Permanent magnet bearing squeeze film dumper with elastic ring

A technology of squeezing oil film damping and permanent magnet bearings, applied in the directions of bearings, shafts and bearings, springs/shock absorbers, etc., can solve the problems of low frequency precession, poor anti-overturning ability, high machining accuracy, and reduce the hoop tension Stress, lower manufacturing cost, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

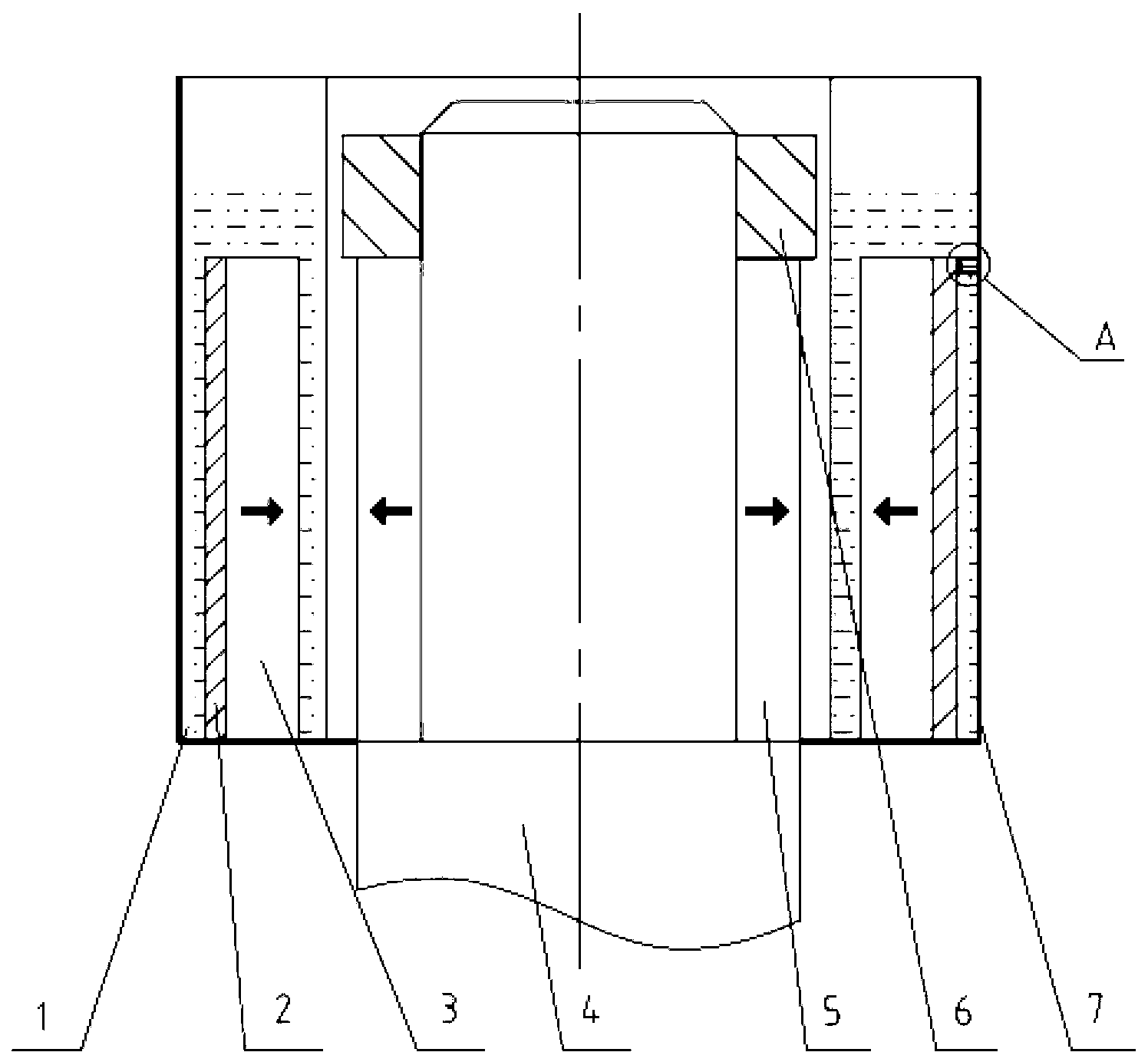

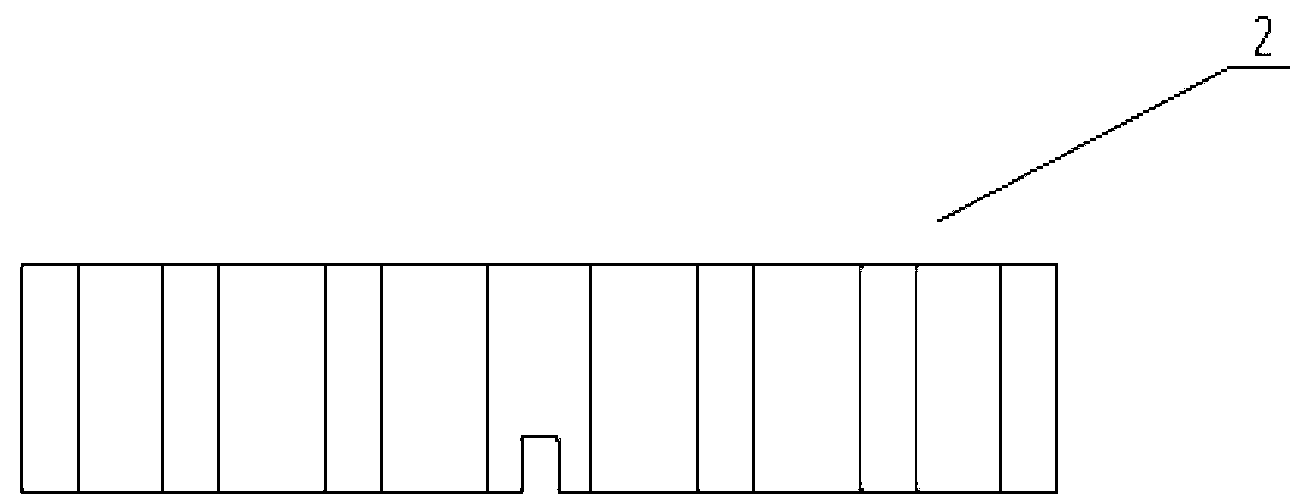

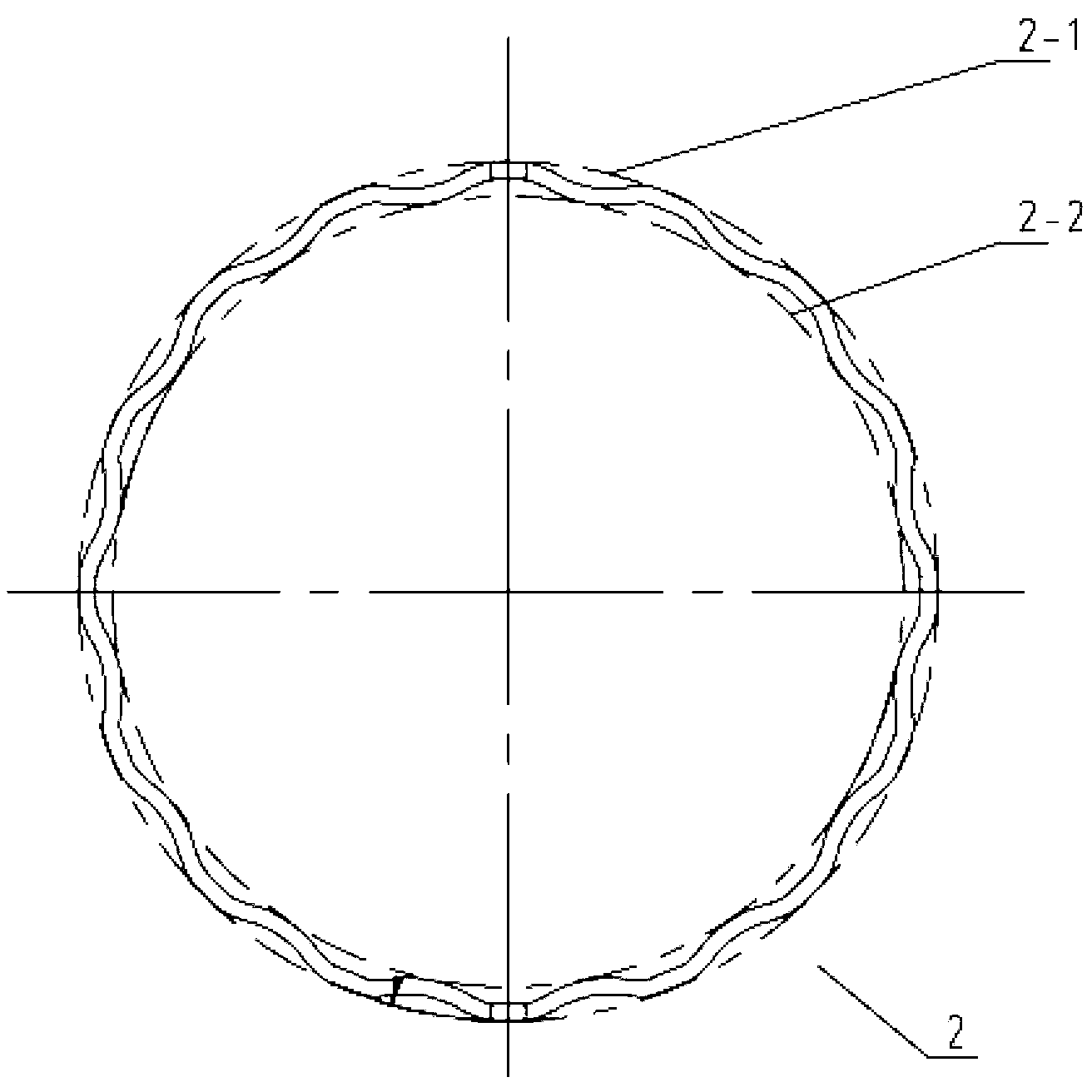

[0031] Such as Figure 1~6 As shown, a permanent magnet bearing squeeze oil film damper with an elastic ring includes a bearing outer ring 3, a bearing inner ring 5 fixedly set on the shafting 4, and a lubricating oil cavity 7 filled with lubricating oil 1, and the bearing outer ring The ring 3 is installed in the lubricating oil cavity 7, and also includes the elastic ring 2, the bearing inner ring 5 and the bearing outer ring 3 are both radially magnetized, and the opposite sides of the bearing inner ring 5 and the bearing outer ring 3 after magnetization For the same magnetic pole, there is an air gap between the bearing inner ring 5 and the bearing outer ring 3, the inner ring of the elastic ring 2 is in contact with the outer ring of the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com