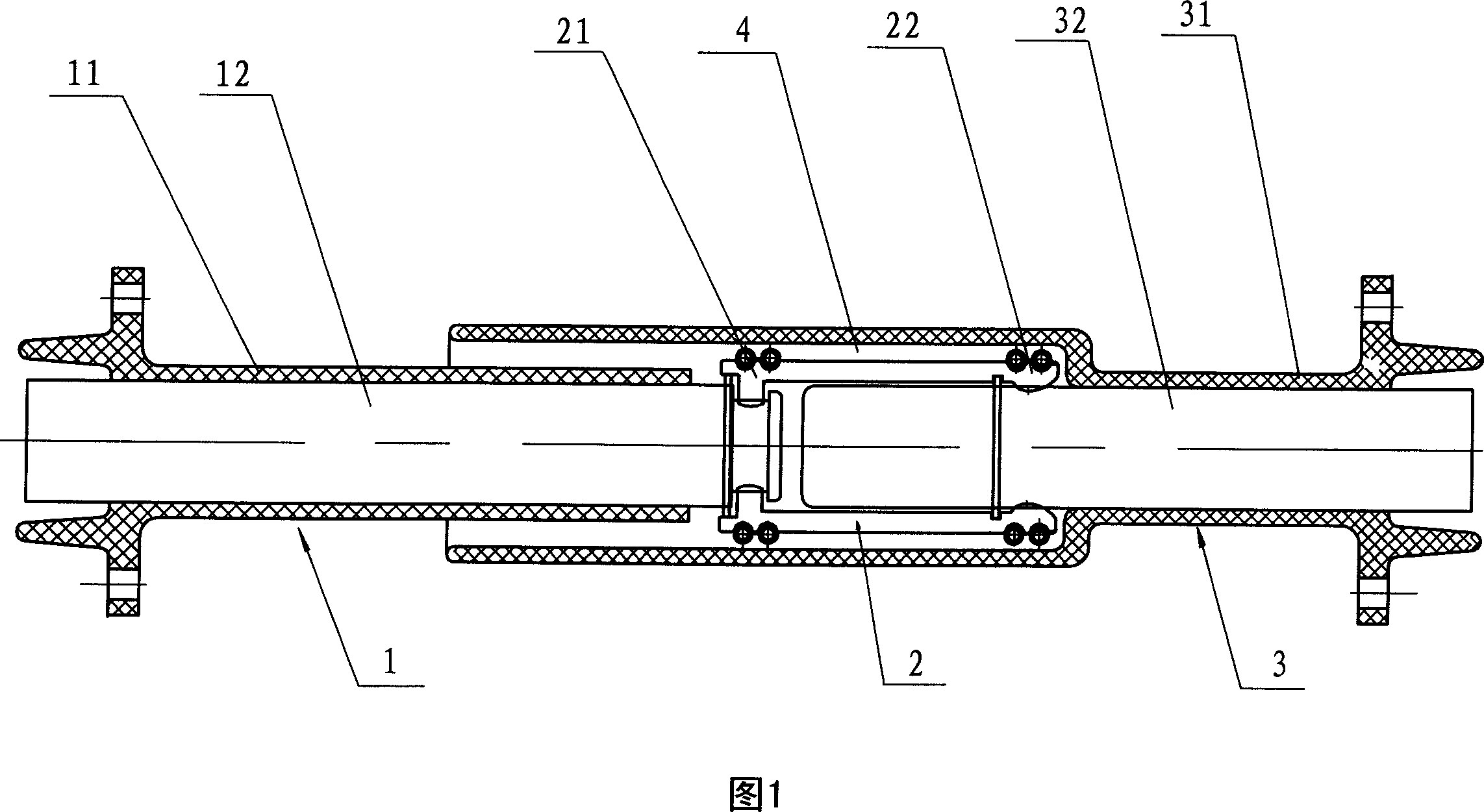

[0007] As shown in the figure, the busbar connector of the present invention is composed of a fixed guide arm 1 , a plug-in contact 2 and a sliding guide arm 3 . The plug-in contact is a type of contact that may be connected to other conductors in a plug-in manner, such as a plum blossom contact and the like. The fixed guide arm is composed of a fixed insulating sleeve 11 and a fixed conductor 12, and the sliding guide arm is composed of a sliding insulating sleeve 31 and a sliding conductor 32. For connection, the inner ends of the fixed conductor 12 and the sliding conductor 32 are respectively connected to the fixed connection end 21 and the insertion end 22 of the plug-in contact 2, and the sliding conductor can move back and forth in the plug-in contact to change the conductive part. The total length to meet the connection needs of high-voltage terminals with different spacing. The inner end of the sliding insulating sleeve 31 is provided with an insulating protection ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com